Primer and topcoat syncretic zinc cold spray coating and preparation method thereof

A technology of cold-spraying zinc and coatings, which is applied in the direction of anti-corrosion coatings, rosin coatings, polyamide coatings, etc., which can solve the problems of not being able to adapt to harsh use environments and achieve a beautiful coating surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

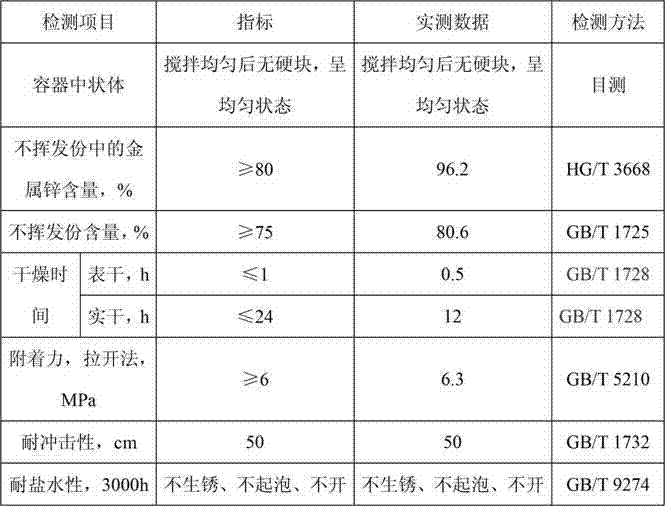

Examples

Embodiment 1

[0069] A cold spray zinc coating with a bottom surface is composed of the following components: thermoplastic solid acrylic resin B-66 (acid value 0.2mgKOH) 25kg; zinc powder 770kg; polyamide wax ULTRA2kg; nano silica solution VK-S01Y25kg ; Solvent PMA178kg.

[0070] The preparation method of the cold spray zinc coating:

[0071] 1. First add 100kg solvent PMA to the reactor;

[0072] 2. Start the disperser to 400 rpm, add 25kg of thermoplastic solid acrylic resin B-66, and dissolve to a transparent state;

[0073] 3. Slowly add 770kg zinc powder, and increase the speed of the disperser to 1200 revolutions per minute until the paint fineness is less than 40 microns;

[0074] 4. When the paint temperature naturally rises to 50-60 degrees, the speed of the disperser is reduced to 800 rpm, add 2kg of polyamide wax ULTRA, and stir for 30 minutes;

[0075] 5. Add the remaining 78kg solvent PMA and stir for 15 minutes;

[0076] 6. The speed of the disperser is reduced to 500 revolutions per mi...

Embodiment 2

[0081] A cold-sprayed zinc coating with one bottom surface is composed of the following components: thermoplastic solid polycarbonate resin (acid value 0.8mgKOH) 10kg; zinc powder (purity ≥99.5%, particle size 20-30μm) 900kg; poly Olefin wax 1kg; nano silica solution (particle size 10-30nm, concentration 10wt%) 10kg; solvent ethylene glycol butyl ether acetate 79kg.

[0082] The preparation method of the cold spray zinc coating:

[0083] 1. First add 39kg of ethylene glycol butyl ether acetate into the reactor;

[0084] 2. Start the disperser to 200 rpm, add the thermoplastic solid polycarbonate resin, and dissolve it to a transparent state;

[0085] 3. Add zinc powder slowly and increase the speed of the disperser to 1300 revolutions per minute until the paint fineness is less than 50 microns;

[0086] 4. When the paint temperature naturally rises to 45-60 degrees, the speed of the disperser is reduced to 850 revolutions per minute, polyolefin wax is added, and stirred for 30 minutes;...

Embodiment 3

[0090] A cold-sprayed zinc coating with one bottom surface is composed of the following components: thermoplastic polymer modified rosin resin (acid value 0.3mgKOH) 100kg; zinc powder (particle size 2-20μm, purity ≥99.9%) 750kg; modification Hydrogenated castor oil 10kg; nano silica solution (particle size 20-50nm, concentration 30wt%) 100kg; solvent glycol ethyl ether acetate 40kg.

[0091] The preparation method of the cold spray zinc coating:

[0092] 1. First add 67kg of ethylene glycol ethyl ether acetate into the reactor;

[0093] 2. Start the disperser to 500 rpm, add the thermoplastic polymer modified rosin resin, and dissolve it to a transparent state;

[0094] 3. Add zinc powder slowly and increase the speed of the disperser to 1000 revolutions per minute until the paint fineness is less than 40 microns;

[0095] 4. When the paint temperature naturally rises to 55-70 degrees, the speed of the disperser drops to 550 rpm, add modified hydrogenated castor oil, and stir for 30 mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com