Wheel spoke and production method thereof

A production method and spoke technology, which is applied in the direction of wheels, web-type wheels, vehicle parts, etc., can solve the problems of high production cost, complicated process, and increase the quality of wheel spokes, so as to reduce the increase in quality, improve overall performance, and strengthen strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 of the present application provides a wheel spoke, and specific embodiments of the wheel spoke are as follows:

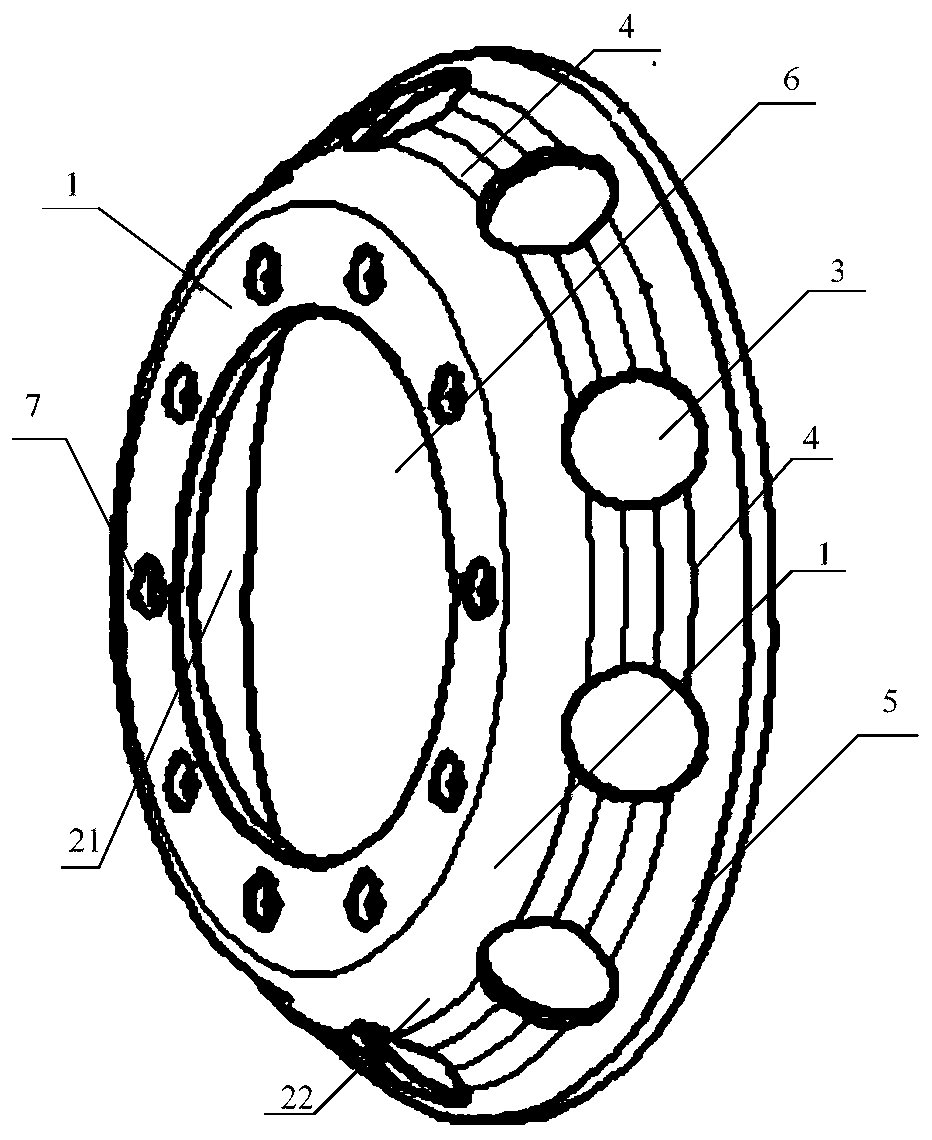

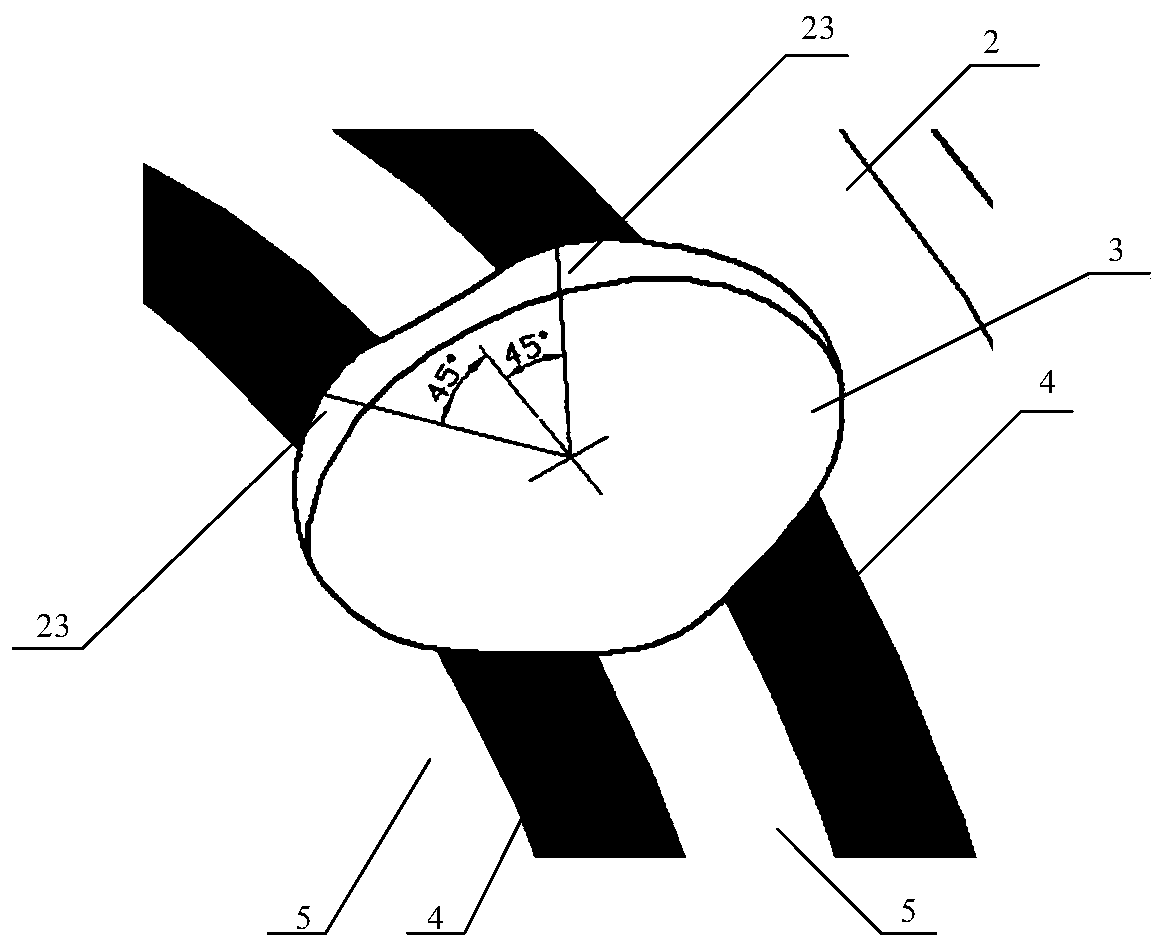

[0038] The following combination Figure 1 to Figure 2 The wheel spokes provided by this application are described.

[0039] Please refer to figure 1 , which shows a schematic structural diagram of the wheel spoke provided in Embodiment 1 of the present application. The wheel spoke provided by the embodiment of the present application includes: a mounting surface 1 located in the center, and a spinning surface 2 located on the outer periphery and forming a set angle with the mounting surface 1 . Wherein, a plurality of cooling holes 3 are arranged on the spinning surface 2 along the circumferential direction.

