Cement concrete block for fixing the center frame of the sprinkler

A technology of center frame and sprinkler irrigation machine is applied in the field of cement concrete blocks to achieve the effects of firm fixation, low cost and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

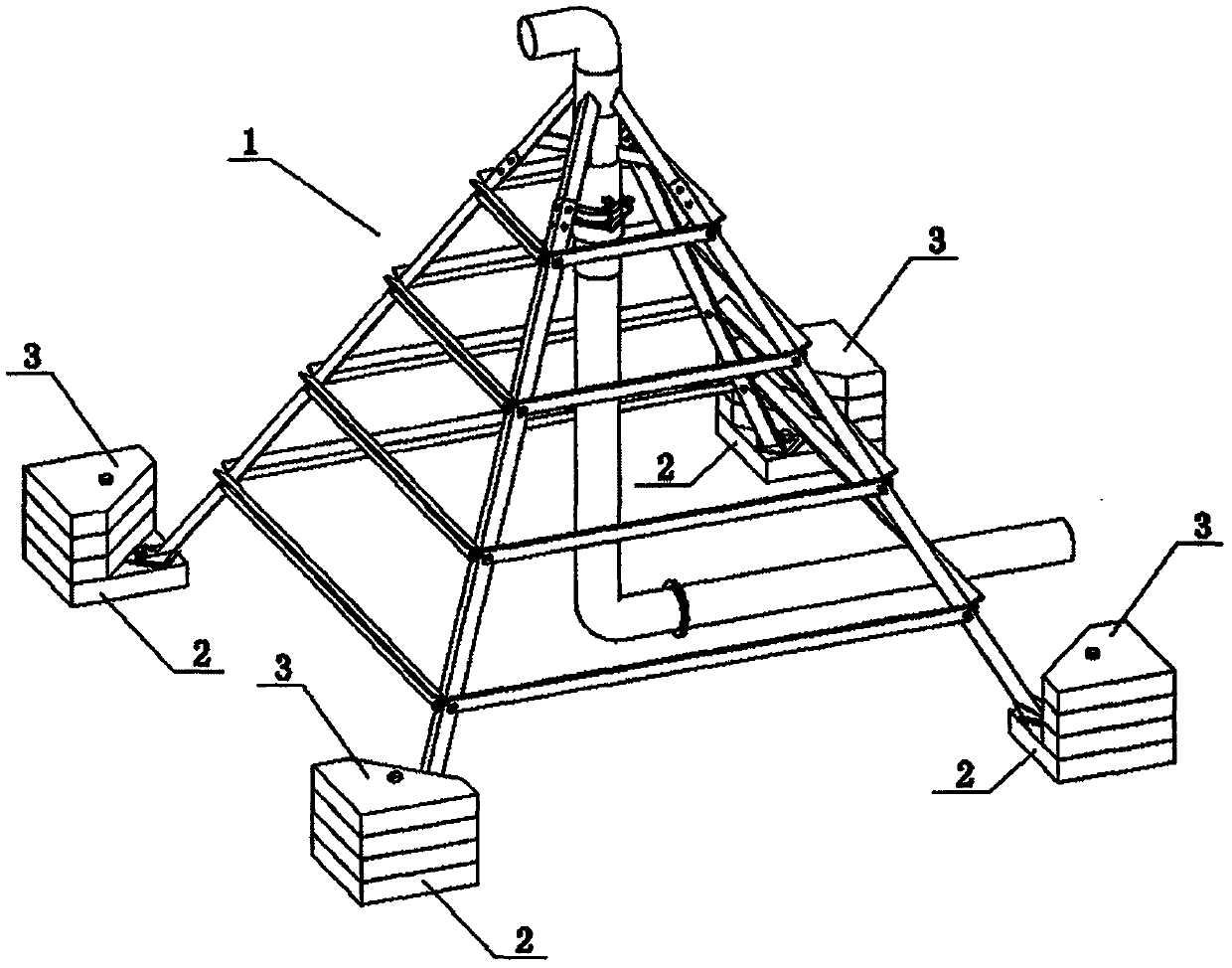

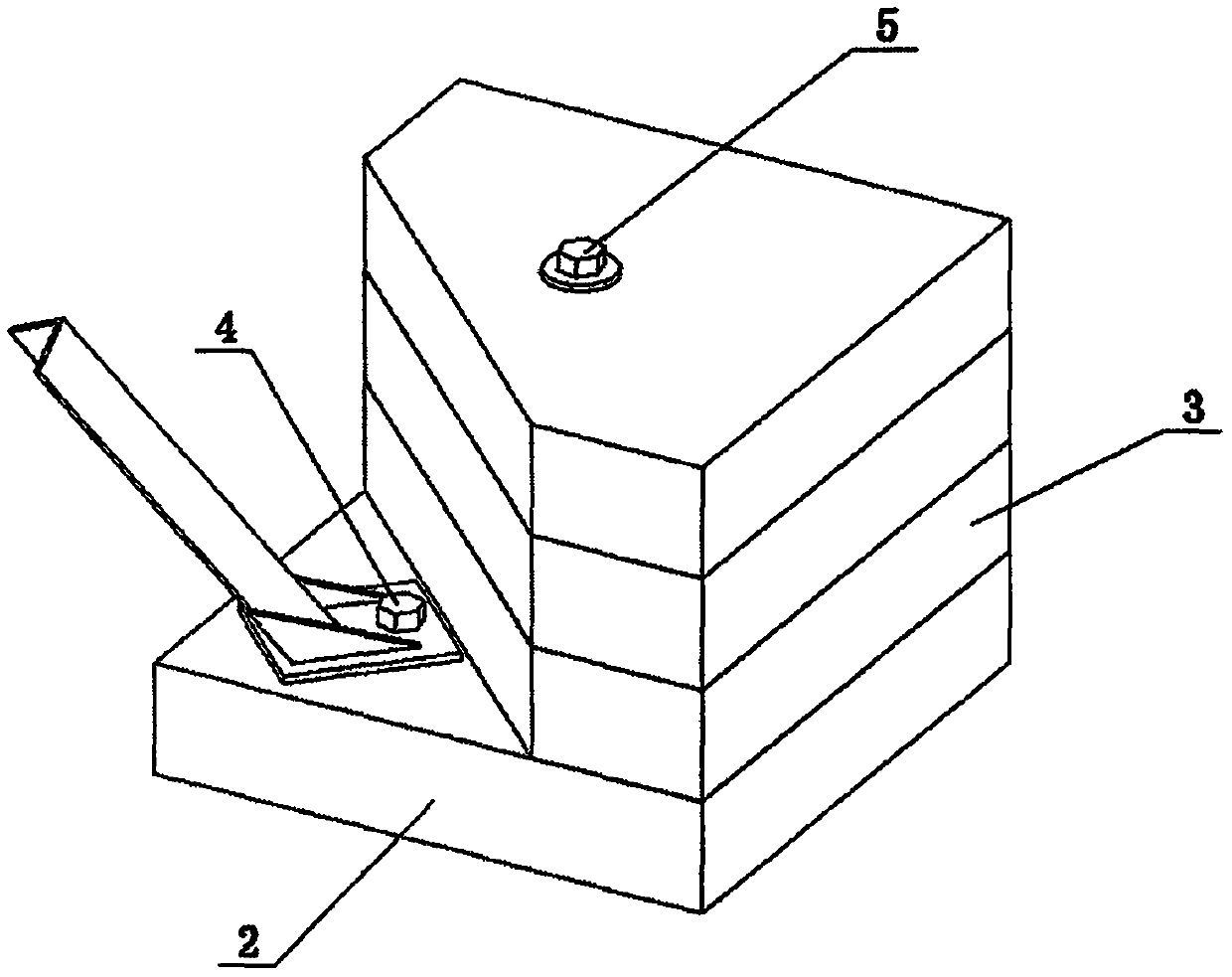

[0024] Such as Figure 1 to Figure 2 As shown, a cement concrete block for fixing the center frame of the sprinkler, which includes four bottom blocks 2, each bottom block 2 is equipped with three counterweight blocks 3, and four grounds connecting the center frame 1 and the bottom block 2 Foot bolts 4, four central bolts 5 connecting the bottom block 2 and its top superimposed counterweight 3.

