High manganese austenitic iron-based alloy containing boron

An iron-based alloy and austenitic technology, which is applied in the field of corrosion of boron-containing high-manganese austenitic iron-based alloys and its heat treatment, can solve the problems of increasing zinc consumption, reducing the operating rate of hot-dip galvanizing units, bending deformation of roll bodies, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

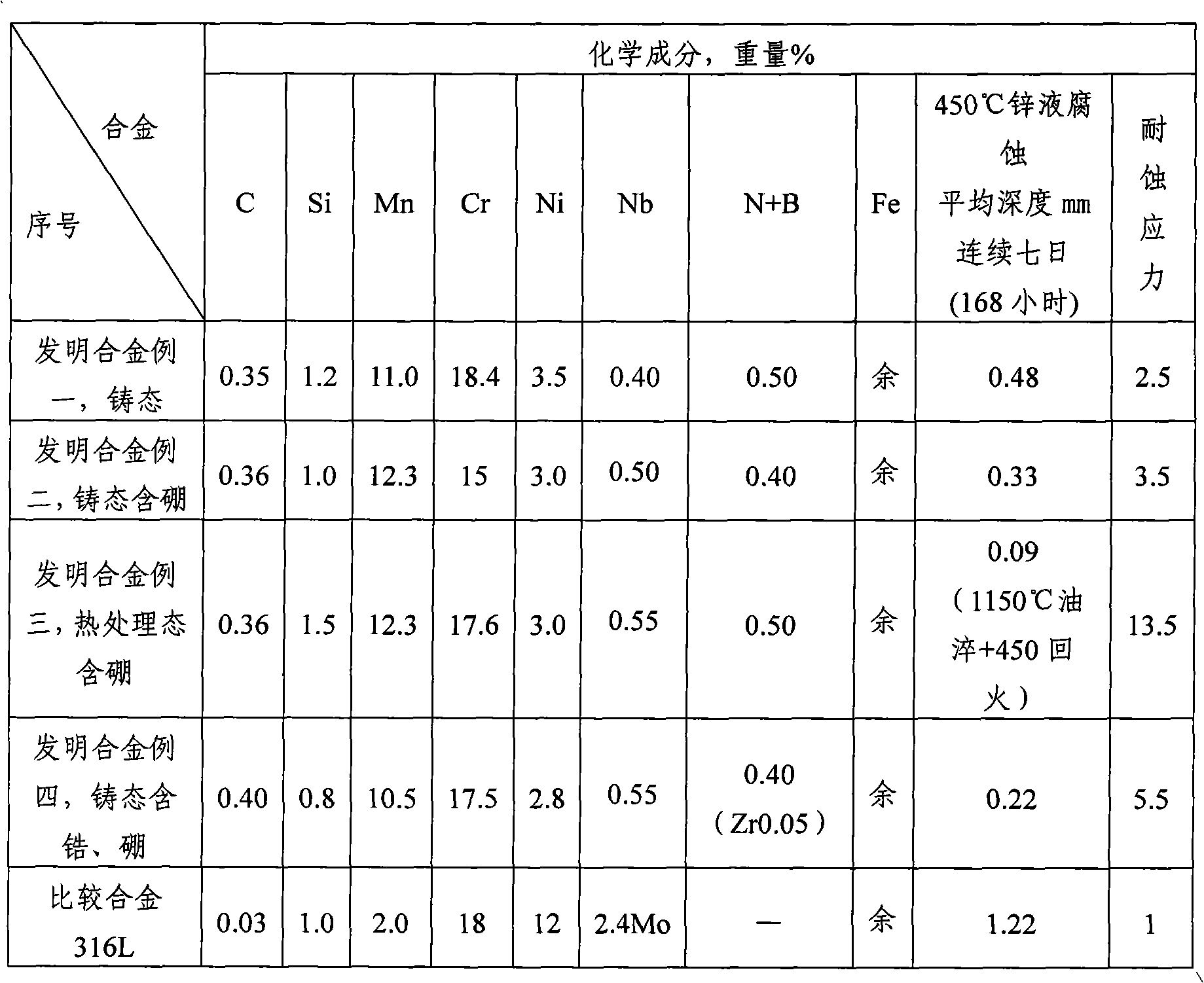

[0031] The alloy chemical composition listed in the table below is smelted and cast into a slab in a 10 kg vacuum induction furnace. Then cut and processed into impact, tensile and 15×10×5mm corrosion specimens. The corrosion test was carried out in the graphite crucible of the well-type resistance furnace. The liquid zinc is heated to 450°C, using a full immersion method. After a static corrosion test for seven consecutive days (168 hours), the average corrosion depth of the sample (ie, the average thickness loss of the sample) is measured.

[0032]

[0033] From the above table, it can be seen that the corrosion resistance of liquid zinc in alloy example 1 of the invention is 2.5 times that of 316L, and the corrosion resistance of liquid zinc in alloy example 2 of the invention is 3.5 times that of 316L cast alloy. The corrosion resistance to liquid zinc of Inventive Alloy Example 3 is 13.5 times that of 316L, and the corrosion resistance of Inventive Alloy Example 4 is 5.5 t...

