Anti-corrosion carbon nanotube/silane composite super-hydrophobic coating and preparation method

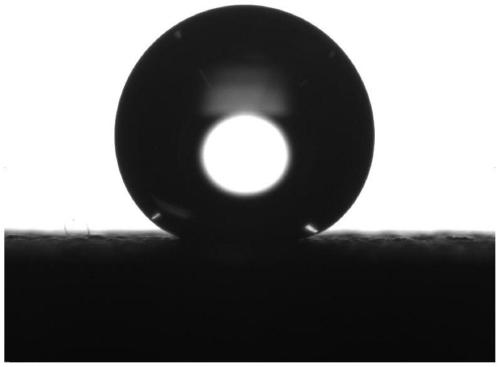

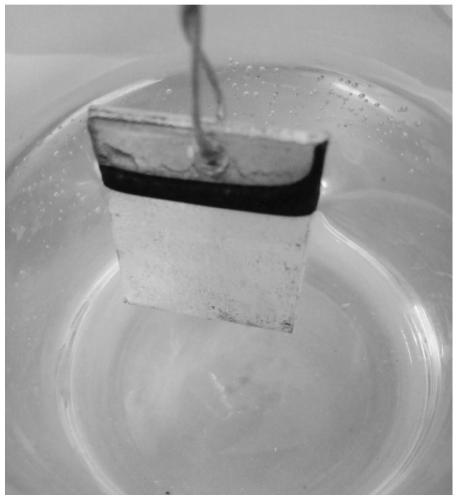

A super-hydrophobic coating, carbon nanotube technology, applied in coatings, metal material coating processes, devices for coating liquid on surfaces, etc., can solve the problem of poor chromium-free passivation protection performance, endangering personal safety, corrosion resistance It can improve mechanical stability and wear resistance and save resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A kind of preparation method of anticorrosion carbon nanotube / silane composite superhydrophobic coating of the present invention, comprises the following steps:

[0034] 1) Preparation of silane treatment solution: Add 4% to 5% (v / v) of silane coupling agent dropwise to deionized water (DI) / absolute ethanol (AE) mixed solution (DI:AE (v / v) v)=5~6:90), the mixed solution is placed on a magnetic stirrer and stirred at a rate of 600~1000rpm for 30~60min, and the pH value is adjusted to 5 by using 0.05~1mol / L glacial acetic acid, and then placed in Perform hydrolysis at room temperature for 3 to 6 days to obtain silane treatment solution;

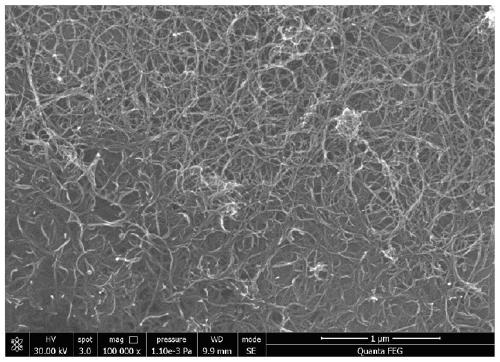

[0035] 2) Preparation of multi-walled carbon nanotubes (MWCNTs) loaded with corrosion inhibitor: First, the purified MWCNTs were ultrasonically dispersed in a mixed solution of concentrated sulfuric acid (98%) / concentrated nitric acid with a volume ratio of 3:1, and ultrasonically dispersed at 140°C. Disperse for 3 hours, then wash with...

Embodiment 1

[0041] Prepared as described above,

[0042] To prepare vinyltriethoxysilane treatment solution, add vinyltriethoxysilane coupling agent 4% (v / v) dropwise to deionized water (DI) / absolute ethanol (AE) mixed solution ( DI:AE(v / v)=6:90), wherein the volume ratio of the vinyltriethoxysilane coupling agent: the mixed solution of deionized water and absolute ethanol is 4%; the mixed solution is placed under magnetic force Stir on the stirrer at 800rpm for 50min, adjust the pH value to 5 with 0.08mol / L glacial acetic acid, and then place it at room temperature for 5 days of hydrolysis to obtain the vinyltriethoxysilane treatment solution;

[0043] Preparation of corrosion inhibitor-loaded multi-walled carbon nanotubes (MWCNTs): Add 0.2 g of carboxylated multi-walled carbon nanotubes into 0.001 M cerium nitrate solution, ultrasonically disperse for 2 h, then filter and dry in an oven at 80 °C , to obtain multi-walled carbon nanotubes (MWCNTs) loaded with corrosion inhibitors;

[00...

Embodiment 2

[0049] Prepared as described above,

[0050] To prepare γ-aminopropyltriethoxysilane treatment solution, add 5% (v / v) of γ-aminopropyltriethoxysilane coupling agent to deionized water (DI) / absolute ethanol drop by drop (AE) In the mixed solution (DI:AE(v / v)=5:90), the volume ratio of the γ-aminopropyltriethoxysilane coupling agent: the mixed solution of deionized water and absolute ethanol is 5%; the mixed solution was placed on a magnetic stirrer and stirred at a rate of 800rpm for 50min, and the pH value was adjusted to 5 by using 0.08mol / L glacial acetic acid, and then it was placed at room temperature and hydrolyzed for 5 days to obtain γ-aminopropanol Base triethoxysilane treatment fluid;

[0051] Take 100ml of γ-aminopropyltriethoxysilane silane treatment solution, add 0.5g of carboxylated multi-walled carbon nanotubes into 0.003M cerium nitrate solution, ultrasonically disperse for 2 hours, then filter and dry in an oven at 60°C , to obtain multi-walled carbon nanotub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Contact angle | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com