Waterproof coiled material pre-paving and inverted sticking process

A waterproof membrane, pre-paved anti-adhesive technology, used in infrastructure engineering, protection devices, gaskets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

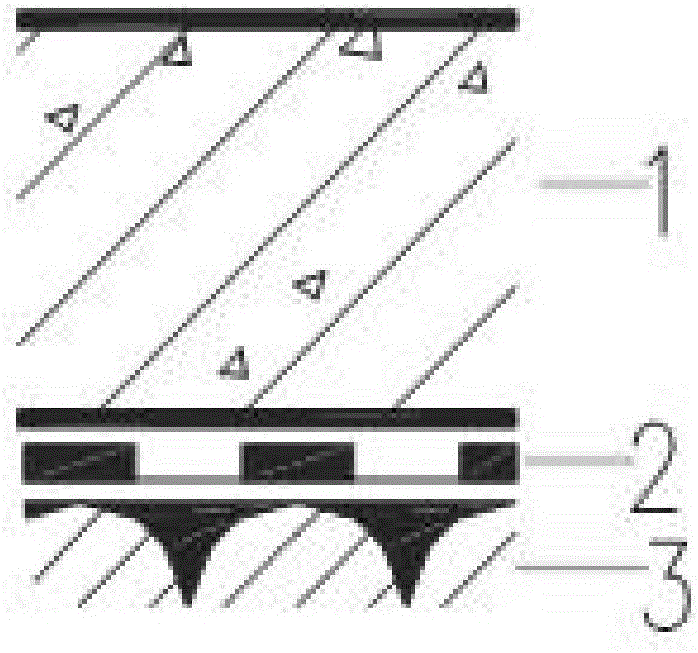

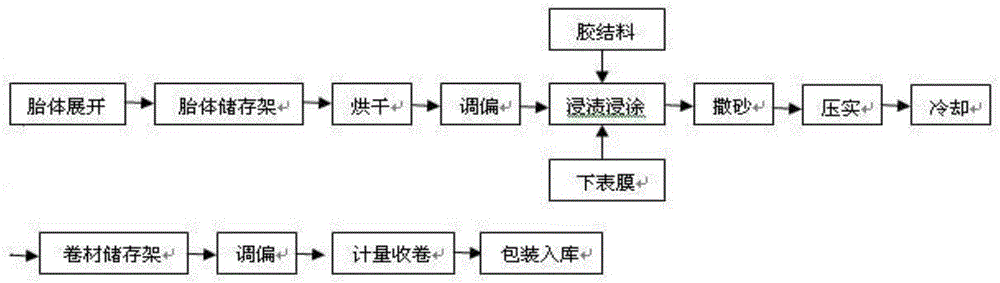

[0070] A lapping method introduced by the content of the manual, the material is waterproof roll material 2 with double lapping sides, the lapping width of the long side is 70mm, and the first lapping side is HDPE base film + isolation film + self-adhesive film + Isolation film, the second lap is HDPE base film + isolation film + self-adhesive film + reactive sand layer.

[0071] During construction, the isolation film on each side is torn off, the HDPE base film + self-adhesive film on the first lap of the first waterproof membrane is exposed and separated, and the HDPE bottom of the second lap on the second waterproof coil is separated. The membrane is separated from the self-adhesive film + reactive sand layer, and the HDPE bottom film of the second lap of the second waterproof roll is lapped on the HDPE bottom film of the first lap of the first waterproof roll of another roll At the same time, use a hot air welding machine to heat the lapped edges, and after the coiled mat...

Embodiment 2

[0074] A lapping method introduced by the contents of the manual, the material is a waterproof membrane 2 with a single lapping edge, the material should be a single lapping edge, and the lapping width is 70mm.

[0075] During construction, put the non-lap edge reaction sand layer of the coil upward, and cover the exposed HDPE film surface of the other coil, heat the lap edge with a hot air welding machine, and compact it with a pressure roller after the coil is slightly melted; When the short side is lapped, use a special tool to shovel off the self-adhesive film layer and reactive sand layer on the surface of the coiled material that will be on the bottom surface, and then cover another coiled material on the exposed HDPE film surface, and heat it with a hot air welding machine For the overlapping edge, after the coil is slightly melted, compact it with a pressure roller, and fill the gap with a pressure-sensitive hot melt adhesive that is heated immediately on site. The over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com