Material used in offshore wind power equipment, and workpiece manufacturing process

A technology for offshore wind power and wind power equipment, which is used in manufacturing tools, heat treatment equipment, furnace types, etc., and can solve problems such as poor corrosion resistance, poor corrosion resistance of Mn elements, and negative effects of corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

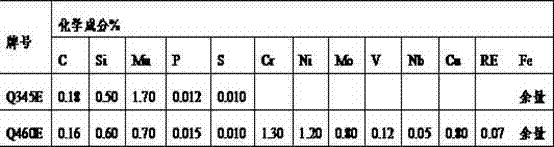

[0063] The comparison of the chemical composition and mechanical properties between the existing Q345E grade and the material (Q460E new grade) low-alloy steel used in the present invention for offshore wind power equipment is shown in Table 1 and Table 2:

[0064] Table 1 Chemical composition wt%

[0065]

[0066] Table 2 Mechanical properties (thickness 100~150mm)

[0067]

[0068] 1. The production process is as follows:

[0069] High-quality molten iron, KR molten iron pretreatment, 120-ton top-bottom composite blowing converter, argon blowing treatment, LF furnace refining, VD vacuum degassing treatment, continuous casting round billet (φ600~800mm), stack cooling, sawing and blanking, billet heating , Free forging, punching, precision pressing, heat treatment, machining, flaw detection, inspection, packaging and storage.

[0070] 2. Preparation steps

[0071] 1) KR hot metal pretreatment

[0072] When the hot metal arrives at the station, the slag should be ...

Embodiment 2

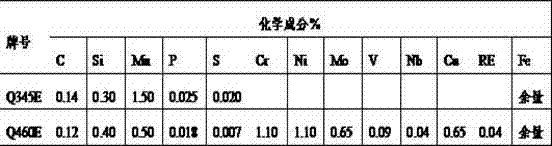

[0097] Now compare the actual chemical composition and mechanical properties of the Q345E grade with the material (Q460E new grade) used in offshore wind power equipment according to the present invention, see Table 3 and Table 4.

[0098] Table 3 Chemical composition wt%

[0099]

[0100] Table 4 mechanical properties (thickness 100~150mm)

[0101] 1,

[0102] 2, the production process is the same as in Example 1;

[0103] 3. Preparation steps

[0104] Preparation steps 1) to 12) are the same as in Example 1; the difference is that the chemical composition of the material (Q460E) used for offshore wind power equipment is controlled within the middle limit range, especially the oxygen content in the steel is controlled below 2.5ppm, and the sulfur ≤ 0.007% , rare earth ≥ 0.04%, so that the RE / S mass ratio is > 5 times, and the steel contains 0.04wt% niobium;

Embodiment 3

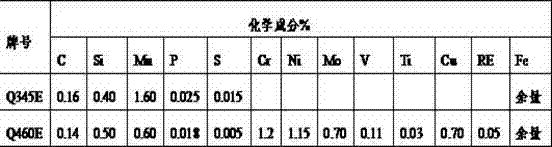

[0106] Now compare the actual chemical composition and mechanical properties of Q345E with the material (Q460E new grade) used in offshore wind power equipment according to the present invention, see Table 5 and Table 6

[0107] Table 5 Chemical composition wt%

[0108]

[0109] Table 6 mechanical properties (thickness 100 ~ 150mm)

[0110]

[0111] 1. The production process is the same as in Example 1.

[0112] 2. Preparation steps 1) to 12) are the same as in Example 1, except that the chemical composition of the material (Q460E new brand) used for offshore wind power equipment is controlled within the upper limit range, especially the oxygen content in the steel is controlled at 2.0ppm , sulfur ≤ 0.005%, rare earth ≥ 0.05%, and the steel contains 0.03wt% titanium;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com