Temperature and pressure monitoring cable with protection tube and manufacturing method thereof

A technology of temperature, pressure, and manufacturing method, which is applied in the directions of surveying, earth-moving, wellbore/well components, etc., can solve the problems of increasing construction difficulty, affecting the test success rate, affecting the coiled tubing strength, etc., and achieving the effect of improving the success rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1: Taking a temperature and pressure monitoring cable with a protective tube and its manufacturing method as an example, the present invention will be further described in detail.

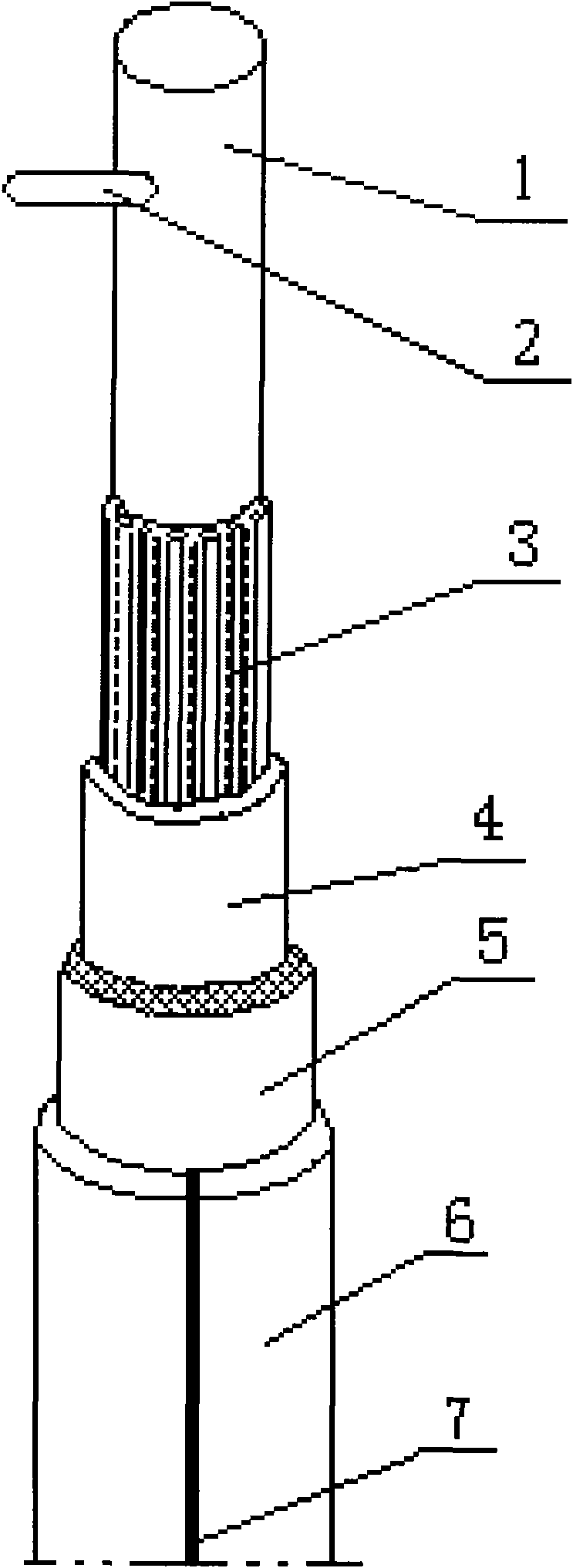

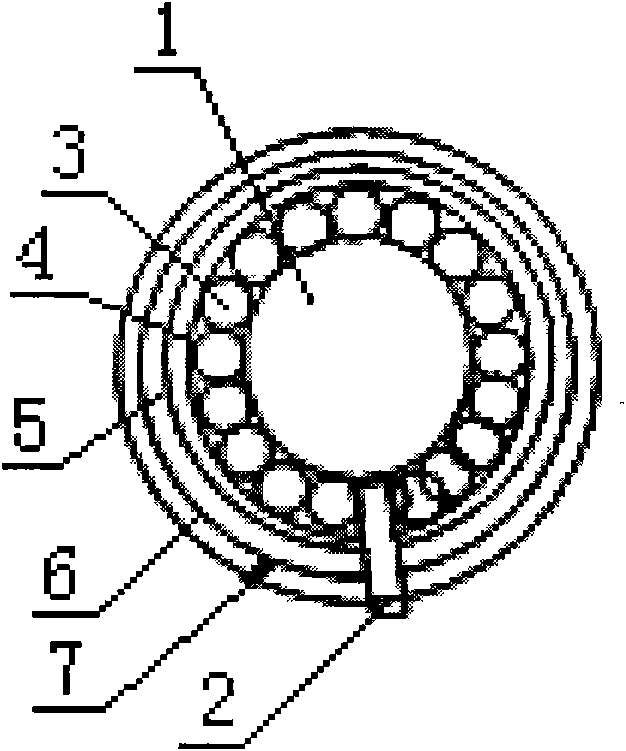

[0032] refer to figure 1 . The temperature and pressure monitoring cable with protective tube of the present invention is mainly composed of a cable bundle 1, a pressure measuring port (pressure guiding hole) 2, a steel wire 3, an iron armor layer 4, a filling layer 5 and a protective tube 6.

[0033] An oil well needs a temperature and pressure monitoring cable with a length of 1700m, and needs to monitor the formation pressure at three key points of the oil layer and the formation temperature at six key points. The pressure monitoring depths of the three points are 1200m, 1400m and 1700m respectively, and the temperature monitoring depths of the six points are 1200m, 1300m, 1400m, 1500m, 1600m and 1700m respectively.

[0034] Cable bundle 1 is composed of three pressure measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com