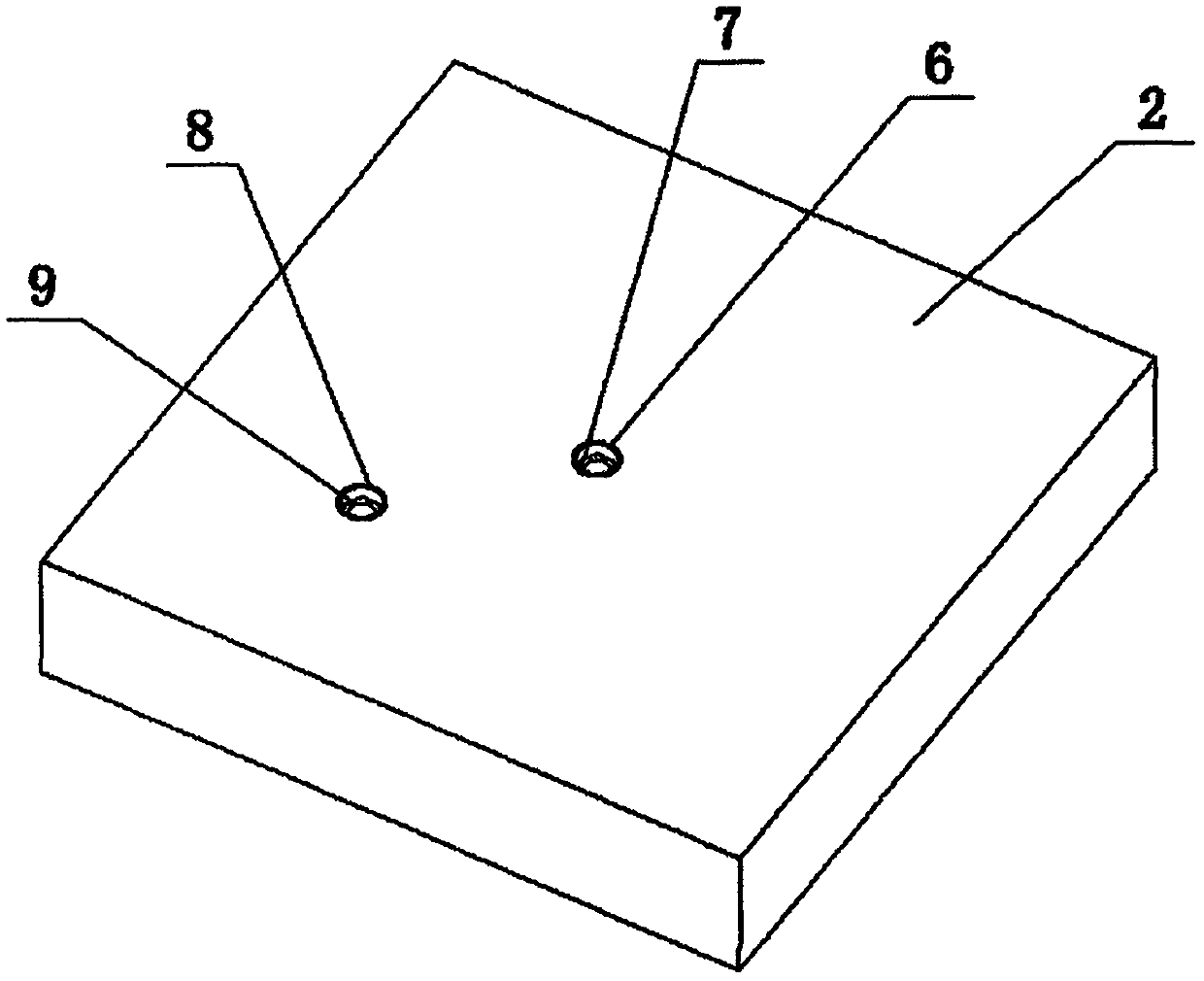

[0025] Such as Figure 3 to Figure 5 As shown, the bottom block 2 is a prefabricated block of cement with a steel cage inside, the center of the bottom block 2 is provided with a central casing 6 that runs through the upper and lower bottom surfaces, and a central nut 7 is fixed in the central casing 6; At the center of the line between the center and an angle on the bottom surface, there is an anchor sleeve 8 that runs through the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com