Wind driven power generating system

A wind turbine, vertical axis technology, applied in the direction of wind turbine components, wind engines, wind engines consistent with the wind direction, etc., can solve problems such as inability to generate electricity, difficult to control, reverse rotation direction, etc., to prevent overload work , easy to lead out and maintain, prevent winding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Hereinafter, the present invention will be described in detail with reference to the drawings.

[0032] Repeated explanations are omitted for parts that are the same as the traditional ones.

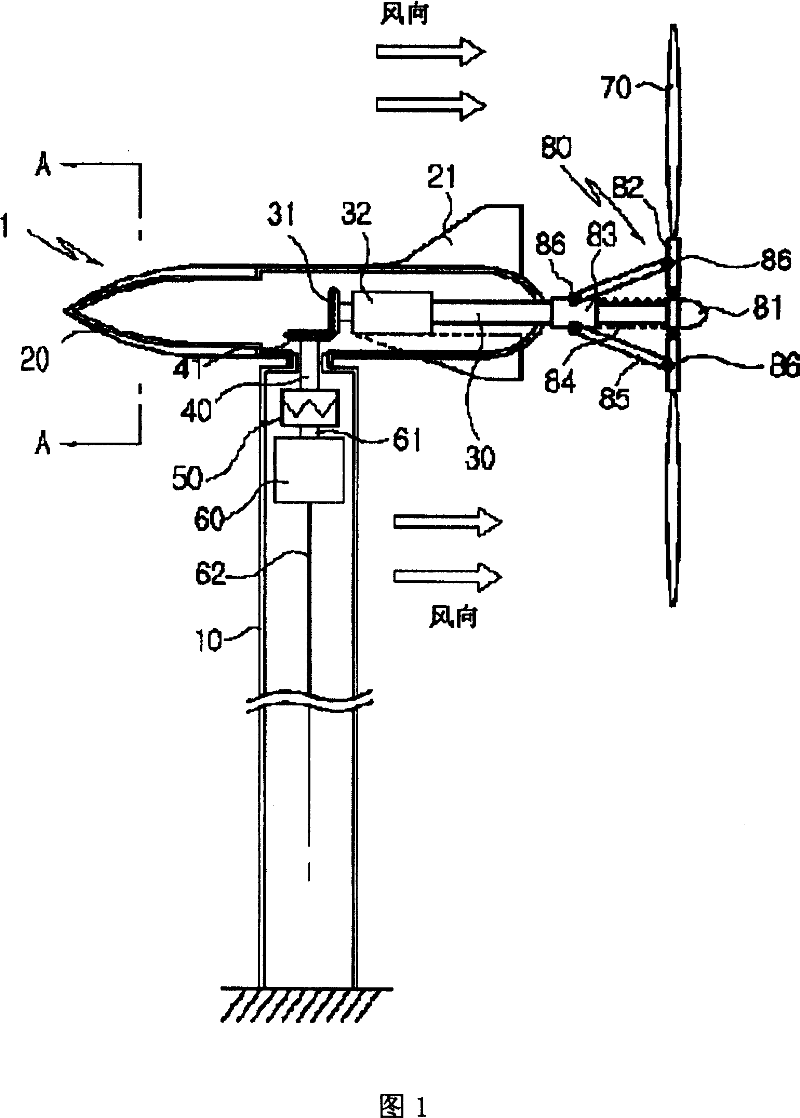

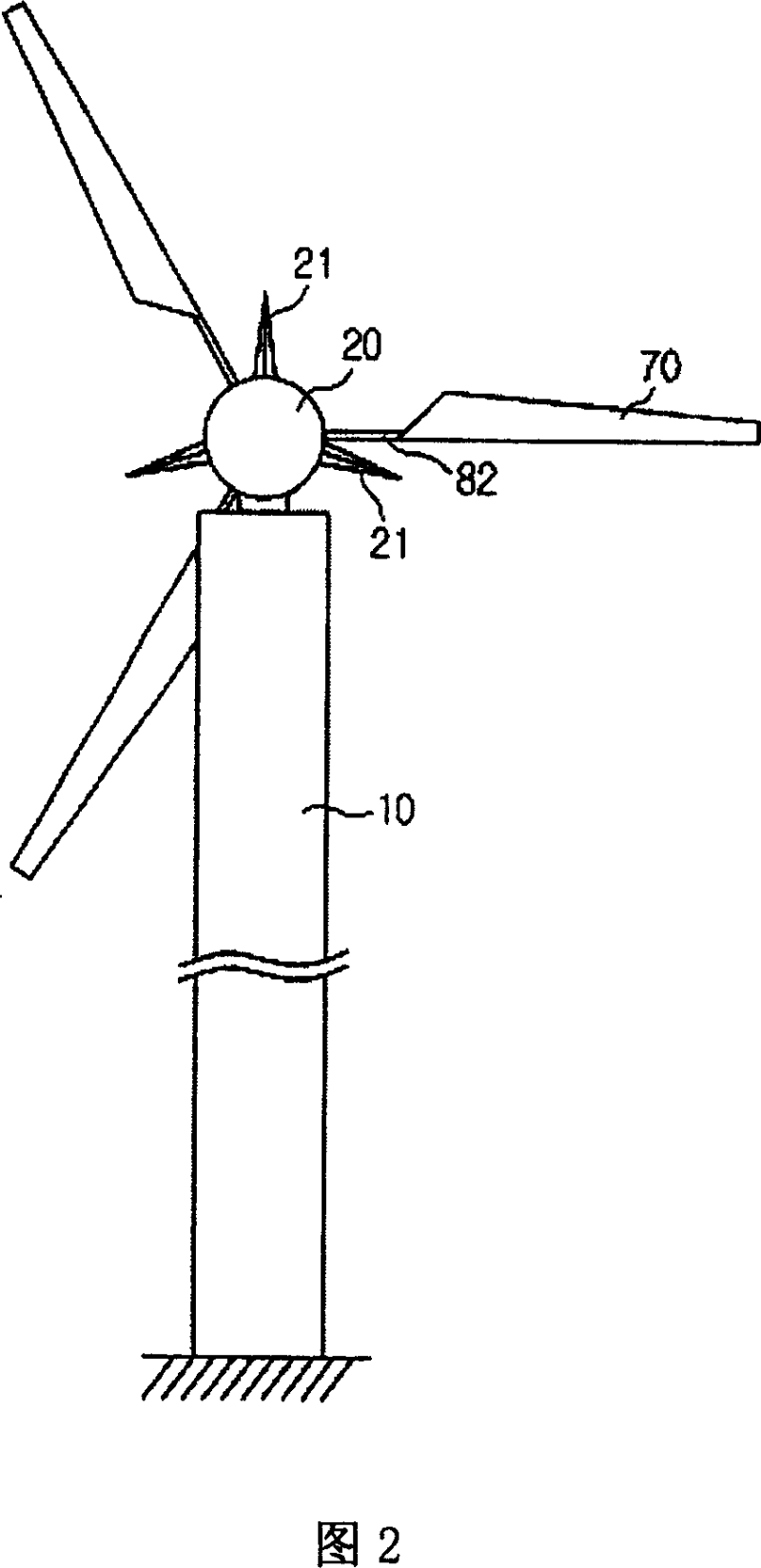

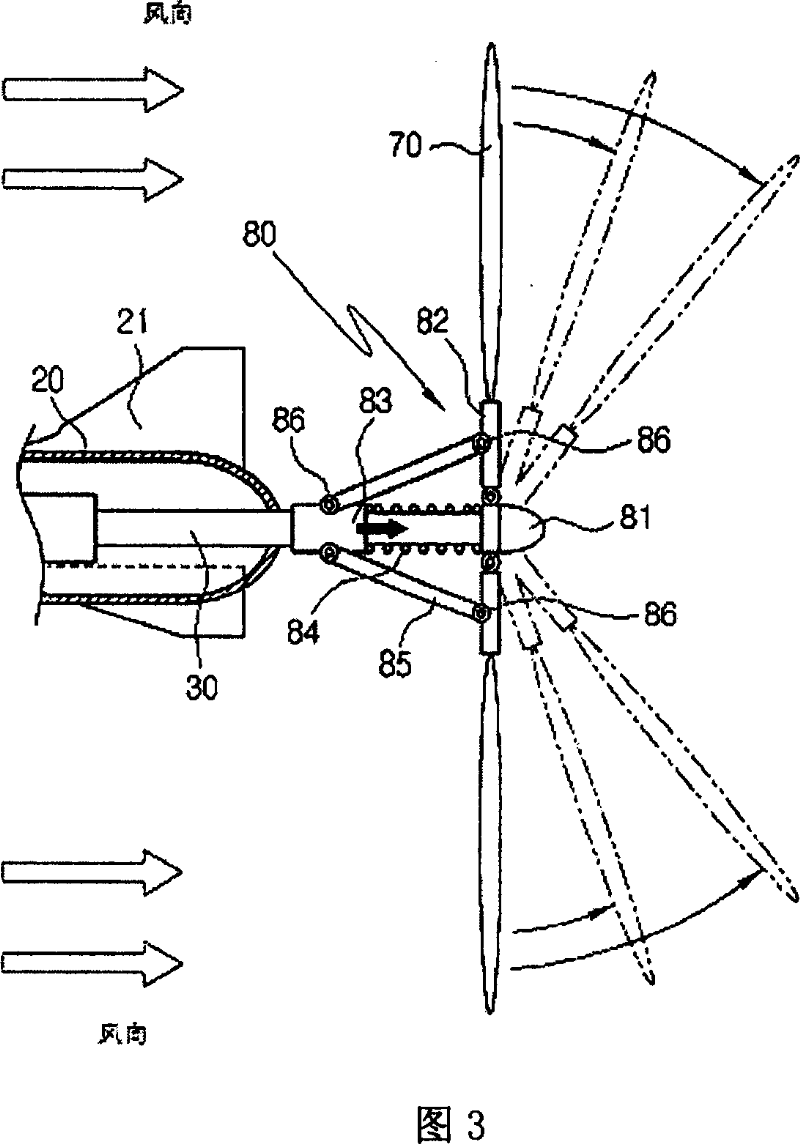

[0033] 1 is a sectional view of a wind generator according to the present invention, FIG. 2 is a front view of the wind generator according to the present invention, and FIG. 3 is a state diagram of variable blades in the wind generator according to the present invention.

[0034] As shown in the figure, according to the wind power generator 1 of the present invention, a rotatable streamlined movable body 20 is arranged on the upper end of a tower 10 at a certain height on the ground.

[0035] In order to reduce the weight, it is better for the above-mentioned movable body 20 to be hollow inside.

[0036] Then, three rudders 21 are radially formed on the outer surface of the movable body 20 .

[0037] Here, the rudder 21 is preferably formed toward the rear of the movable body 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com