High-molecular self-adhesive film waterproof roll welding and lapping structure and construction method

A technology of self-adhesive film and waterproof membrane, which is applied in infrastructure engineering, protection devices, gaskets, etc., to make up for difficult application, increase reliability, and ensure the effect of lap jointing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

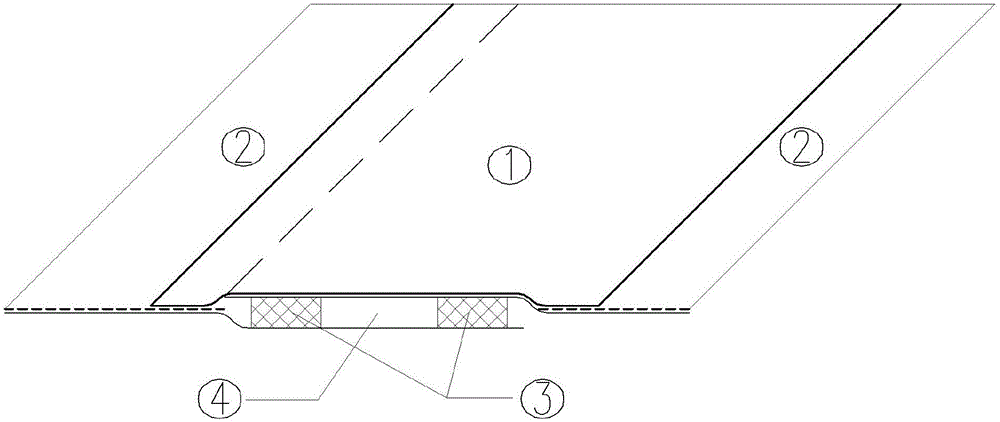

[0016] Concrete structure of the present invention sees figure 1 shown. Polymer self-adhesive film waterproof membrane welded lap joint structure, including: two coils (2), double weld seam (3) on the lap joint edge, reserved space between the double weld seam in the lap joint edge The cavity (4) and the sealing tape (1) covered and bonded above the overlapping portion; the roll material of the overlapping portion is a structure in which the adhesive layer is removed.

[0017] The construction method of polymer self-adhesive film waterproof membrane welding lap joint comprises the following steps:

[0018] Step 1: Put two polymer self-adhesive film waterproof rolls (2) in place;

[0019] Step 2: Use special equipment to remove the self-adhesive layer at the overlapping edge of the coil to expose the base plate;

[0020] Step 3: The double weld seams (3) on the overlapping edges of the two sheets of coils are lapped with the adhesive layer removed by a welding machine;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com