Preparation method for sludge baked brick resisting leaching of heavy metal

A technology of heavy metals and sintered bricks, which is applied in chemical instruments and methods, sludge treatment, clay products, etc., can solve the problems of slow leaching of heavy metals, danger of heavy metal leaching, control and improvement, etc., and achieves simple preparation methods and remarkable treatment effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Raw material to be processed: ordinary river sludge 2Kg.

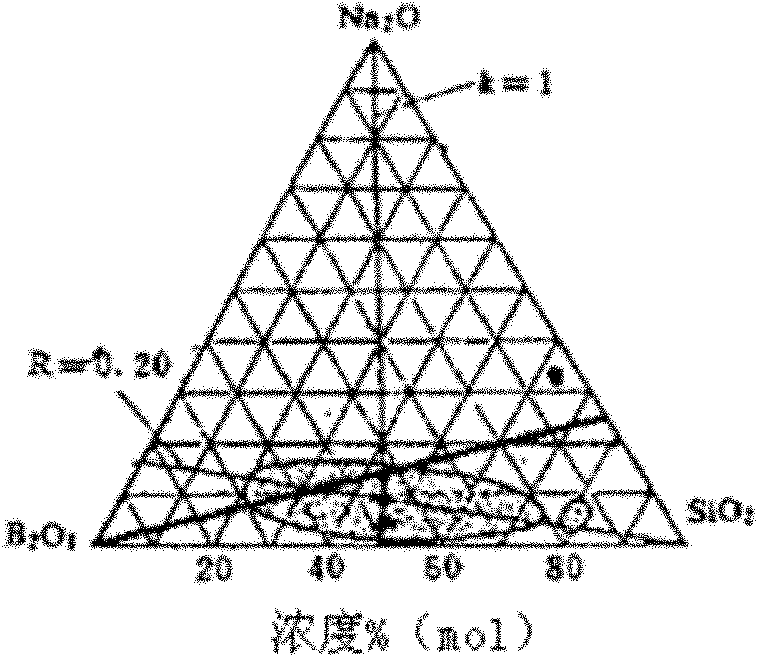

[0023] Boric acid is added to water glass, stirred at 50-60° C. to obtain a sodium borosilicate ternary sol collagen solution; water is added and mixed to obtain a sodium borosilicate ternary sol dilution with a sol concentration of 12 wt%.

