Wide width lock and fold laminate

a wide width and lock technology, applied in the field of flooring, can solve problems such as loss of desired friction, and achieve the effect of increasing the force for disengagement of panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

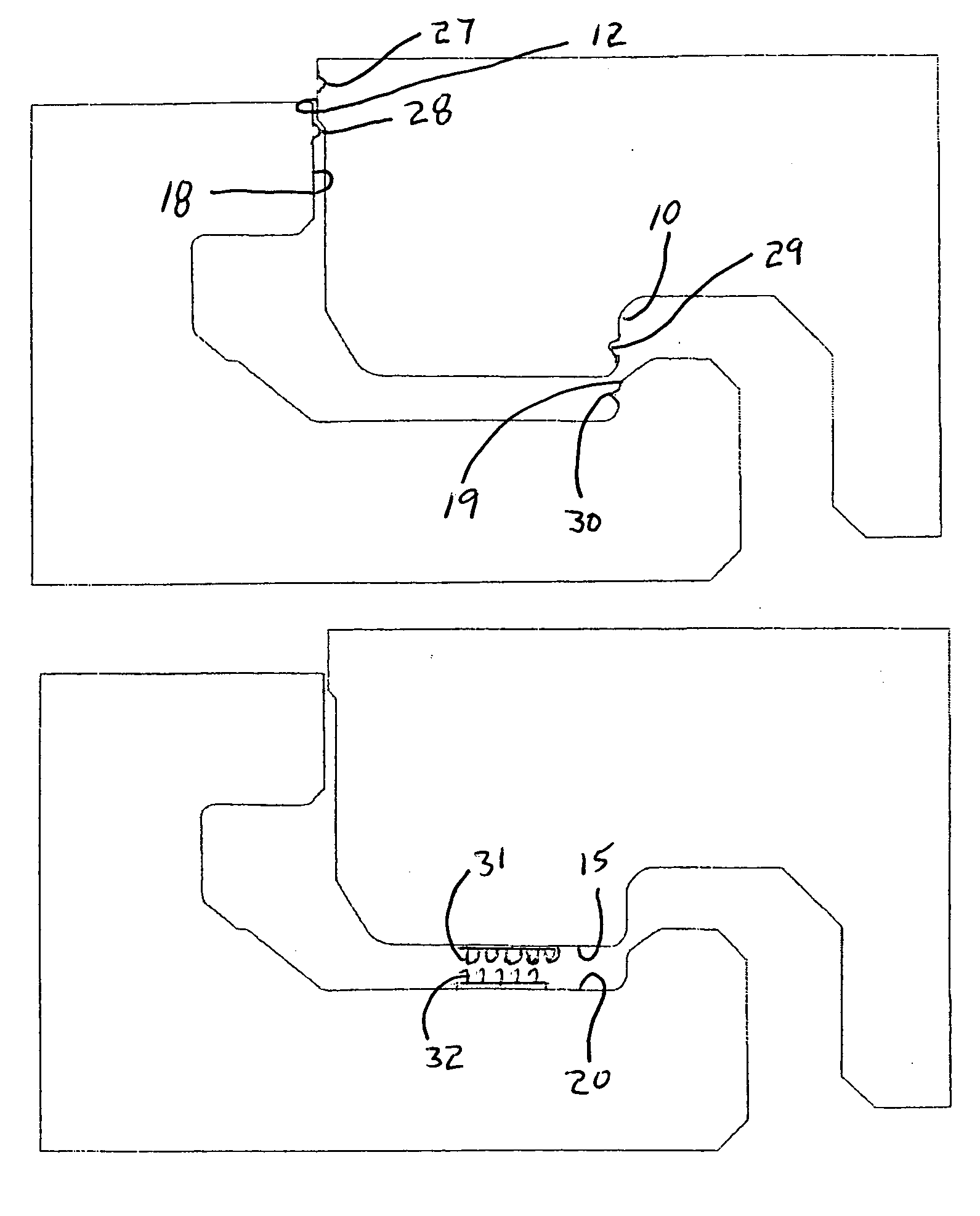

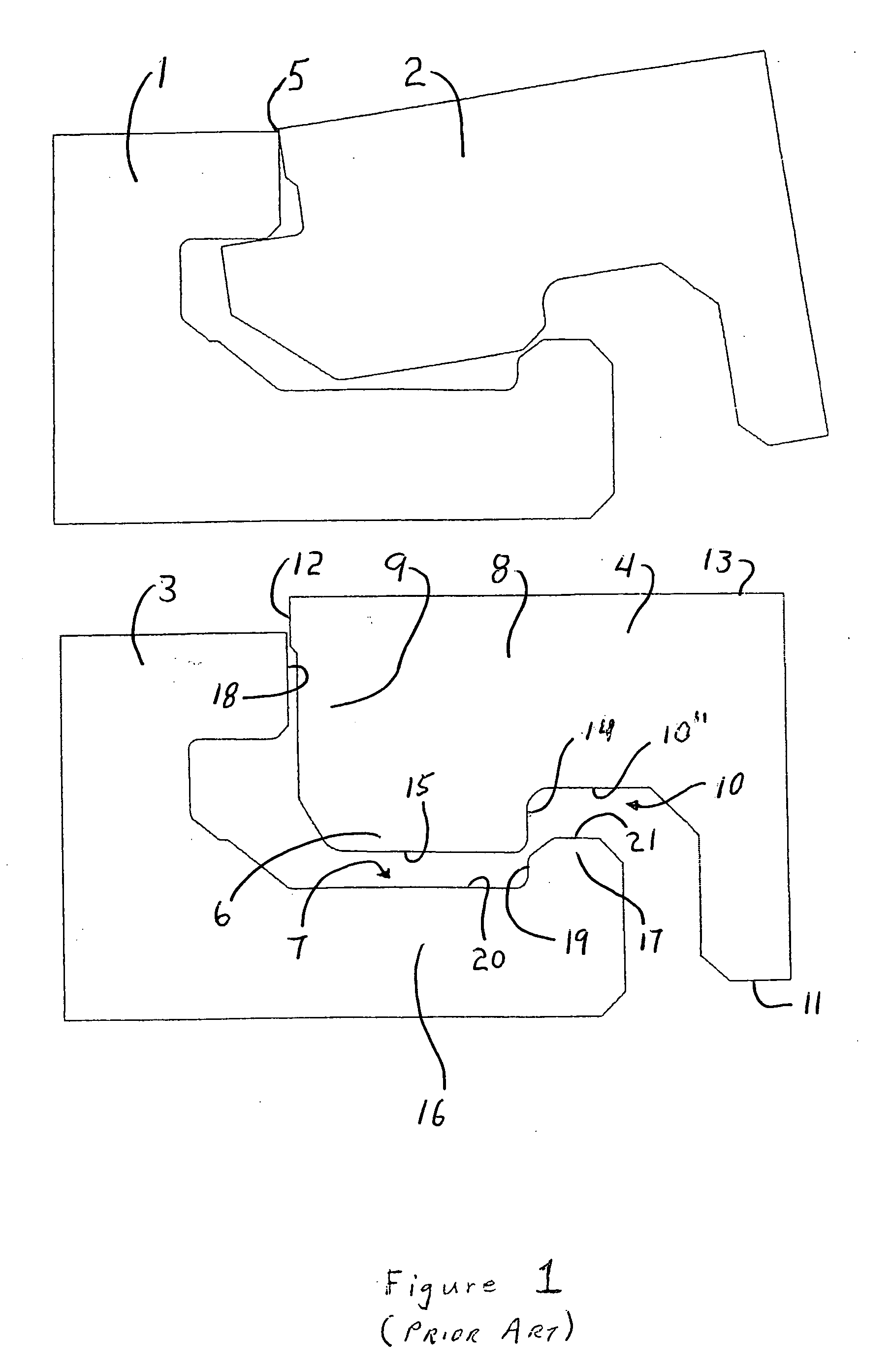

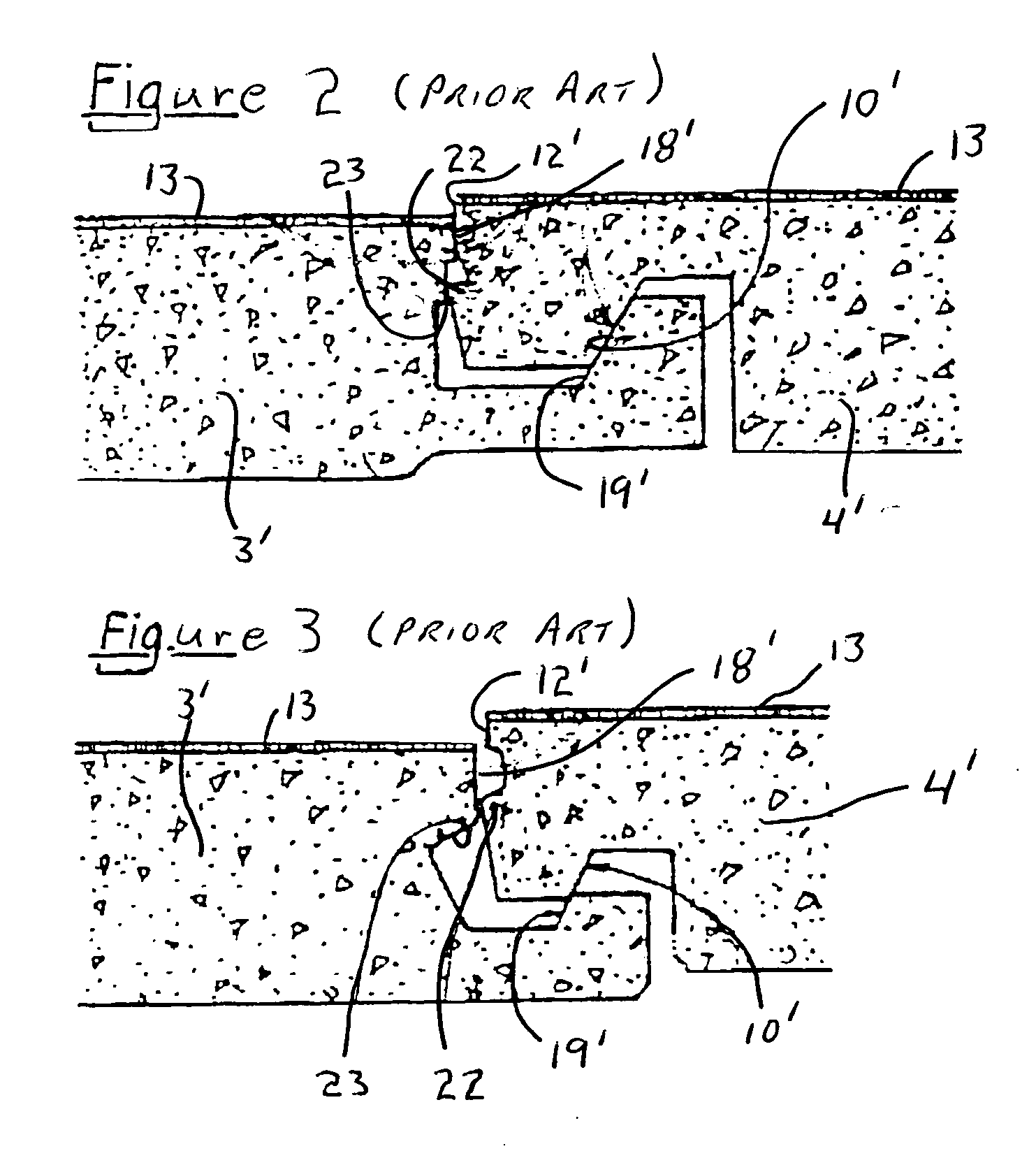

[0037]FIG. 1 shows the lock and fold profile of the prior art. The opposite long edges had the standard locking profile as shown on panels 1 and 2 in FIG. 1. The other two short opposite edges are shown on panels 3 and 4 in FIG. 1. These lock and fold panels were installed by angling a long locking edge of panel 2 into a previously installed row of panels such as panel 1. Panel 2 is then rotated about the contact point 5 between panels 1 and 2, thereby dropping or locking the locking projection 6 of short side into the locking groove 7 in the other short side.

[0038] The upper lip locking projection 6 is formed on the upper lip 8 of the short side of panel 4 between the distal end 9 and the upper lip proximal groove 10. The upper lip proximal groove 10 is formed between the upper lip locking projection 6 and the body of the panel 4 adjacent the lower surface 11. The upper lip 8 includes an upper lip distal contact surface 12 and an upper lip proximal contact surface 14. The upper li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com