Small soft-slideway-type lifting machine

A soft slide type, hoisting machine technology, used in cranes, transportation and packaging, cable cranes, etc., can solve the problems of increasing the difficulty of cooperation between workers, reducing the safety factor, increasing the difficulty of operation, etc., and achieves a large bearing weight. , High security, and the effect of ensuring work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

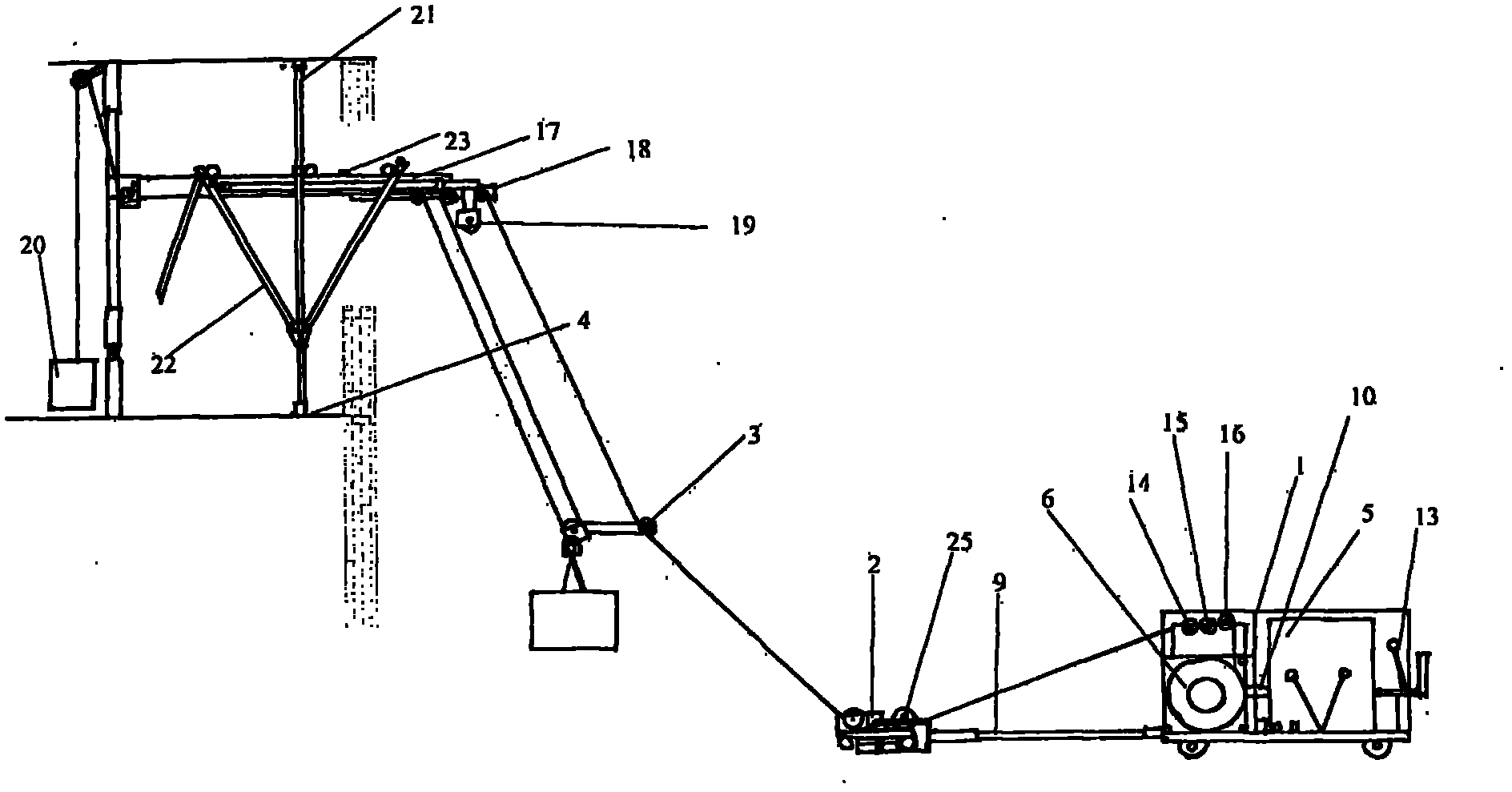

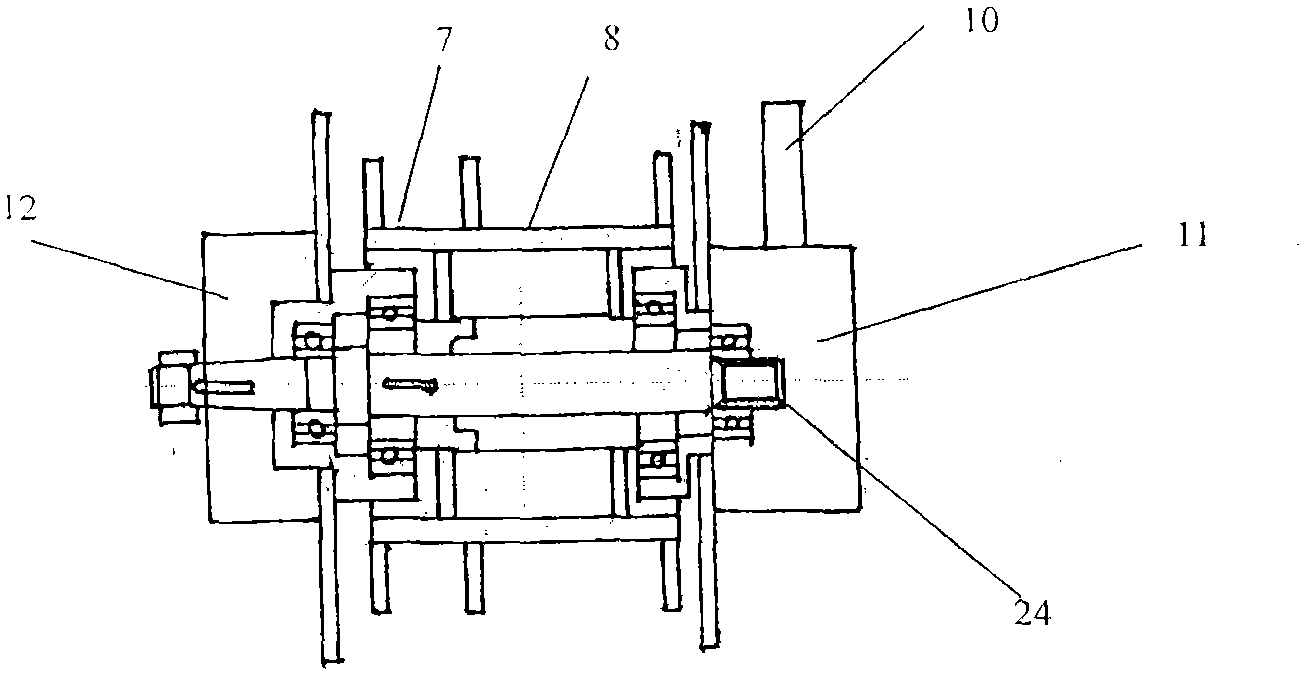

[0010] Such as figure 1 As can be seen from the three-dimensional cross-sectional structural schematic diagram of the present invention, the present invention includes four parts of main engine 1 (comprising gasoline engine 5, main roller rope winding system 6, etc.), direction pulley plate 2, soft slideway fixing device 3 and supporting part composition. The main roller rope winding system 6 is divided into a main rope winding chamber 7 and an auxiliary rope winding chamber 8, and the direction pulley plate 2 is connected with the main engine 1 through a steel pipe 9, so that the main engine can select a construction site within a 360-degree range.

[0011] The main engine 1 is powered by a water-cooled gasoline engine 5, drives a transmission 11 through a transmission shaft 10, and drives the main roller rope winding system 6. Brake 12 is equipped with respectively at two ends of main roller rope winding system 6, speed changer 11 and automatic lock device. The function of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com