Rivet type lining fluorine axial-flow pump

An axial flow pump and fluorine-lined technology, which is applied in the direction of non-variable pumps, non-volume pumps, and special fluid pumps, can solve problems such as loose screws, complicated processing technology, and reduced strength of the fluorine-lined layer of the pump body. Achieve the effects of improving service life, eliminating vacuum siphon, and increasing connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

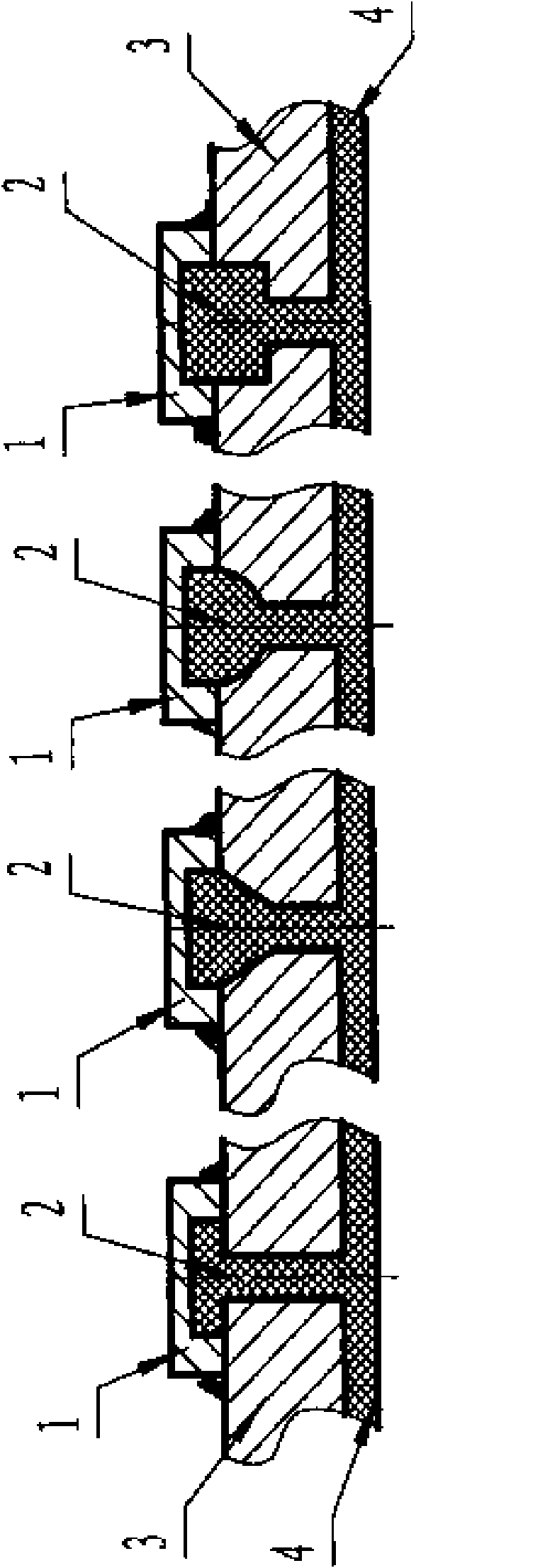

[0015] From figure 1 It can be seen from the figure that the rivet-type fluorine-lined axial flow pump includes a metal insert 3 and a fluorine-lined layer 4, and several through holes 2 are evenly distributed on the metal insert 3, and the outer side of the metal insert 3 Each through hole 2 is provided with a metal cap 1, the inner cavity cross-sectional area of the metal cap 1 is larger than the cross-sectional area of the through hole 2, and the fluorine-lined layer 4 passes through the inner cavity and the through hole of the metal cap 1 2 is riveted on the inner side of the metal insert 3; the cross section of the through hole 2 can be one of conical, semicircular or stepped; the through hole 2 is provided with threads.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com