Soil pressure sensor mounting, loading and testing device, and operating method thereof

An earth pressure sensor and testing device technology, applied in the field of farmland soil monitoring, can solve the problems of lack of suitable equipment, time-consuming and laborious testing process, lack of standardized operation methods, etc., and achieve the effects of suitable promotion and use, simple structure and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

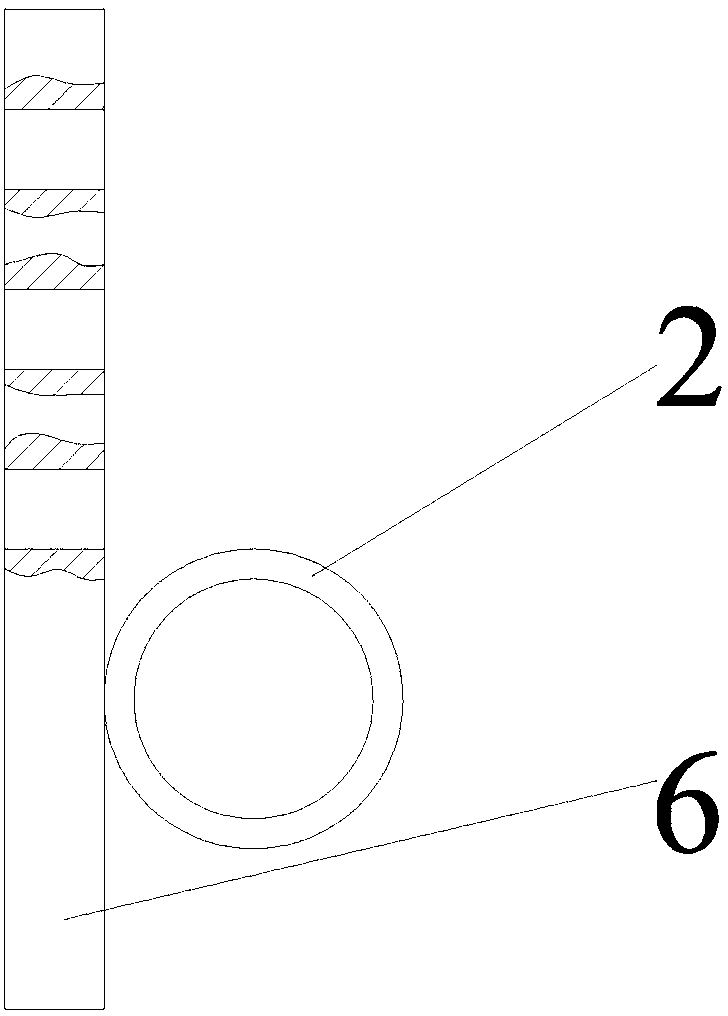

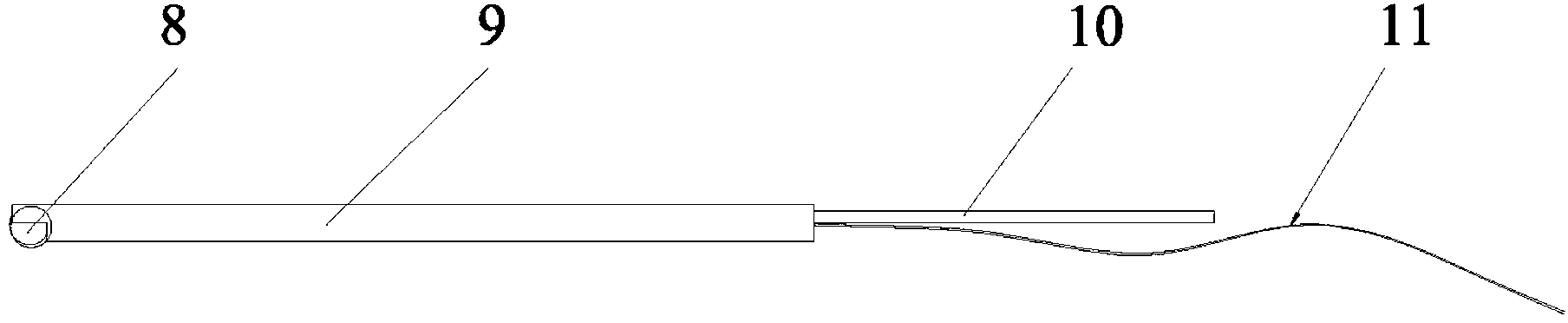

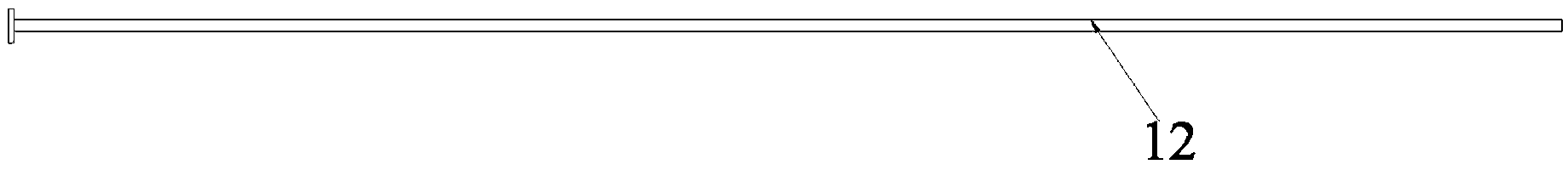

[0031] Such as Figure 1-5 Shown: a loading test device for installing an earth pressure sensor, including a punching mechanism, an embedding mechanism and a loading testing mechanism, wherein the punching mechanism includes a bracket 3 that can move on a rail 5 fixed by anchors 18, and the bracket 3 is mounted There is a guide sleeve 2 with an adjustable angle, and the guide sleeve 2 is welded on the angle plate 6; the angle plate 6 rotates to change the angle between the guide sleeve 2 and the ground; the rotatable angle plate 6 is arranged on the bracket 3 On the fixed plate 7; the guide sleeve 2 is equipped with a soil fetcher 1 that can slide up and down inside it and has a scale. The soil fetcher 1 includes a circular soil fetcher and a square soil fetcher. Retrieve soil with square earth taker after, to guarantee that the hole wall of earth pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com