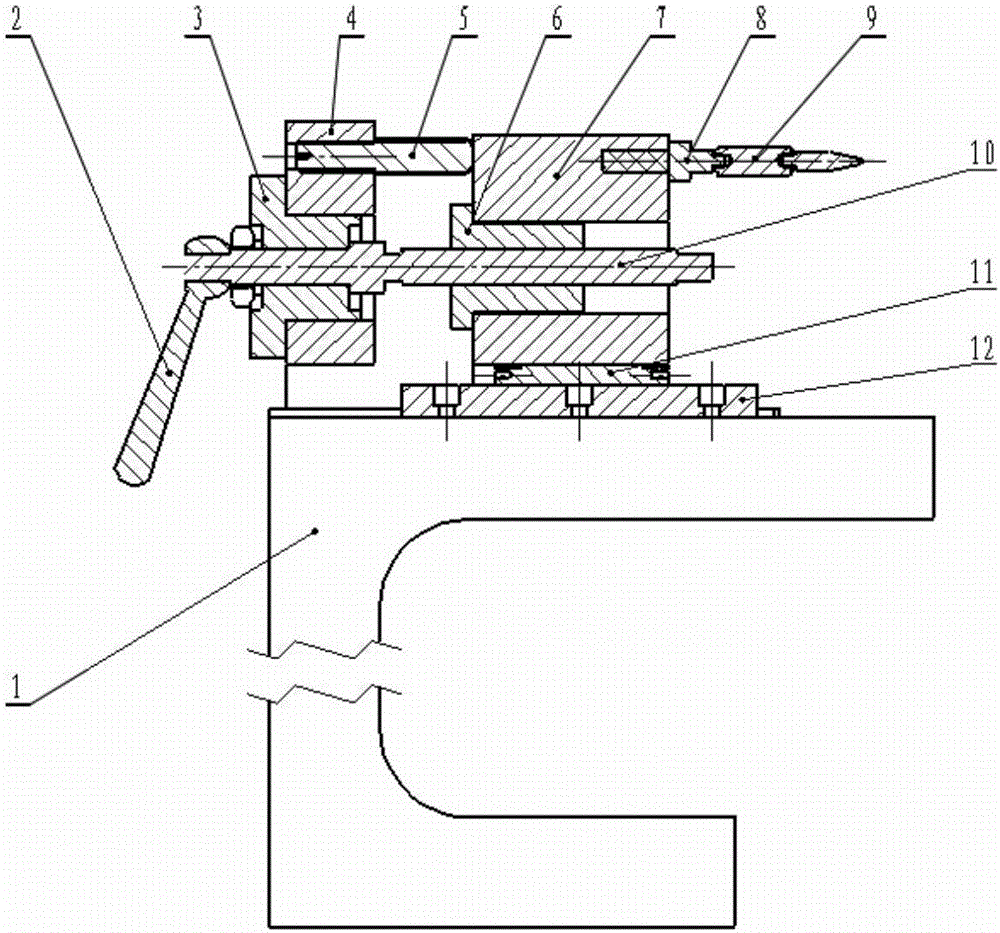

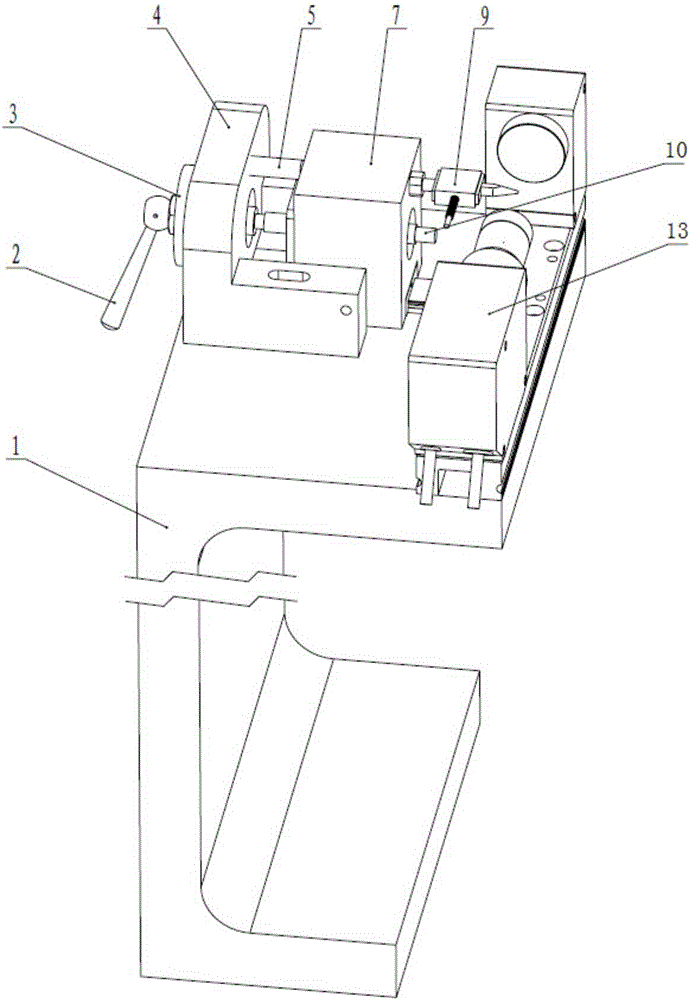

Online measurement system for measuring part deflection

A detection system and component technology, applied in the field of deflection measurement, can solve problems such as low reliability, large detection error, and inability to obtain measurement curves, and achieve the effect of overcoming the influence of human factors and improving efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Install the base frame 1 on the EDM machine table, and install a fixture on the Z-direction spindle of the EDM machine to clamp the component under test. The component under test and the displacement sensor 13 are aligned, and the top of the pressure sensor 9 is positive. Facing the lower end of the component under test; the pressure sensor 9 is the FUTEK load cell LSB200-100G, its sensitivity is 22.482mV / N, and the maximum range is 445N. The displacement sensor 13 is the Keyence TM-006 laser displacement sensor 13, the sensitivity is 0.04mm, and the measurement range is The specific operation is as follows: slowly twist the adjustment handle 2 to make the top of the pressure sensor 9 slowly approach the lower end of the measured part, and continuously adjust until the pressure sensor 9 just touches the measured part. At this time, set the output value of the pressure sensor 9 and the displacement sensor 13 to 0; then slowly twist the adjustment handle 2 to continuousl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com