Chain armor type flap valve

A flap valve and lock technology, which is used in lift valve, valve device, earthwork drilling, etc., can solve the problems of inability to maintain pressure, occupy large space, and low matching success rate, and achieve strong valve disc deformation ability and sealing. Reliable performance and high matching success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

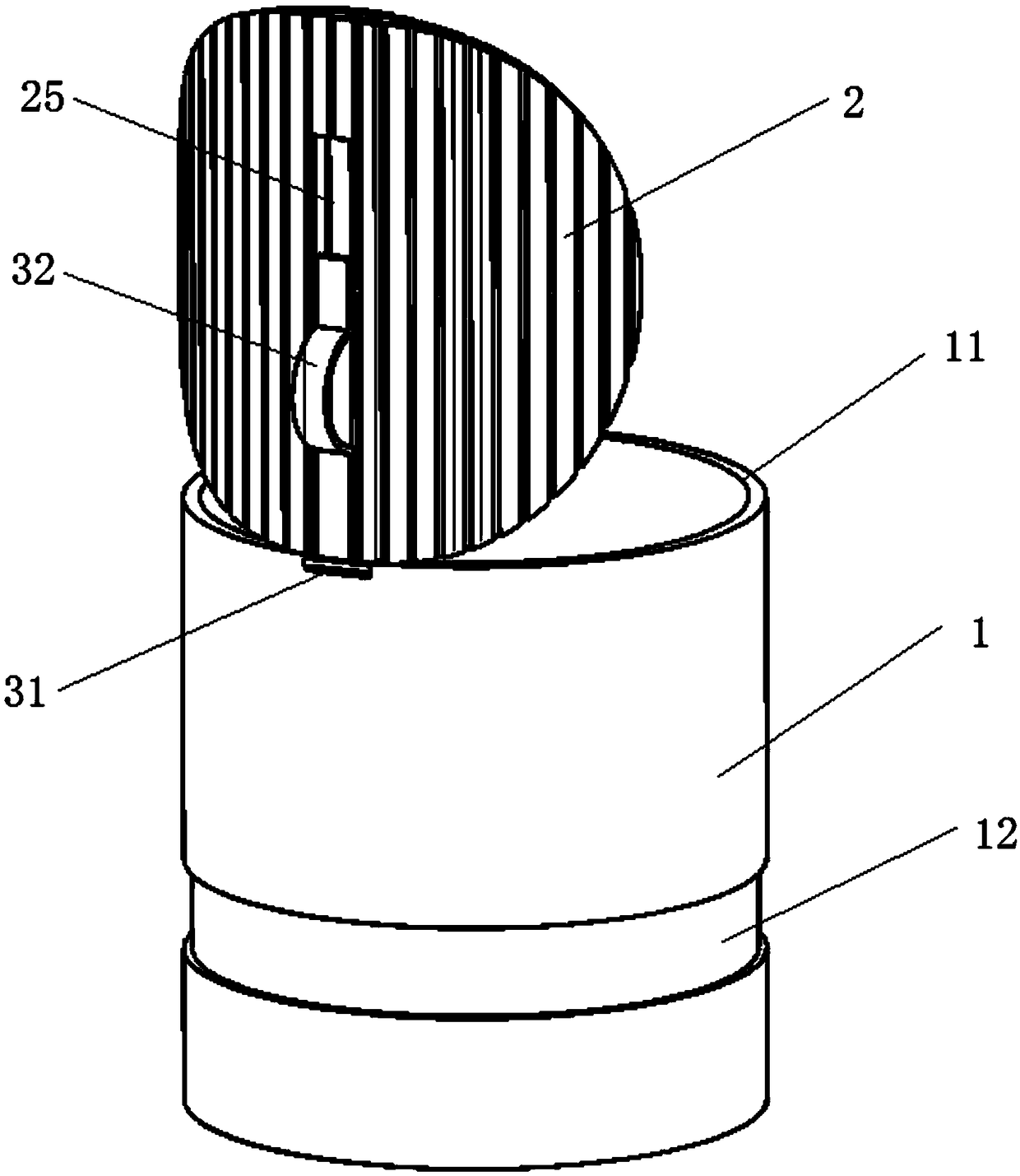

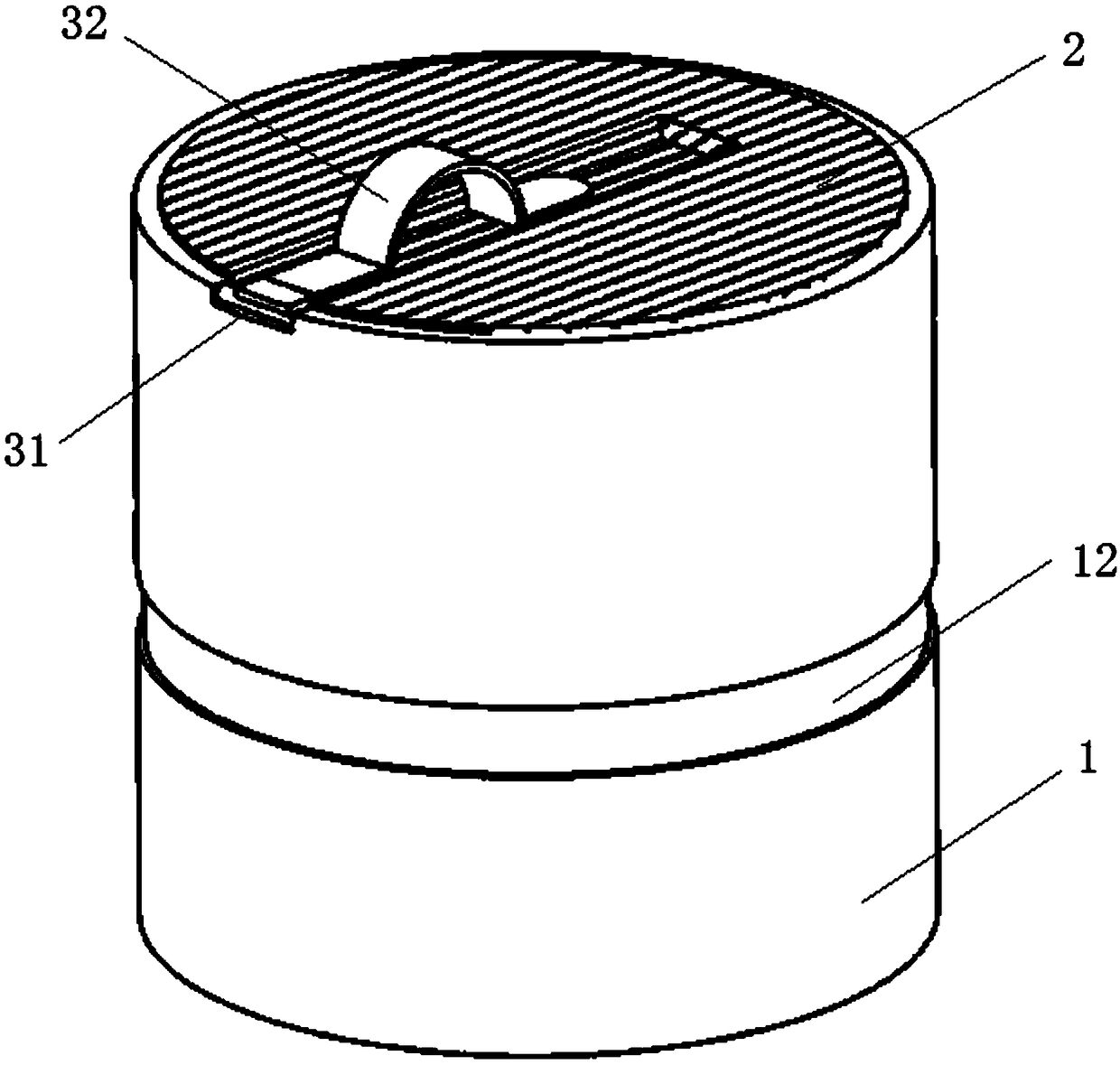

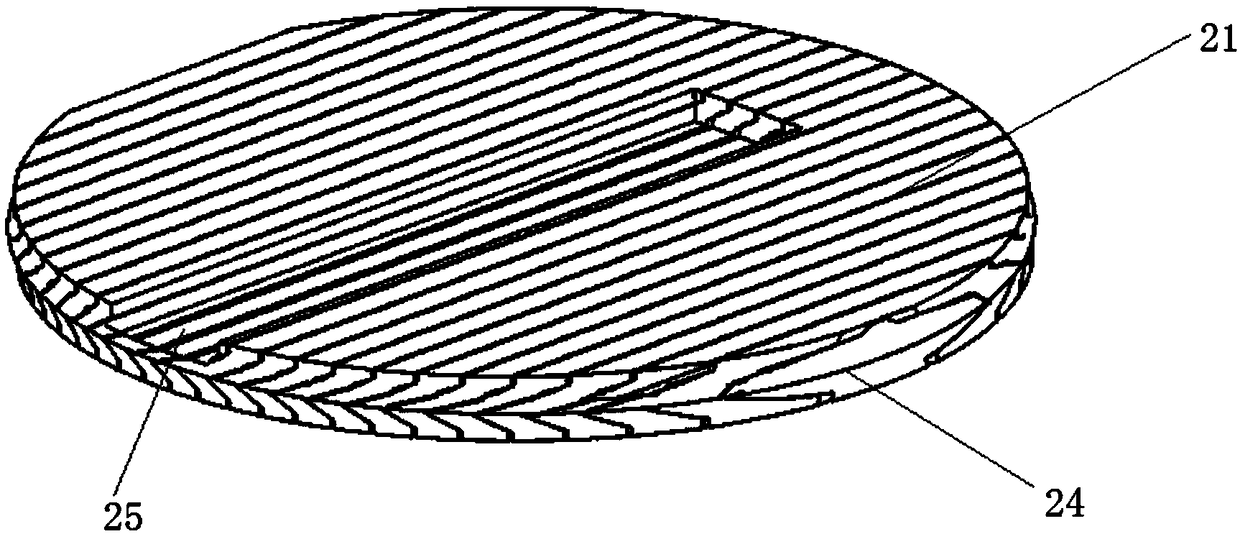

[0036] Such as Figure 1-10 As shown, the chainmail type flap valve disclosed by the present invention comprises a valve seat 1 and a chainmail type valve flap 2, and the valve flap 2 includes an elastic sealing ring 24, an elastic connecting strip 22, a sealing member 23 and a plurality of Locking bars 21 arranged in parallel. There are at least three locking bars 21, and the number of locking bars 21 is determined according to the size of the sealing surface of the valve port. The elastic connecting strip 22 connects all the locking strips 21 in series and the elastic sealing ring 24 hoops all the locking strips 21 together to form an integral structure. Tighten the hoop, when the valve flap 2 or the locking strip 21 is subjected to external force, the locking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com