[0040] The spokes are an integral part of the wheel, which together with the rim form the whole of the wheel. When connecting the wheel spokes and the rim, it is necessary to connect the outer surface 22 of the edge of the spokes with ...

Embodiment 2

[0051] In the foregoing embodiments, a spoke of a wheel is provided, and correspondingly, Embodiment 2 of the present application provides a method for producing a spoke of a wheel. This method embodiment is used to produce the product in the product embodiment, and for relevant information, please refer to the part of the description of the product embodiment.

[0052] The specific embodiment of the production method of this wheel spoke is as follows:

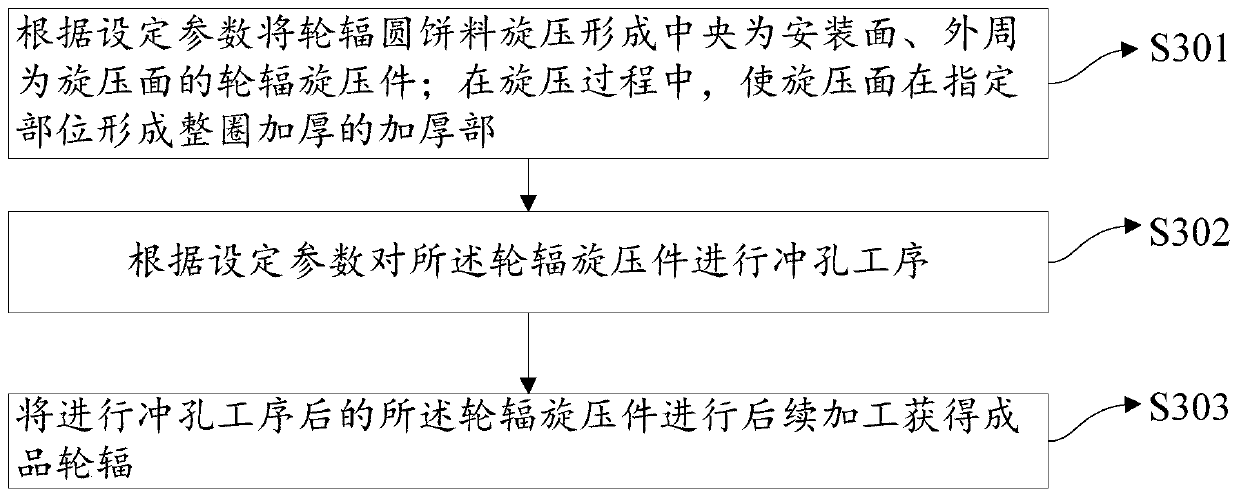

[0053] refer to image 3 , which shows a production flow chart of a wheel spoke provided in Embodiment 2 of the present application. Embodiment 2 of the present application specifically takes the production of commercial vehicles as an example, and describes the production method of the wheel spokes in detail. The steps of the production method of the wheel spokes are as follows:

[0054] Step S301: Spin the spoke circular cake material according to the set parameters to form a spoke spinning part with the center as the moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com