Preparation method of corrosion prevention plating coating

A technology of anti-corrosion coating and aluminum coating, applied in the field of anti-corrosion, can solve the problems of not considering the protection treatment, reducing the hardness of materials, etc., and achieve the effect of no edge effect, good corrosion resistance and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is a method for preparing an aluminum coating, and its technical solution will be described in detail through 8 examples, see attached table 1.

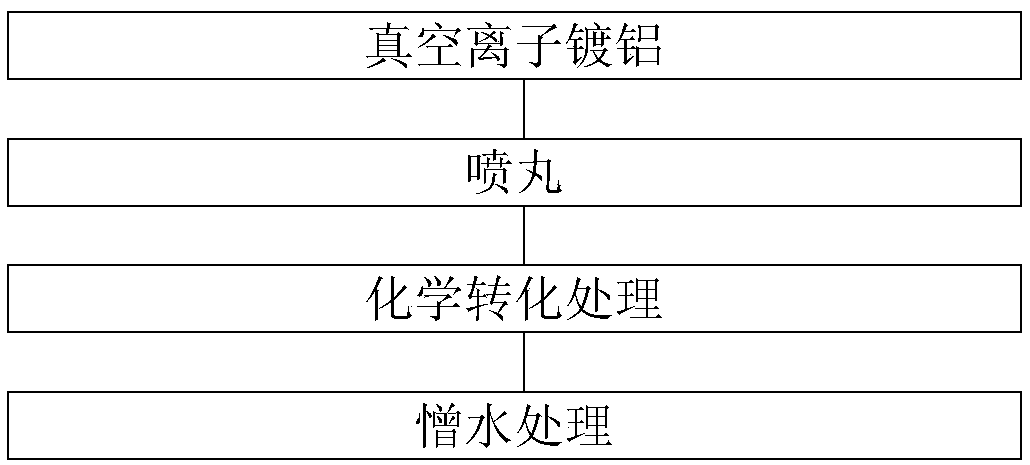

[0029] Concrete process of the present invention is:

[0030] Step 1, Vacuum ion plating aluminum: Using vacuum ion plating method, under the vacuum state of 1.0-1.5Pa, using evaporation-glow discharge, the evaporated metal aluminum atoms are ionized and bombarded and deposited on the parts under the action of an electric field. Aluminum coating is formed on the surface of the part.

[0031] The specific process parameters of the vacuum ion aluminum plating: the air pressure is 1.0-1.5Pa, the target current is 60-90A, the bias voltage is 30-100V, the temperature is 150-250°C, and the time is 2.5h.

[0032] Step 2, shot peening: Since there will be connected pores inside the ion-plated aluminum film, in order to obtain a non-porous aluminum coating on the surface of the part or test piece, glass beads or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com