Dual-edge eccentric copper-foil punching tool with improved structure

A hole cutter and double-edged technology, applied in drilling accessories, manufacturing tools, drilling/drilling equipment, etc., can solve problems such as unfavorable quality, hidden dangers, copper foil tearing, etc., and achieve convenient processing and no tearing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

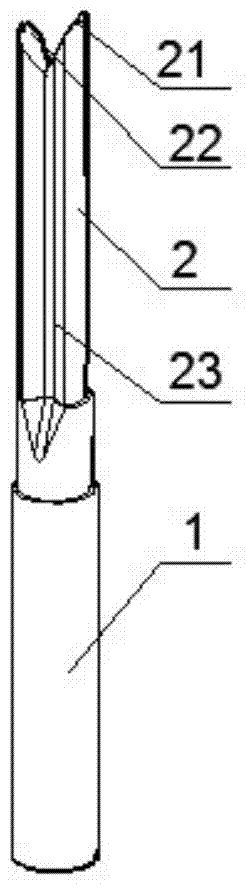

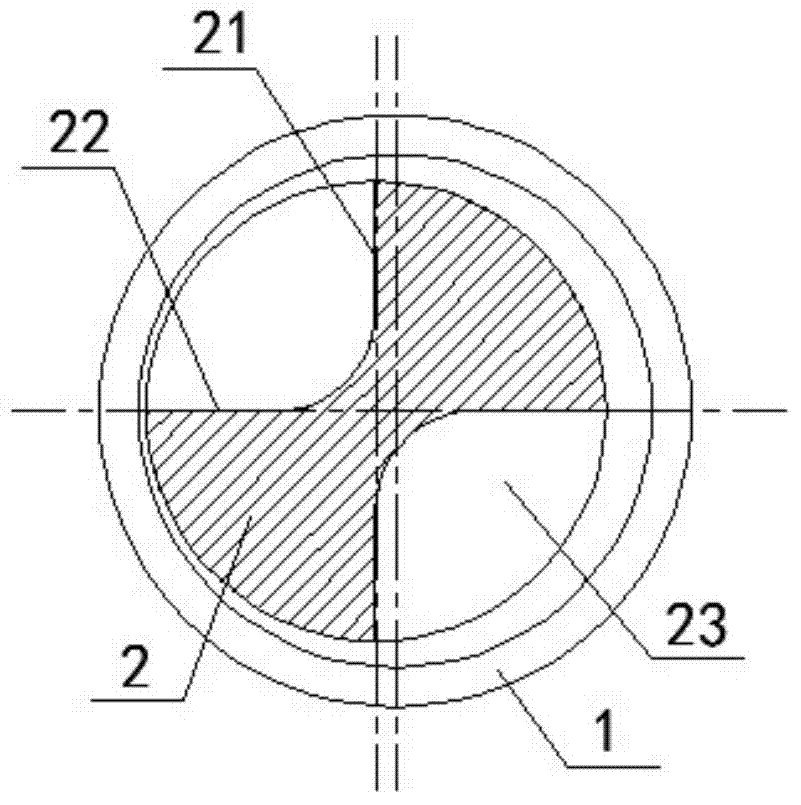

[0018] Such as figure 2 As shown, a double-edged eccentric copper foil punching tool with an improved structure includes a handle 1 and a blade 2, and the blade 2 is a double-edged body structure including a main cutting edge 21 and a minor cutting edge 22. A chip removal groove 23 is provided between the cutting edge 21 and the blade body of the minor cutting edge 22, and the chip removal groove 23 is used to discharge copper slag waste generated during drilling in time. 0.5-2.0 mm longer than the tip of the minor cutting edge 22 . The blade 2 and the handle 1 are eccentric structures (such as image 3 As shown), the axis of the cutting edge 2 deviates 0.2-0.3 mm toward the minor cutting edge 22 compared with the axis of the handle 1 .

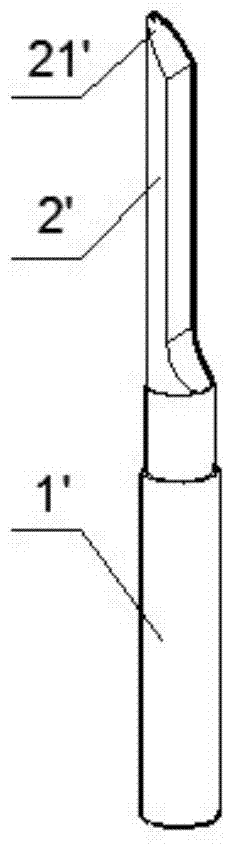

[0019] figure 1 Shown is a single-edged cutter in the prior art, comprising a single-edged cutter handle 1' and a single-edged cutter blade 2', the single-edged cutter blade 2' has a single-edged cutter cutting edge 21', and after the sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com