Production method of environment-friendly plaster powder

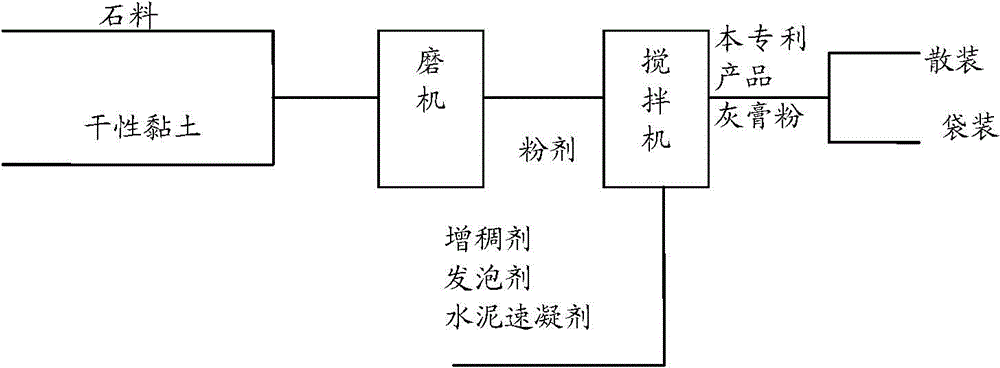

A production method and plaster technology, applied in the field of building materials, can solve the problems of poor seismic resistance, inconvenient construction, empty shell, etc., and achieve the effects of high safety, convenient transportation and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Based on the percentage of the total weight of the raw materials, 70% of the limestone with a Mohs hardness greater than 4 and 30% of the dry white mud clay with a water content of less than 5% are ground to 300 mesh with a Raymond machine, respectively. Mix evenly, add 200,000 viscosity hydroxypropyl methylcellulose (HPMC), the amount accounts for 0.005% of the total weight of limestone and dry white mud clay; add the mixture of sodium abietate and sodium lauryl sulfate, the amount accounts for limestone and 0.001% of the total weight of dry white mud clay, the mass ratio of sodium rosinate and sodium lauryl sulfate is 1:1; adding cement instant solvent aluminum titanate, the amount accounts for 1% of the total weight of limestone and dry white mud clay 0.001%, stir well, that is.

Embodiment 2

[0024] According to the percentage of the total weight of raw materials, 60% of shale with Mohs hardness greater than 3.5, 20% of dry common red mud clay with a water content of less than 5%, and 10% of coal ash were used respectively with mine Grind to 300 mesh and then mix evenly, add a mixture of 200,000 viscosity hydroxypropyl methylcellulose (HPMC) and polyacrylamide (PAM), the amount accounts for 0.007% of the total weight of shale and dry ordinary red mud clay %, the mass ratio of hydroxypropyl methylcellulose and polyacrylamide is 2:5; add a mixture of sodium abietate and sodium lauryl sulfate, and the amount accounts for 0.001 of the total weight of shale and dry common red mud clay %, the mass ratio of sodium rosinate and sodium lauryl sulfate is 1:1; add cement instant solvent aluminum titanate, the amount accounts for 0.001% of the total weight of shale and dry common red mud clay, and stir evenly to obtain .

Embodiment 3

[0026] According to the percentage of the total weight of raw materials, take 80% of the weathered stone with a Mohs hardness greater than 3.5 and 20% of the dry common red mud clay with a moisture content of less than 5%, and grind them to 300 mesh with a Raymond machine Mix evenly again, add a mixture of 200,000 viscosity hydroxypropyl methylcellulose (HPMC) and polyacrylamide (PAM), the consumption accounts for 0.007% of the total weight of weathered stone and dry common red mud clay, hydroxypropyl methylcellulose The mass ratio of base cellulose and polyacrylamide is 3:4; Add the mixture of sodium abietate and sodium lauryl sulfate, the consumption accounts for 0.001% of the total weight of weathered stone and dry common red mud clay, sodium abietate and The mass ratio of sodium lauryl sulfate is 1:1; adding cement instant solvent aluminum titanate in an amount of 0.001% of the total weight of weathered stone and dry ordinary red mud clay, stirring evenly, and the product i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com