Two-component epoxy organic anticorrosive paint and preparing method and using method thereof

An anti-corrosion coating, epoxy technology, applied in the field of coatings, to achieve good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

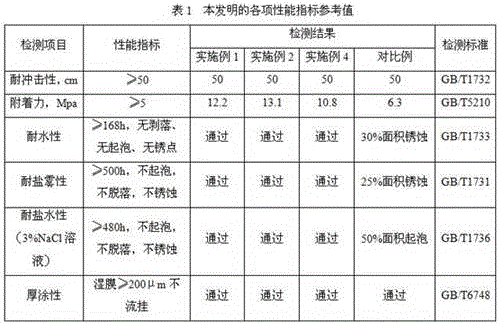

Examples

Embodiment 1

[0037] A two-component epoxy organic anti-corrosion coating, including component A and component B;

[0038] Component A is made of the following raw materials in weight percentage: 33-43 parts of epoxy silicone resin, 27-35 parts of epoxy resin, 4-7 parts of glass flakes, 13-17 parts of pigment, 4-7 parts of filler, auxiliary 1.3-2.2 parts of agent, 2-4 parts of diluent;

[0039] Component B is made of the following raw materials in weight percentage: 35-50 parts of polyamide curing agent, 13-17 parts of pigment, 4-7 parts of filler, 0.7-1.2 parts of anti-settling agent, and 40-60 parts of solvent;

[0040] The mass ratio of component A to component B is 10: (1-1.2).

[0041] The epoxy resin is bisphenol A solid epoxy resin.

[0042] The glass flakes are glass flakes treated with a silane coupling agent, and the particle size is 200-300 mesh.

[0043] The pigment is one or more of phosphorus zinc white, epoxy iron red, titanium dioxide, zinc phosphate, and N330 carbon blac...

Embodiment 2

[0053] A two-component epoxy organic anti-corrosion coating, including component A and component B;

[0054] Component A is made of the following raw materials in weight percentage: 33g of epoxy silicone resin, 27g of epoxy resin, 4g of glass flakes, 13g of pigment, 4g of filler, 1.3g of additive, and 2g of diluent;

[0055] Component B is made of the following raw materials in weight percentage: polyamide curing agent 35 g, pigment 13 g, filler 4 g, anti-settling agent 0.7 g, solvent 40 g;

[0056] The mass ratio of component A to component B is 10:1.

[0057] The epoxy resin is bisphenol A solid epoxy resin.

[0058] The glass flakes are glass flakes treated with a silane coupling agent, and the particle size is 200 mesh.

[0059] The pigment is phosphor zinc white.

[0060] The filler is a mixture of calcium carbonate and 1000 mesh talcum powder, and the mass ratio of talc powder to calcium carbonate is 4:3.

[0061] The additive is a mixture of pigment affinity group pol...

Embodiment 3

[0069] A two-component epoxy organic anti-corrosion coating, including component A and component B;

[0070] Component A is made of the following raw materials in weight percentage: 34g of epoxy silicone resin, 28g of epoxy resin, 4.4g of glass flakes, 13.4g of pigment, 4.4g of filler, 1.4g of additive, and 2.2g of diluent;

[0071] Component B is made of the following raw materials in weight percentage: polyamide curing agent 36 g, pigment 13.4 g, filler 4.4 g, anti-settling agent 0.75 g, solvent 42 g;

[0072] The mass ratio of component A to component B is 10:1.02.

[0073] The glass flakes are glass flakes treated with a silane coupling agent, and the particle size is 210 mesh.

[0074] The pigment is epoxy iron red.

[0075] The filler is a mixture of calcium carbonate and 1025 mesh talcum powder, and the mass ratio of talc powder to calcium carbonate is 4:3.

[0076] The additive is a mixture of pigment affinity group polymer copolymer dispersant, 606 defoamer, anti-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com