Embodiment 2

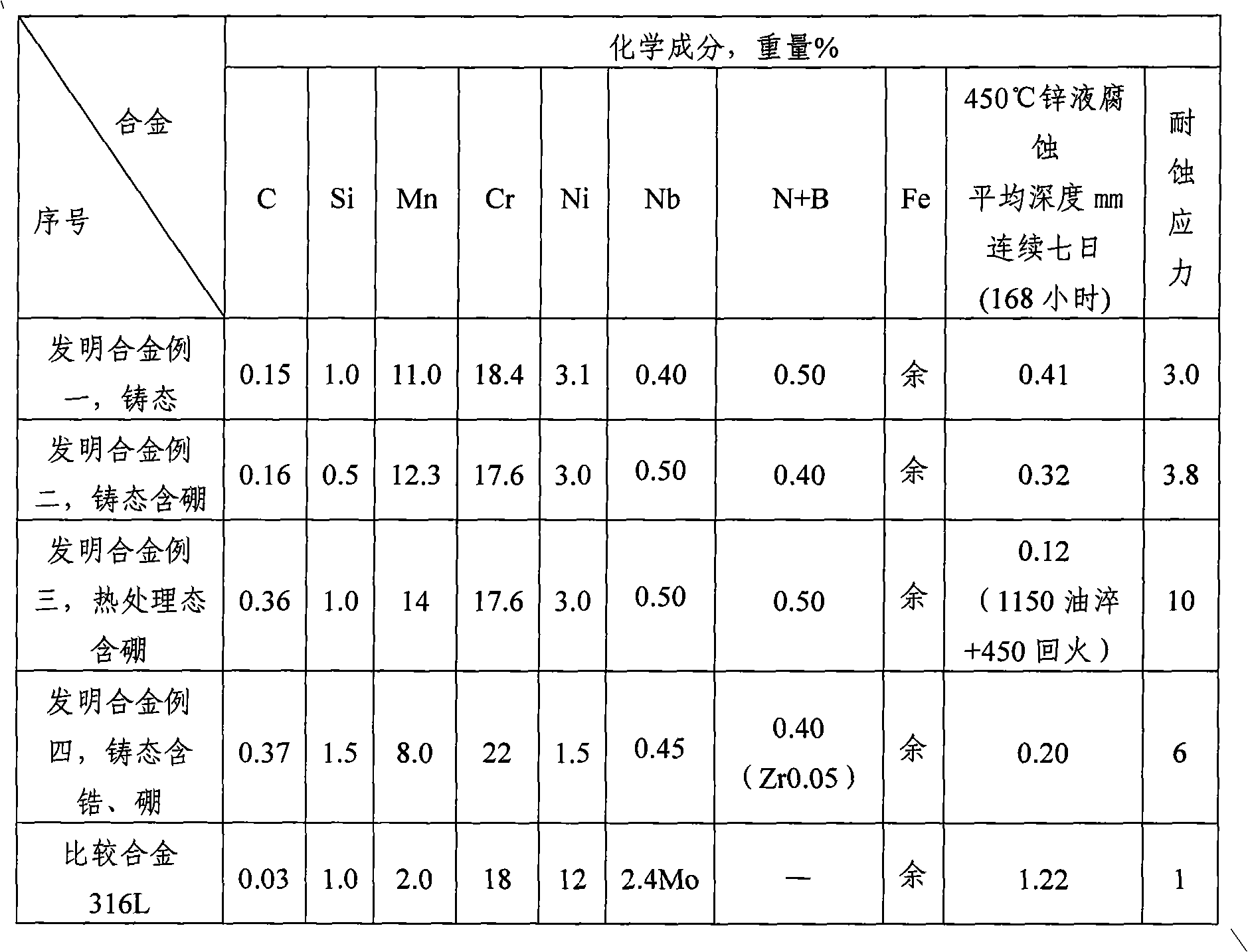

[0036] The alloy chemical composition listed in the table below is smelted and cast into a slab in a 10 kg vacuum induction furnace. Then cut and processed into impact, tensile and 15×10×5mm corrosion specimens. The corrosion test was carried out in the graphite crucible of the well-type resistance furnace. The liquid zinc is heated to 450°C, using a full immersion method. After a static corrosion test for seven consecutive days (168 hours), the average corrosion depth of the sample (ie, the average thickness loss of the sample) is measured.

[0037]

[0038] It can be seen from the above table that the corrosion resistance of liquid zinc in the first alloy of the invention is 3 times that of 316L, and the corrosion resistance of liquid zinc in the second alloy of the invention is 3.8 times that of the 316L cast alloy. Inventive alloy example 3 has a liquid zinc corrosion resistance 10 times that of 316L, and invention alloy example 4 has a liquid zinc corrosion resistance 6 ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com