Multifunctional surface treatment for textiles

Inactive Publication Date: 2004-06-24

THE HONG KONG POLYTECHNIC UNIV

View PDF3 Cites 19 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

[0005] It is an object of the present invention to provide a simple process for coating textile surfaces with a continuous metal oxide without altering the appearance of the textile.

Problems solved by technology

Present technologies such as impregnation coating of dispersed nanoparticles suffer from low adhesion between the oxide coating and the textile surface and hence poor wash-fastness results.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0023] A cotton substrate of 10.times.10 cm was dried at 100.degree. C. for 10 minutes. The dried cotton substrate was then dip-coated in the prepared sol for 30 seconds, padded at 2,7 kg per square centimetre and dried at 80.degree. C. for 10 minutes and then finally cured at 150.degree. C. for five minutes.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Login to View More

Abstract

Description

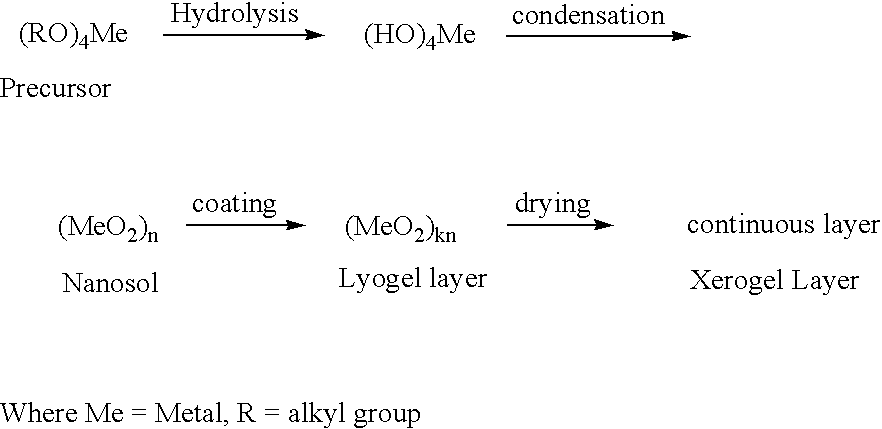

[0001] The present invention relates to multifunctional nanostructural surface treatment for textiles. More particularly, although not exclusively, the invention relates to the surface treatment of textiles adopting a Sol-gel reaction scheme. The invention relates to a simple, fast and low-cost finishing process for textiles using a metal oxide matrix providing improved surface properties. Properties to be improved might be ultraviolet filtering, hydrophilicity, self-cleaning, antimicrobial and deodorising characteristics.[0002] Applications of the invention exist in the production of smart textiles with tailor-made end uses addressing environmental protection and hygienic aspects.[0003] Present technologies such as impregnation coating of dispersed nanoparticles suffer from low adhesion between the oxide coating and the textile surface and hence poor wash-fastness results. The present invention, on the other hand allows for chemical bonding between the oxide matrix and the textile ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D06M11/36D06M11/46

CPCD06M11/36D06M11/46D06M2400/02D06M2200/25D06M2200/00

Inventor XIN, JOHN HAOZHONGDAOUD, WALID ABDELHAMIDTAO, XIAO MING

Owner THE HONG KONG POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com