Aqueous anticorrosive coating based on carbon nano composite material and preparation method thereof

A technology for composite materials and anti-corrosion coatings, applied in anti-corrosion coatings, polyester coatings, epoxy resin coatings, etc., to achieve uniform dispersion, strong hydrophilicity, compactness and improved integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

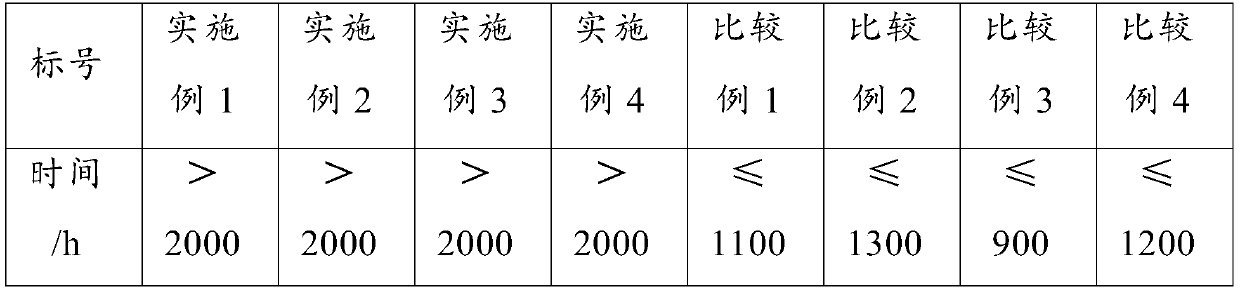

Examples

Embodiment 1

[0050] Preparation of modified graphene and modified carbon nanotubes:

[0051] Put graphene with a sheet diameter of 5 microns and 10 layers into a mixed solution of sulfuric acid and nitric acid, the ratio of sulfuric acid and nitric acid is 2:1, and ultrasonically disperse at 60°C for about 6 hours; then dilute with water and filter; Put the filtered solid matter into deionized water to obtain a mixture, add 5% sodium dodecylsulfonate of the total mass of the mixture, and ultrasonically disperse for 12 hours; filter, then add deionized water, and continue ultrasonically dispersing for 2 hours to obtain the improved permanent graphene.

[0052] Put carbon nanotubes with a diameter of 2 nanometers and a length of 50 microns into a mixed solution of sulfuric acid and nitric acid, the ratio of sulfuric acid and nitric acid is 2:1, and ultrasonically disperse at 60°C for about 6 hours; then dilute with water and filter; The solid obtained by filtration was placed in deionized w...

Embodiment 2

[0058] Preparation of modified graphene and modified carbon nanotubes:

[0059] Put graphene with a sheet diameter of 1 micron and 20 layers into a mixed solution of sulfuric acid and nitric acid, the ratio of sulfuric acid and nitric acid is 1:1, and ultrasonically disperse at 40°C for about 4.5 hours; then dilute with water and filter ;Put the filtered solid matter into deionized water to obtain a mixture, add 2% sodium dodecylsulfonate of the total mass of the mixture, and ultrasonically disperse for 15 hours; filter, then add deionized water, and continue ultrasonically dispersing for 1.5h. Obtain modified graphene.

[0060] Put carbon nanotubes with a diameter of 100 nanometers and a length of 5 microns into a mixed solution of sulfuric acid and nitric acid, the ratio of sulfuric acid and nitric acid is 3:1, and ultrasonically disperse at 80°C for about 7.5 hours; then dilute with water and filter; Put the filtered solid matter into deionized water to obtain a mixture, a...

Embodiment 3

[0067] Preparation of modified graphene and modified carbon nanotubes:

[0068] Put graphene with a sheet diameter of 50 microns and one layer into a mixed solution of sulfuric acid and nitric acid, the ratio of sulfuric acid and nitric acid is 3:1, and ultrasonically disperse at 80°C for about 7.5 hours; then dilute with water and filter ; put the filtered solid into deionized water to obtain a mixture, add 6% sodium dodecylbenzenesulfonate of the total mass of the mixture, and ultrasonically disperse for 9 h; filter, then add deionized water, and continue ultrasonically dispersing for 2.5 h, that is Modified graphene can be obtained.

[0069] Put carbon nanotubes with a diameter of 1 nanometer and a length of 200 microns into a mixed solution of sulfuric acid and nitric acid, the ratio of sulfuric acid and nitric acid is 1:1, and ultrasonically disperse at 40°C for about 4.5 hours; then dilute with water and filter; Put the filtered solid matter into deionized water to obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com