Damping rubber with low cost and high damping performance and manufacturing method thereof

The technology of damping rubber and damping agent is applied in the field of damping rubber with low cost and high damping and its preparation, which can solve the problems of high cost and high cost of small organic molecules, and achieve the effects of improving stability and wide effective damping temperature range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4 and

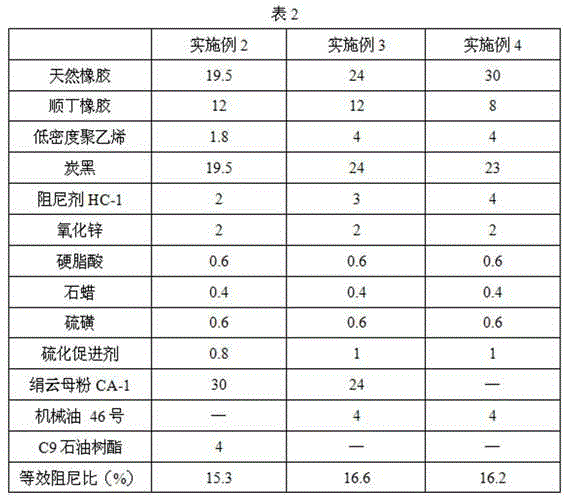

[0055] Embodiment 1-4 and reference example 1-4

[0056] The damping rubbers in the following embodiments and reference examples of the present invention are all prepared by the following methods, and the difference between each embodiment and reference examples is only that the content of each component raw material is different:

[0057] 1) Add the natural rubber, butadiene rubber and low-density polyethylene in the parts by weight shown in Table 1 (or Table 2) to an internal mixer and mix at a temperature not exceeding 150°C, and cool down after mixing spare;

[0058] 2) Add the damping agent HC-1 (or organic small molecule NT636), carbon black, zinc oxide, stearic acid in parts by weight shown in Table 1 (or Table 2) to the product after the mixing in step 1) , paraffin, sulfur, vulcanization accelerator, sericite powder CA-1, machine oil No. 46 (or C9 petroleum resin), mixed at a temperature not exceeding 120°C for 5-7 minutes, unloaded, and cooled for later use;

[005...

Embodiment 1

[0063] Embodiment 1 is compared with reference example 1-2, and reference example 1 is the damping rubber that adopts traditional formula to make, and reference example 2 is the damping rubber that adopts organic small molecule to make, and it can be seen that the damping rubber of formula shown in the present invention Compared with the equivalent damping ratio of rubber, the equivalent damping ratio of the damping rubber of the formula shown in reference example 1 is 5 percentage points higher, which has a significant difference, and p is less than 0.05, while the equivalent damping ratio of the damping rubber of the formula shown in reference example 2 Roughly equal.

[0064] Compare in terms of cost: the small organic molecule NT636 used in reference example 2 is expensive, and the current market price is about 300 yuan / kg, resulting in the cost of the damping rubber prepared in reference example 2 being about 50-60 yuan / kilogram; The cost of the damping rubber that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com