Method for discriminating nonlinearity of pressure sensors under influence of internal stress

A technology of pressure sensor and discrimination method, applied in the direction of measuring fluid pressure, instrument, force/torque/work measuring instrument calibration/test, etc., can solve the problems of film structure damage, film peeling, cracking, etc., and achieve high accuracy , The method is simple, the effect of optimizing the design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

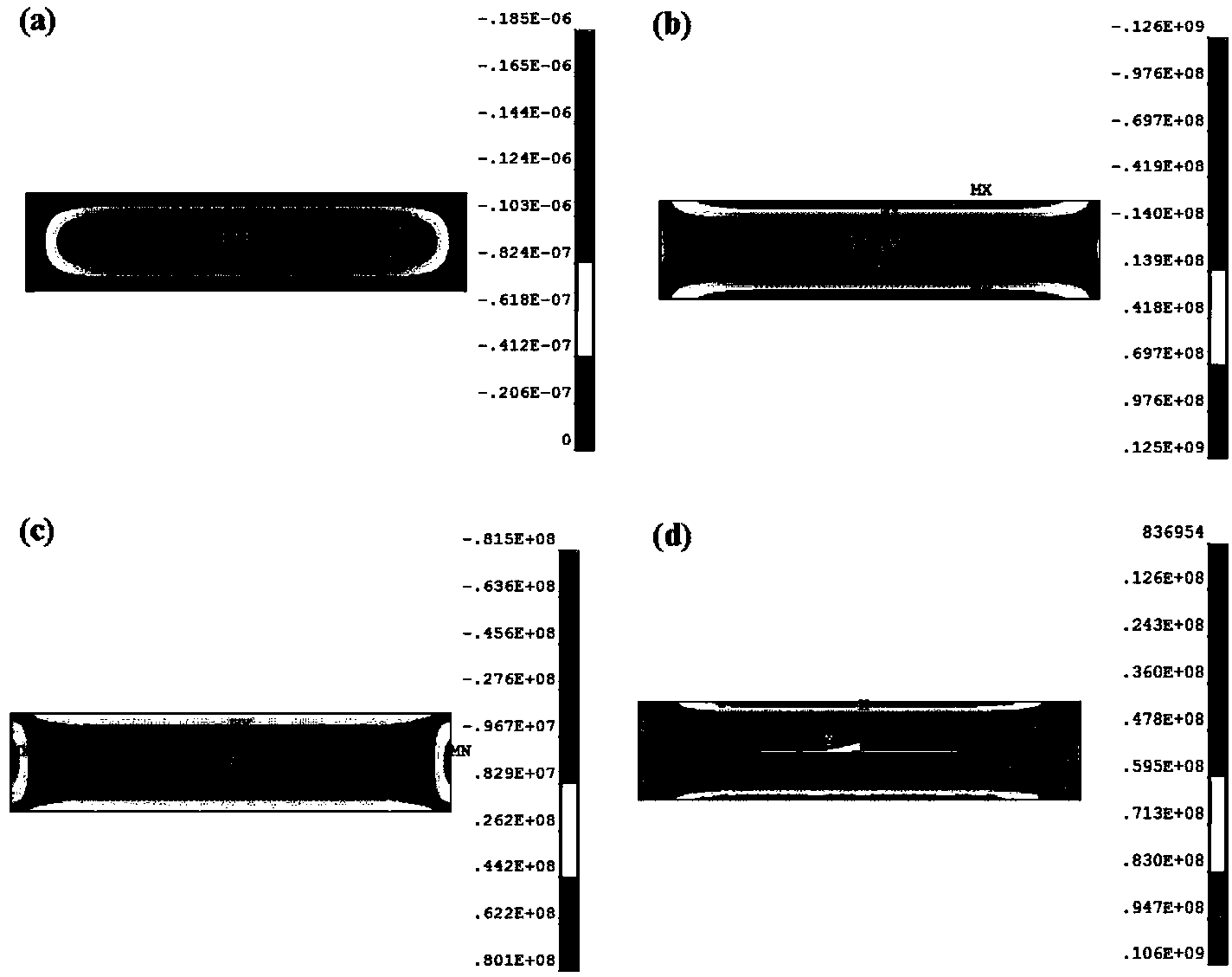

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

[0028] Taking a low-stress silicon nitride film as an example of a pressure sensor structural layer film, the non-linear discrimination method of an absolute pressure sensor under the influence of internal stress according to the present invention is described in detail.

