Top-grade sunproof wool fabric for automotive interior

A car interior and sun-resistant technology, which is applied in the direction of animal fibers, wear-resistant fibers, light-resistant fibers, etc., can solve the problems of poor light stability, low light fastness of wool, and easy color changes, etc., to achieve light Good stability and easy dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

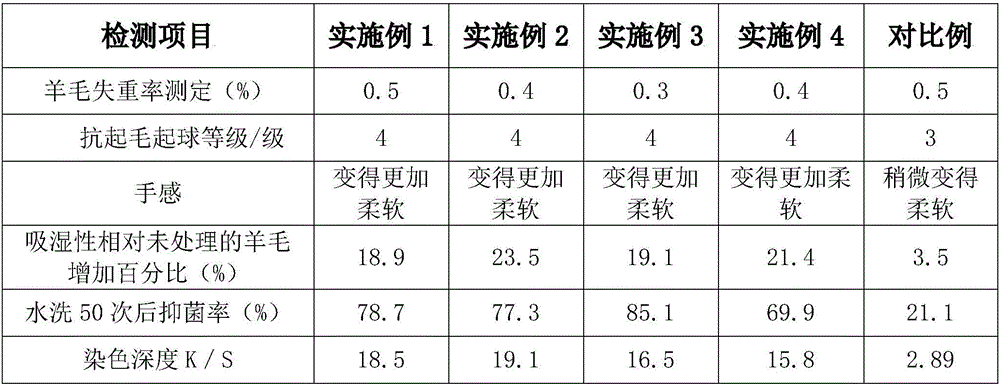

Examples

Embodiment 1

[0030] A high-grade sun-resistant wool fabric for automotive interiors, the production method of which is as follows:

[0031] (1) Wool fiber washing pretreatment:

[0032] Select high-quality wool fibers and perform three washing pretreatments:

[0033] The first time: 0.5% citric acid, the water temperature is kept at 45°C; the pH is controlled at 7, and the treatment time is 30 minutes;

[0034] The second time: 1.2% glucoamylase, the water temperature was kept at 35°C; the pH was controlled at 7, and the treatment time was 10 minutes;

[0035] The third time: Rinse with pure water, control the temperature at 55°C, and dry at low temperature;

[0036] Washed pre-treated wool fibers have been freed of various dirt and chemically altered;

[0037] (2) Microbial fermentation treatment:

[0038] Acetobacter, Lactobacillus acidophilus, and Bacillus amyloliquefaciens were prepared according to the ratio of 1:0.3:0.7 to 1.1*10 5 The bacterial suspension, the bacterial suspens...

Embodiment 2

[0048] A high-grade sun-resistant wool fabric for automotive interiors, the production method of which is as follows:

[0049] (1) Wool fiber washing pretreatment:

[0050] Select high-quality wool fibers and perform three washing pretreatments:

[0051] The first time: 0.8% citric acid, the water temperature was kept at 45°C; the pH was controlled at 7, and the treatment time was 30 minutes;

[0052] The second time: 0.8% glucoamylase, the water temperature was kept at 35°C; the pH was controlled at 7, and the treatment time was 10 minutes;

[0053] The third time: Rinse with pure water, control the temperature at 55°C, and dry at low temperature;

[0054] Washed pre-treated wool fibers have been freed of various dirt and chemically altered;

[0055] (2) Microbial fermentation treatment:

[0056] Acetobacter, Lactobacillus acidophilus, and Bacillus amyloliquefaciens were prepared according to the strain ratio of 1:0.5:0.5 to make 1.1*10 5 The bacterial suspension, the ba...

Embodiment 3

[0066]A high-grade sun-resistant wool fabric for automotive interiors, the production method of which is as follows:

[0067] (1) Wool fiber washing pretreatment:

[0068] Select high-quality wool fibers and perform three washing pretreatments:

[0069] The first time: 0.6% citric acid, the water temperature was kept at 45°C; the pH was controlled at 7, and the treatment time was 30 minutes;

[0070] The second time: 1.1% glucoamylase, the water temperature was kept at 35°C; the pH was controlled at 7, and the treatment time was 10 minutes;

[0071] The third time: Rinse with pure water, control the temperature at 55°C, and dry at low temperature;

[0072] Washed pre-treated wool fibers have been freed of various dirt and chemically altered;

[0073] (2) Microbial fermentation treatment:

[0074] Acetobacter, Lactobacillus acidophilus, and Bacillus amyloliquefaciens were prepared according to the ratio of 1:0.4:0.6 to 1.1*10 5 The bacterial suspension, the bacterial suspe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com