Light steel side frame and main rib type single-row reinforcement recycled-concrete shear wall and construction method

A technology of recycled concrete and shear walls, applied to walls, building components, buildings, etc., can solve the problems of insufficient seismic research of multi-storey buildings, and achieve the effects of sustainable development, small seismic force and obvious seismic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific embodiments.

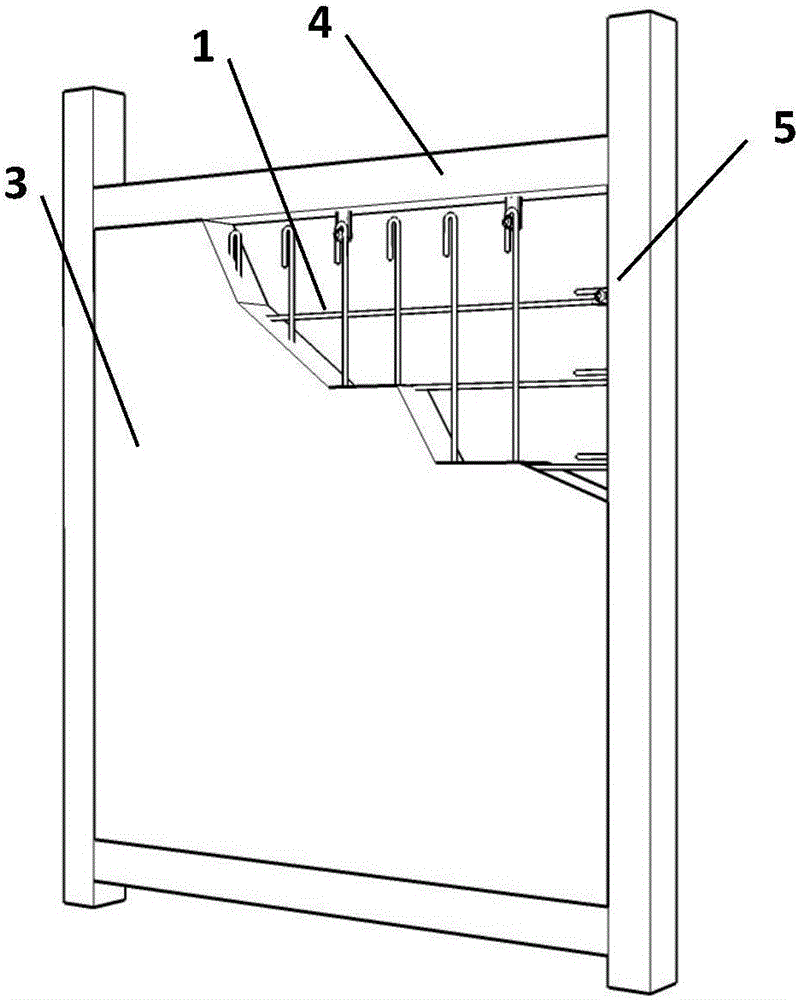

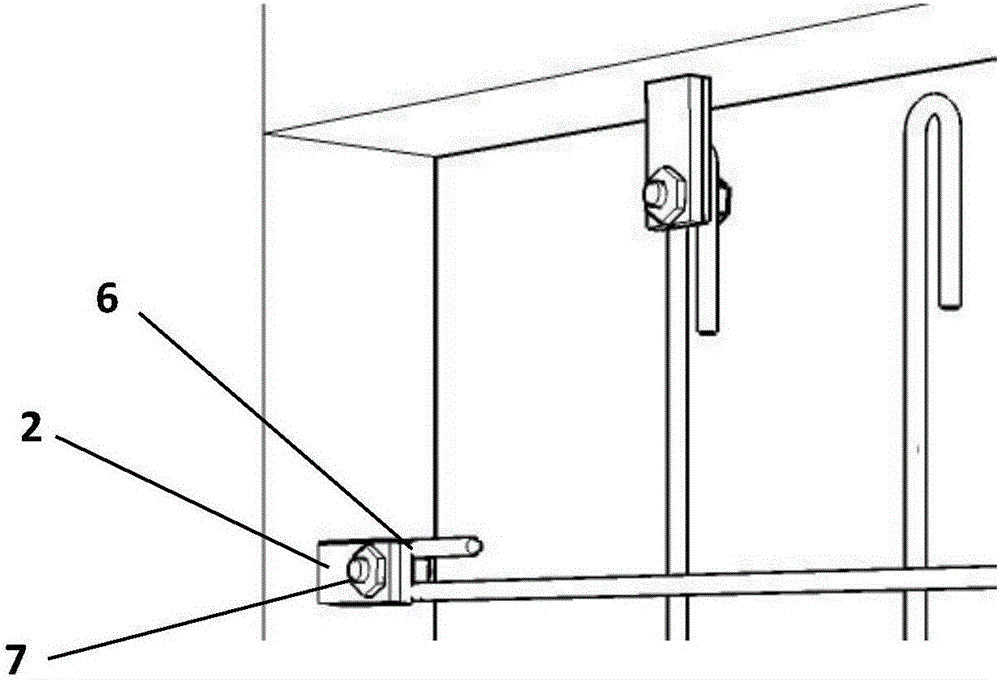

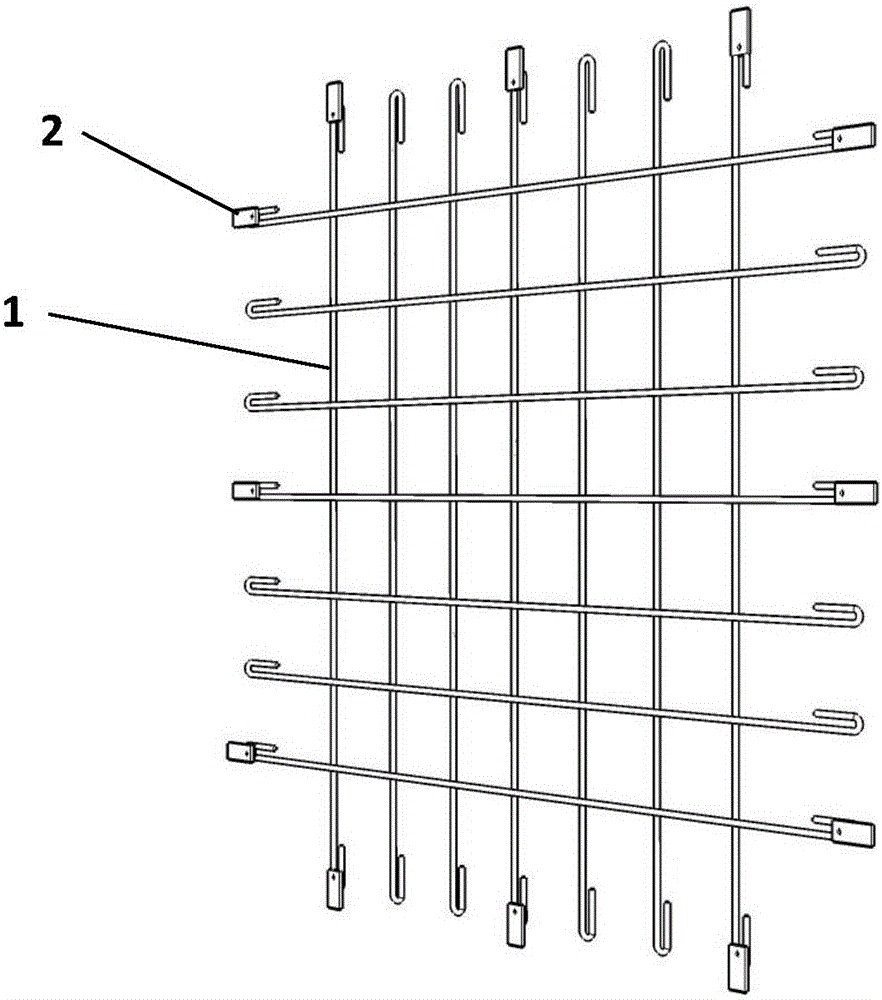

[0032] Such as figure 1 As shown, a light steel frame-main reinforcement type single-row reinforcement recycled concrete shear wall structure, the combined structure is composed of end curved main reinforcement type single row steel mesh (1), thin steel sheet (2), main reinforcement type single row It consists of a recycled concrete shear wall (3), light steel beams (4), light steel columns (5), lug plates (6), and bolts (7) with row reinforcement.

[0033] The single-row reinforcement mesh sheet (1) with curved main reinforcement at the end, and the distribution distance of the single-row reinforcement with the main reinforcement type is 200mm-300mm; the single-row reinforcement mesh with curved main reinforcement at the end (1) is located in the middle of the wallboard thickness to prevent Eccentric force.

[0034] The thin steel sheet (2) is welded around the bent main...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com