[0029] First, the low-pressure chemical vapor deposition (LPCVD) method is used to adjust the flow ratio of dichlorodihydrogen silicon and ammonia, and at a growth temperature of 850 ° C, a low-stress silicon nitride film (LS SiN for short) is deposited, and this low The stressed silicon nitride film is used as the structural layer film of the pressure sensor chip.

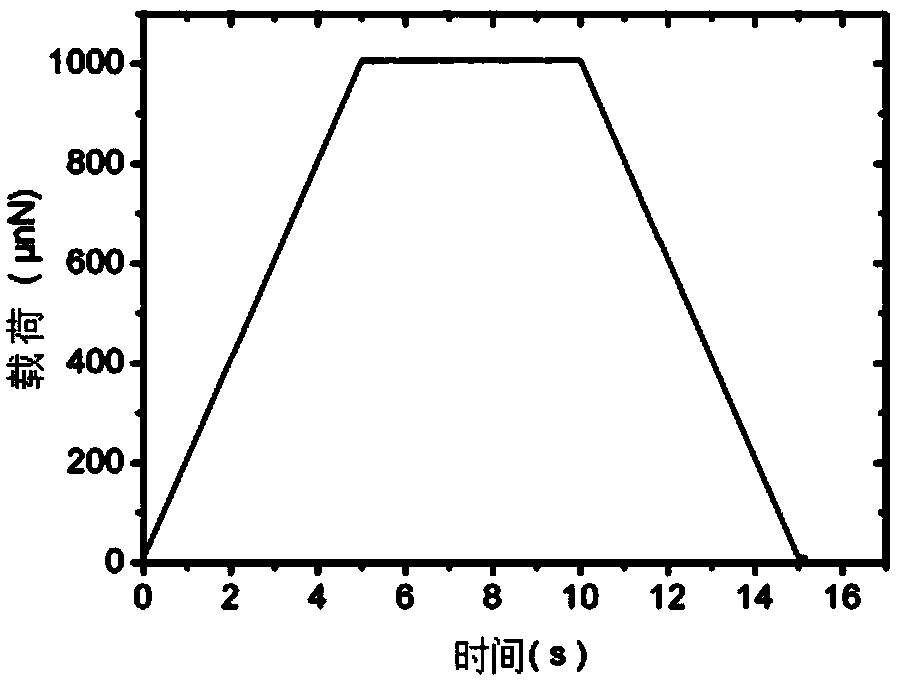

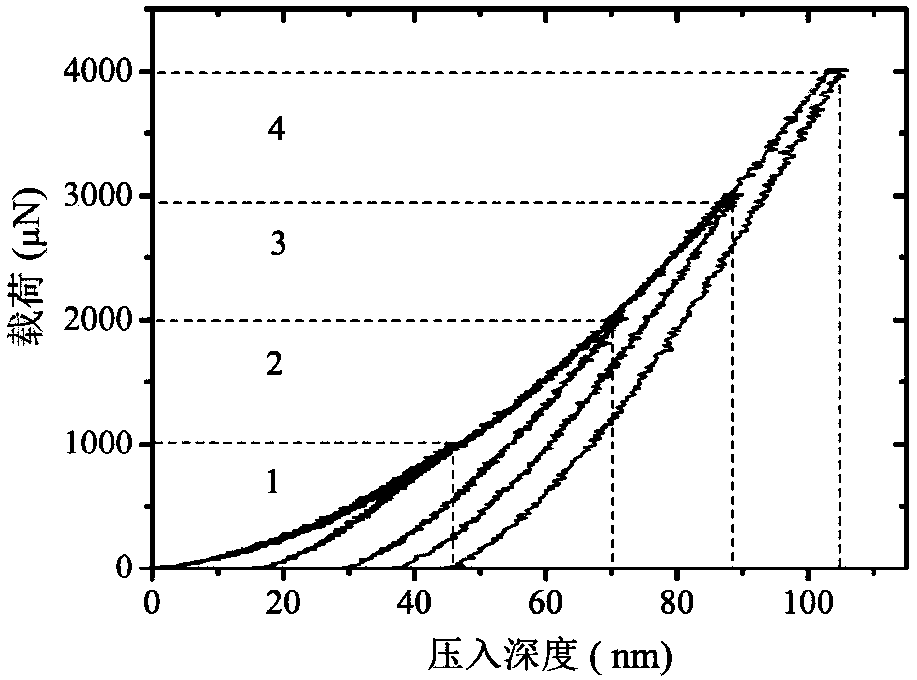

[0030] Using Hysitron's TriboIndenter nano-indentation system, the Young's modulus of LS SiN is obtained through continuous control and re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com