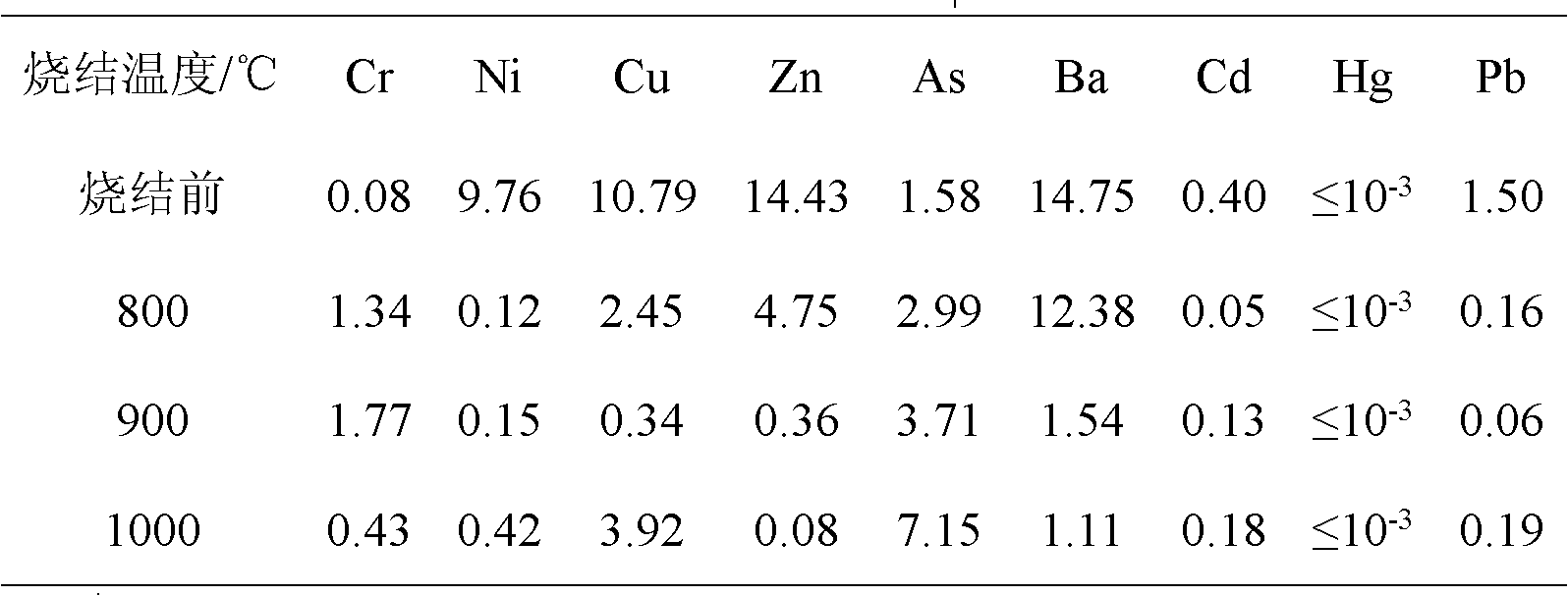

[0024] Treatment steps: After the sludge is retrieved, it will be treated with impurity removal and aging, and then divided into two groups on average. One group was added with 100 g sodium borosilicate ternary sol diluted to 10 wt%, stirred for 6 hours, and left to stand for 24 hours, while the other group was added with the same amount of water. The two groups of sludge were hand-pressed with a 40mm×40mm×160mm triple mold, left to air at room temperature, put into a constant temperature drying oven after demoulding, dried at 110°C for 24 hours, and then put into a box-type resistance furnace for roasting and sintering The maximum temperature is 800°C, and it is cooled wi...

Embodiment 2

[0027] Raw material to be treated: 2.5Kg of river sludge with high arsenic content.

[0028] Adding boric acid into water glass, stirring at 50-60 DEG C to obtain a sodium borosilicate ternary sol collagen solution; adding water and mixing to obtain a sodium borosilicate ternary sol dilution with a sol concentration of 10 wt%.

[0029] Treatment steps: After the sludge is retrieved, it will be treated with impurity removal and aging, and then divided into two groups on average. One group was added with 100 g sodium borosilicate ternary sol diluted to 10 wt%, stirred for 6 hours, and left to stand for 24 hours, while the other group was added with the same amount of water. The two groups of sludge were hand-pressed with a 40mm×40mm×160mm triple mold, left to air at room temperature, put into a constant temperature drying oven after demoulding, dried at 110°C for 24 hours, and then put into a box-type resistance furnace for roasting and sintering The maximum temperature is 800°...

Embodiment 3

[0032] Raw material to be processed: 1.3Kg of river sludge with high chromium content.

[0033] Adding boric acid into water glass, stirring at 50-60 DEG C to obtain a sodium borosilicate ternary sol collagen solution; adding water and mixing to obtain a sodium borosilicate ternary sol dilution with a sol concentration of 10 wt%.

[0034] Treatment steps: After the sludge is retrieved, it will be treated with impurity removal and aging, and then divided into two groups on average. One group was added with 100 g sodium borosilicate ternary sol diluted to 10 wt%, stirred for 6 hours, and left to stand for 24 hours, while the other group was added with the same amount of water. The two groups of sludge were hand-pressed with a 40mm×40mm×160mm triple mold, left to air at room temperature, put into a constant temperature drying oven after demoulding, dried at 110°C for 24 hours, and then put into a box-type resistance furnace for roasting and sintering The maximum temperature is 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com