Prefabricated berthing component installation supporting structure and installation method

A technology for ship-retaining components and supporting structures is applied in the field of prefabricated ship-receiving components installation and support structures, which can solve the problems of troublesome construction of ship-receiving components and complicated supporting structures, and achieves simple and convenient pouring and molding, simple supporting structure, and reduced construction difficulty. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

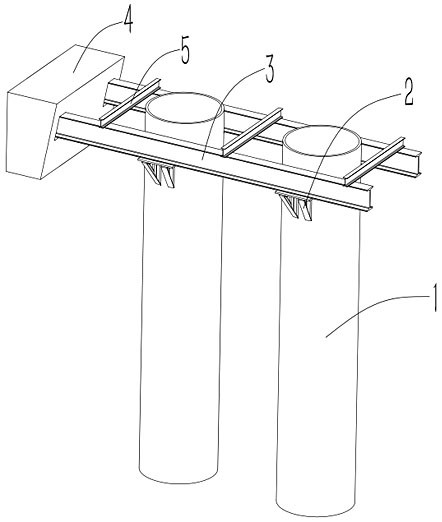

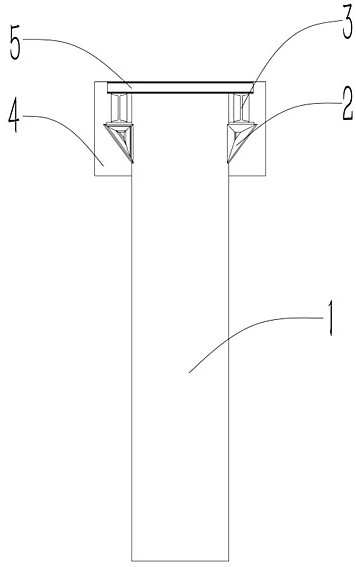

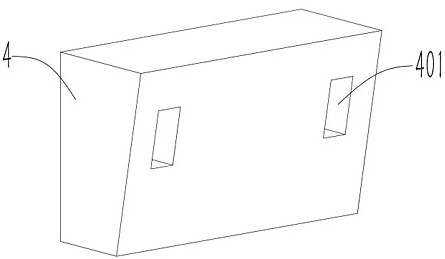

[0031] like Figure 1~8 As shown, a prefabricated ship berthing member installation support structure and installation method, including a ship berthing member 4 and a steel pipe pile 1, is characterized in that: the two sides of the end surface of the ship berthing member 4 are provided with grooves 401, the Both sides of the steel pipe pile 1 are fixed with a support frame 2, and an I-beam 3 is arranged on the support frame 2. One end of the I-beam 3 rests in the groove 401, and the other end of the I-beam 3 is provided with a balance fixing mechanism. With this structure, the groove 401 is reserved when pouring the berth member 4, and the pouring molding is simple and convenient, without affecting the strength of the berth member 4. The I-beam 3 is fixed on the support frame 2, and the end of the I-beam 3 is inserted into the In the groove 401, the ship berth member 4 is supported and fixed, and the stability of the I-beam 3 is ensured by a balanced fixing mechanism.

[00...

Embodiment 2

[0038] In conjunction with Example 1, such as Figure 1~8 As shown, the steel pipe pile 1 is constructed and installed on the bank; the fixed support frame 2 is installed on both sides of the steel pipe pile 1; the I-beam 3 and the beam 5 are installed on the support frame 2; The end of the I-beam 3, the end of the I-beam 3 leans against the groove 401 of the ship member 4; the bottom support system of the pile cap 6 is installed on the I-beam 3; the concrete for the pile cap 6 is poured, and the concrete is connected by Ship component 4; after the concrete is solidified, remove the I-beam 3, the beam 5 and the support frame 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com