Supplementing method for cartons of cigarettes and vertical sorting system adopting same

A sorting system and smoke replenishment technology, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of unable to replenish smoke in time, occupy a large area, and miss fill, so as to improve the continuity of sorting and occupy an area Small, the effect of improving sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

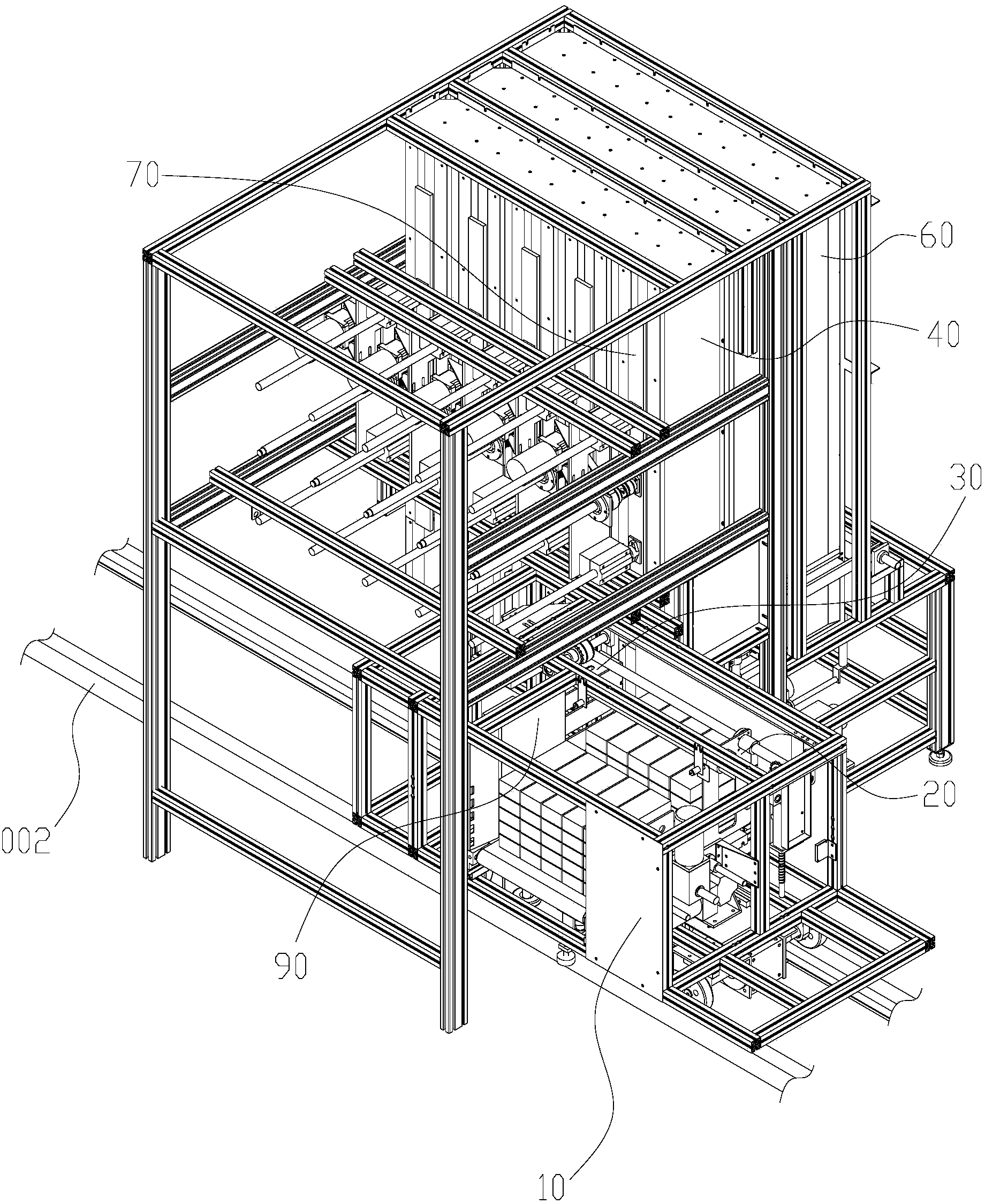

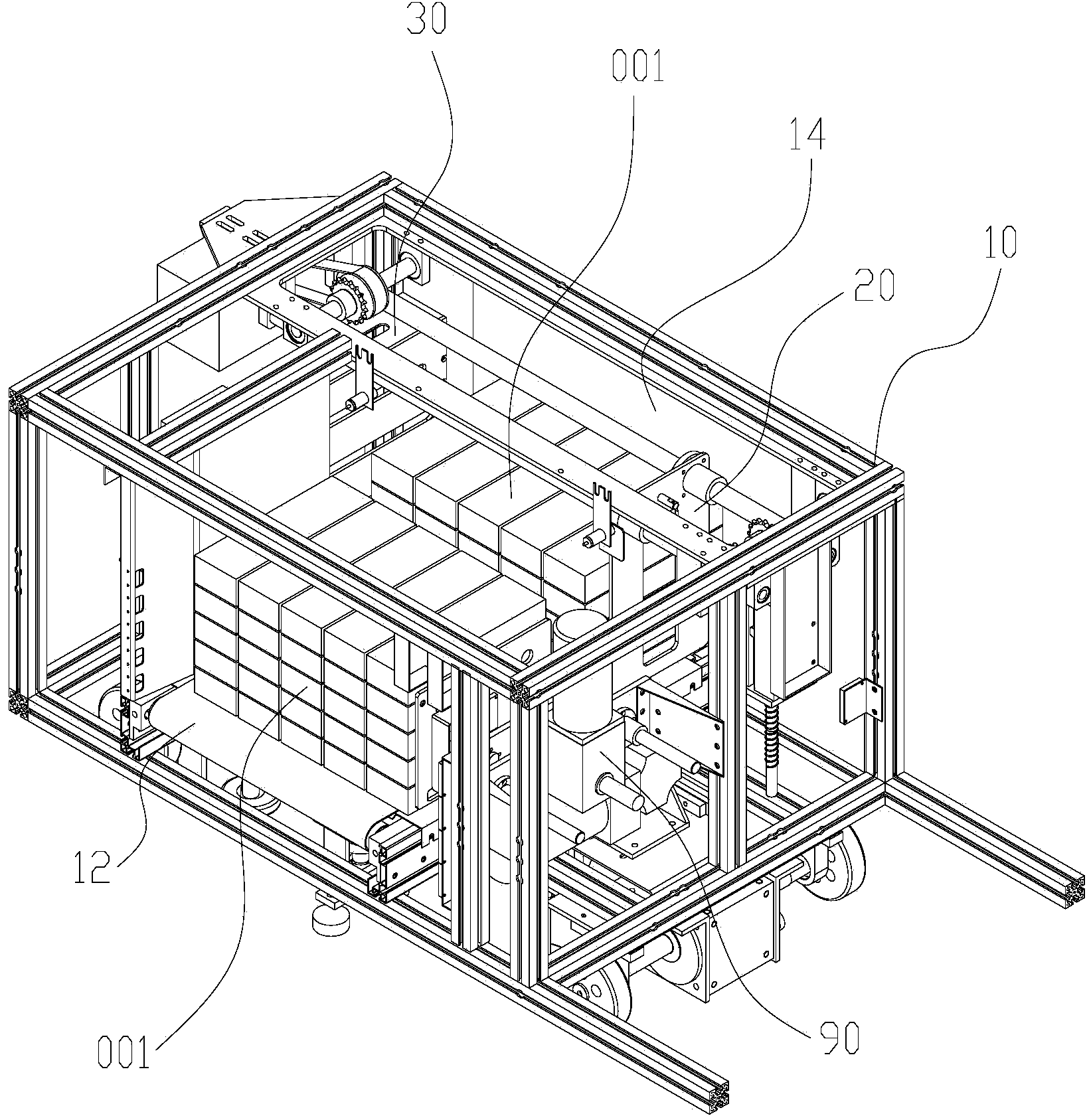

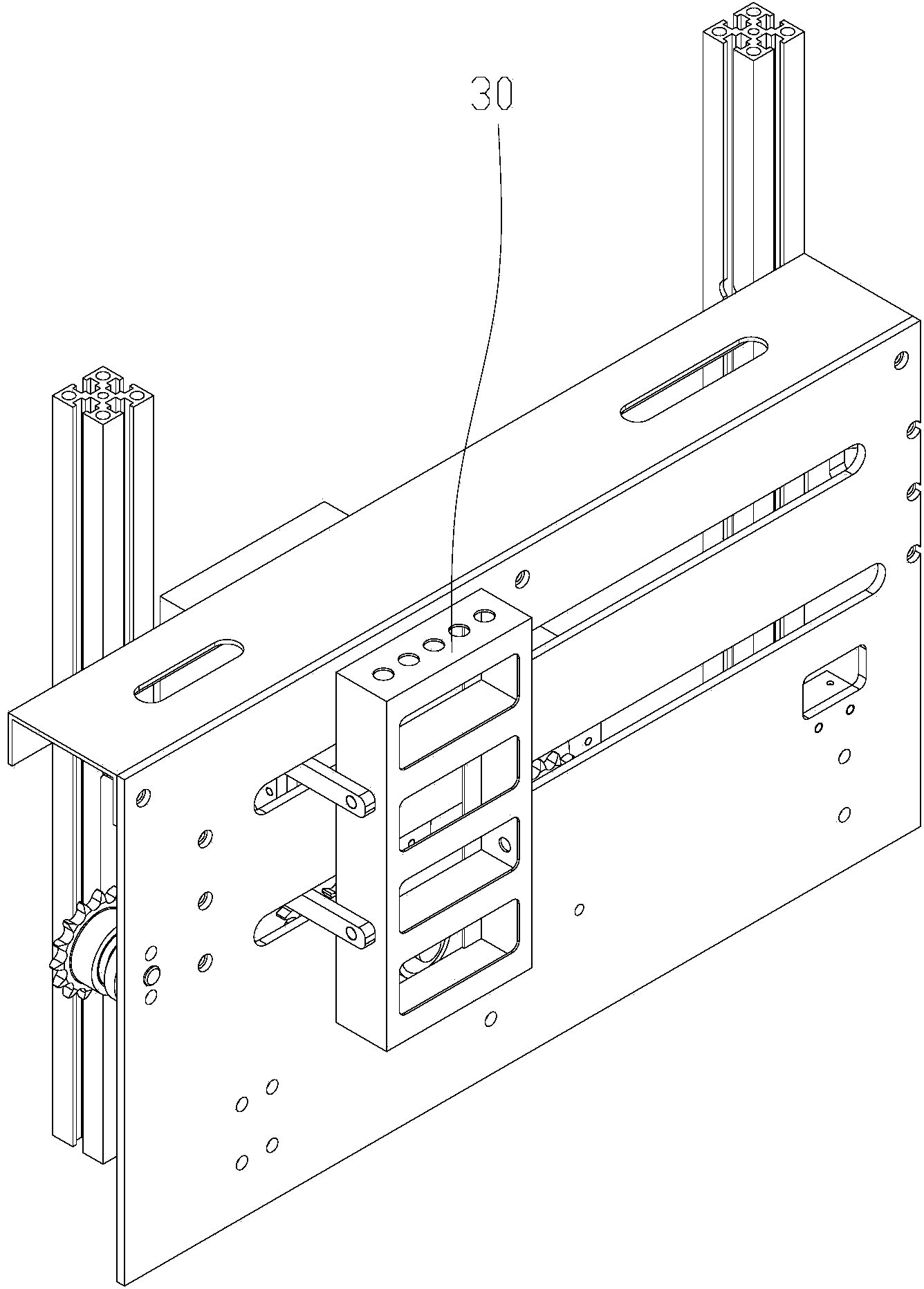

[0042] Please refer to figure 1 and figure 2 , a vertical sorting system of the present invention, comprising: a cigarette replenishing trolley 10, a horizontal tobacco pushing mechanism 20, a longitudinal tobacco pushing mechanism 30, a vertical buffering tobacco bin 40, a jacking mechanism 50, and a vertical sorting tobacco bin 60 , push the smoke plate 70 vertically, press the smoke shrapnel 80 (such as Figure 6 Shown), cigarette clamping mechanism 90. The invented vertical sorting system is used to realize stacks 001 of cigarettes discharged in 5 layers and 5 rows, stacked up to form a vertical column of cigarettes, and placed in the vertical buffer storage bin 40 or vertical sorting cigarette Among the warehouses 60.

[0043] The cigarette filling trolley 10 can move laterally and reciprocatingly on the track 002 . The smoke filling trolley 10 is provided with a longitudinal conveying roller table 12 and a smoke baffle 14 . There are 50 cigarettes in a box, which c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com