High-heeled shoe heel

A technology for high-heeled shoes and heels, applied in the field of high-heeled shoes heels, can solve the problems of easy gaps in boring holes, broken support inserts, insufficient screw-in strength, etc., and achieve the effects of improving connection strength, facilitating positioning and matching, and ensuring accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

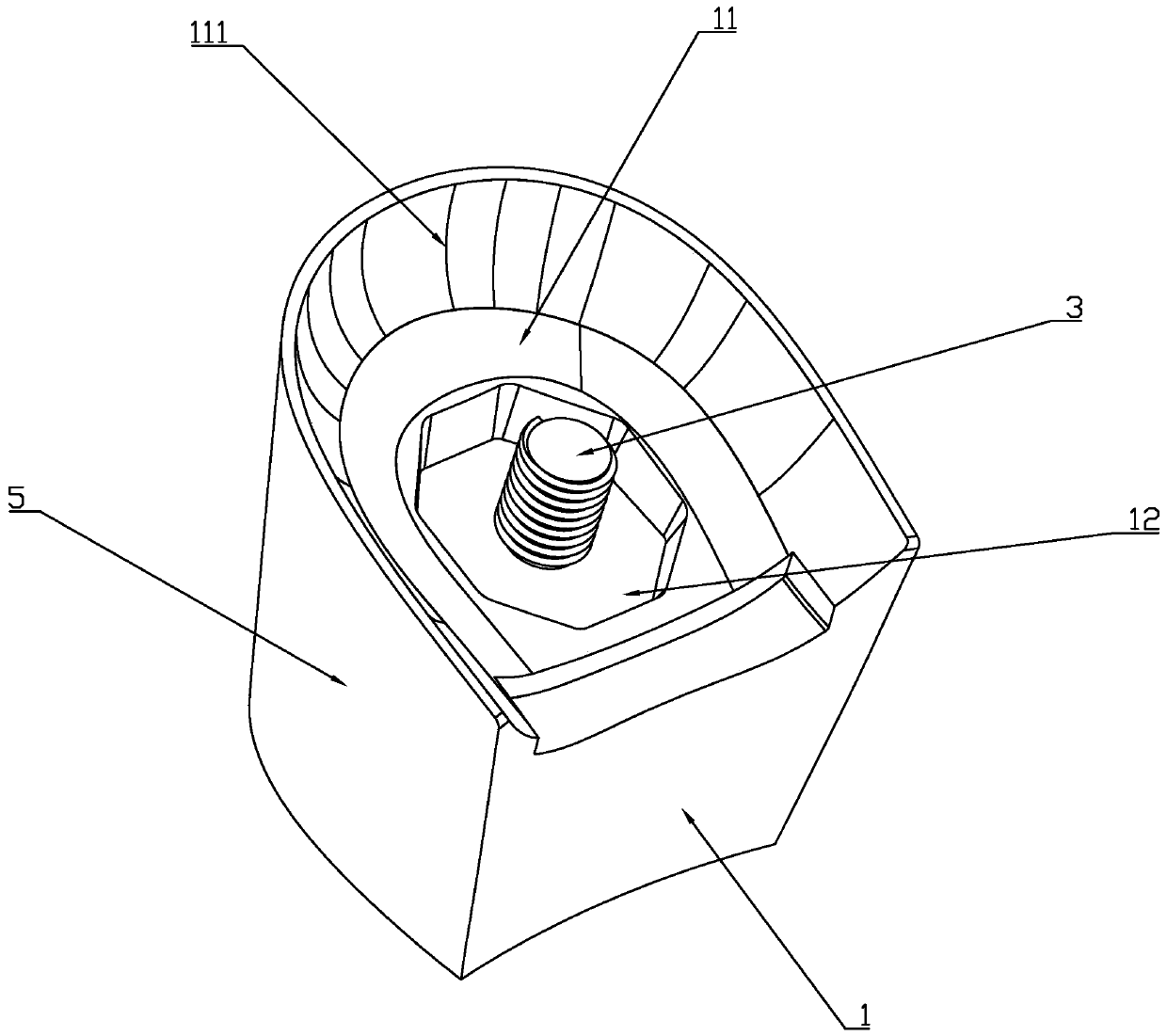

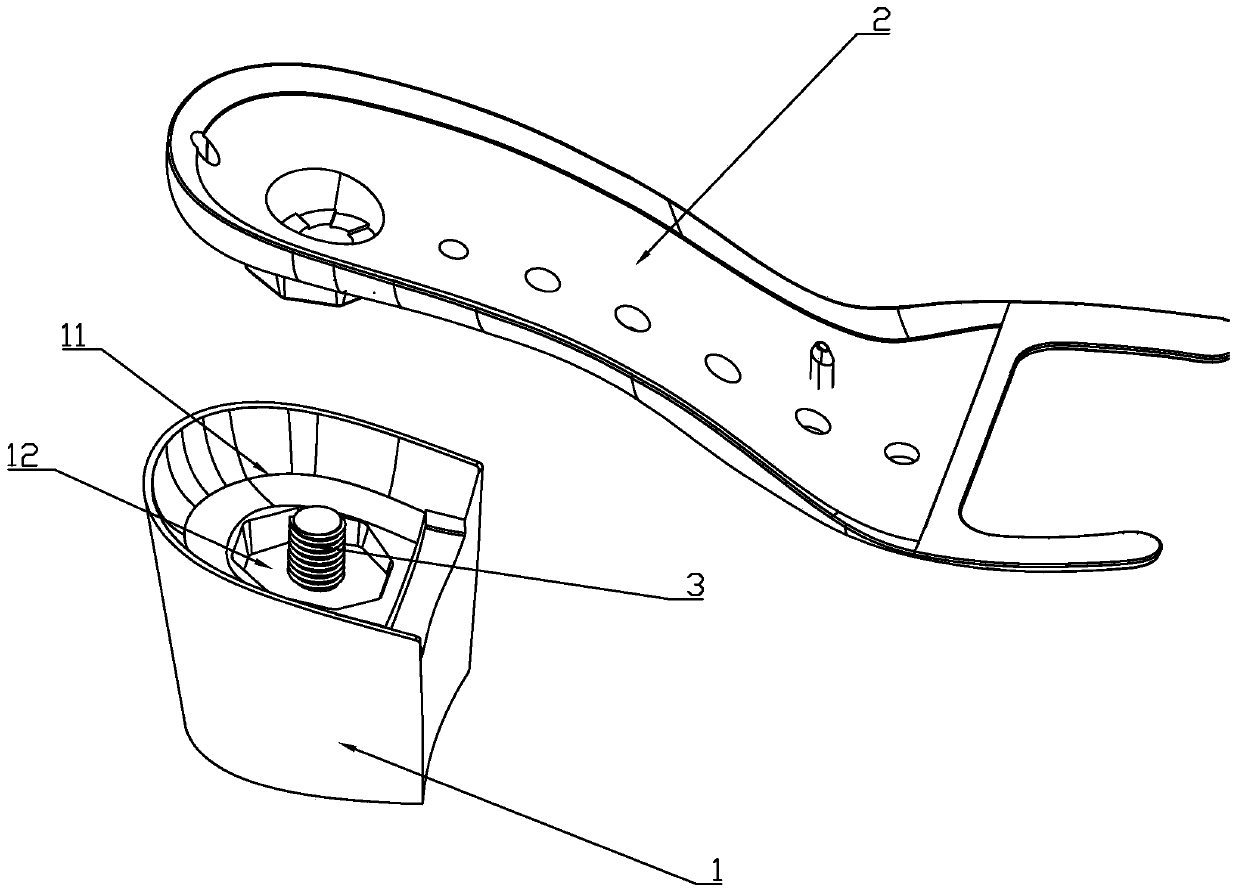

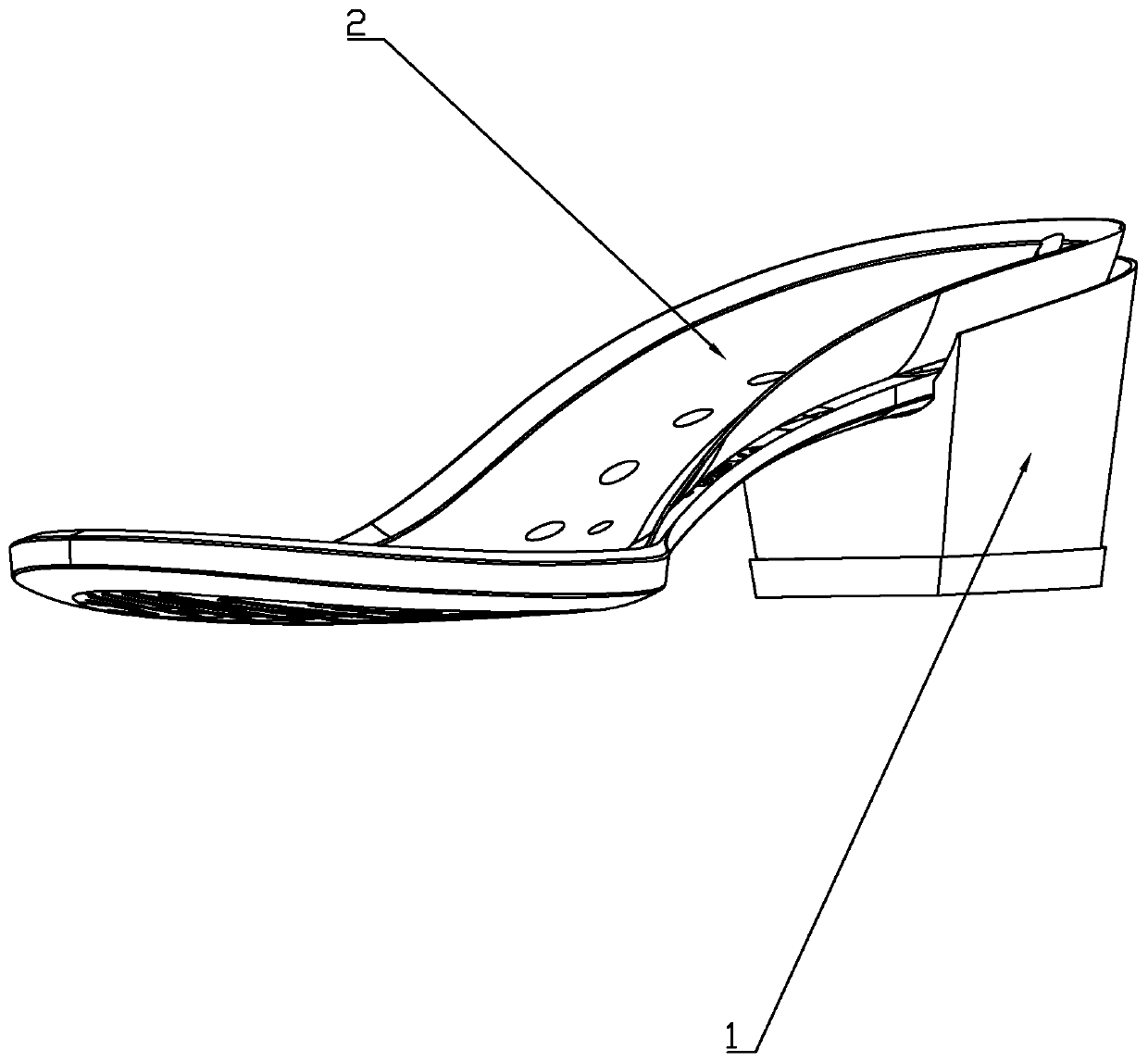

[0029] Example 1: by Figure 1 to Figure 6 It can be seen that the present invention discloses a high-heeled shoe heel, including a heel body, the heel body 1 is provided with a connecting column 3 for cooperating with the lumbar support 2, and the connecting column 3 and the heel body 1 are fixed as a whole . The waist support 2 is a part of the sole, which is used for mutual installation and cooperation with the heel to support and fix the heel, because the connecting column 3 and the heel body in the heel of the high-heeled shoe are used to cooperate and fasten with the waist support 2. 1 is integrally formed by injection molding, so the connection column 3 and the waist support 2 are tightly matched to realize the tight cooperation of the heel body 1 and the waist support 2, so there is no need to open a boring hole in the heel body 1 for installation and fastening. Therefore, there is no need to consider the wall thickness of the heel body 1 or the screw-in strength of t...

Embodiment 2

[0035] Example 2: by Figure 7 It can be seen that there is another solution in which the heel body 1 and the connecting column 3 are integrally formed. The connecting column 3 and the heel body 1 are both metal parts, and the connecting column 3 and the heel body 1 are integrally formed by die casting. The specific embodiment is to pour the molten metal into the mold with the shape of the heel body 1, pour the molten metal into the mold, and then directly die-cast it into the shape of the heel body 1, so that the heel body 1 and the connecting column 3 are integrally formed. , the molding method is convenient to manufacture, and the heel made of metal parts is relatively strong and not easy to be damaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com