Methods for preparing graphene or graphene oxide

A technology of graphene and graphite, which is applied in the field of preparation of graphene or graphene oxide, can solve problems such as difficulties, and achieve the effects of weakening damage, high collision frequency, and high grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Use 100g of a 0.3×5mm magnetic stainless steel needle and 10g of 300-mesh graphite powder into a 300ml plastic grinding container, turn on the rotating magnetic field, the magnetic field switching frequency is 1800r / min, the magnetic induction at the bottom of the grinding container is 0.2T, and stop after 12h. The graphite and the steel needle are taken out from the plastic container, and subjected to magnetic separation to obtain the graphite nano-microflake-graphene dry powder mixture.

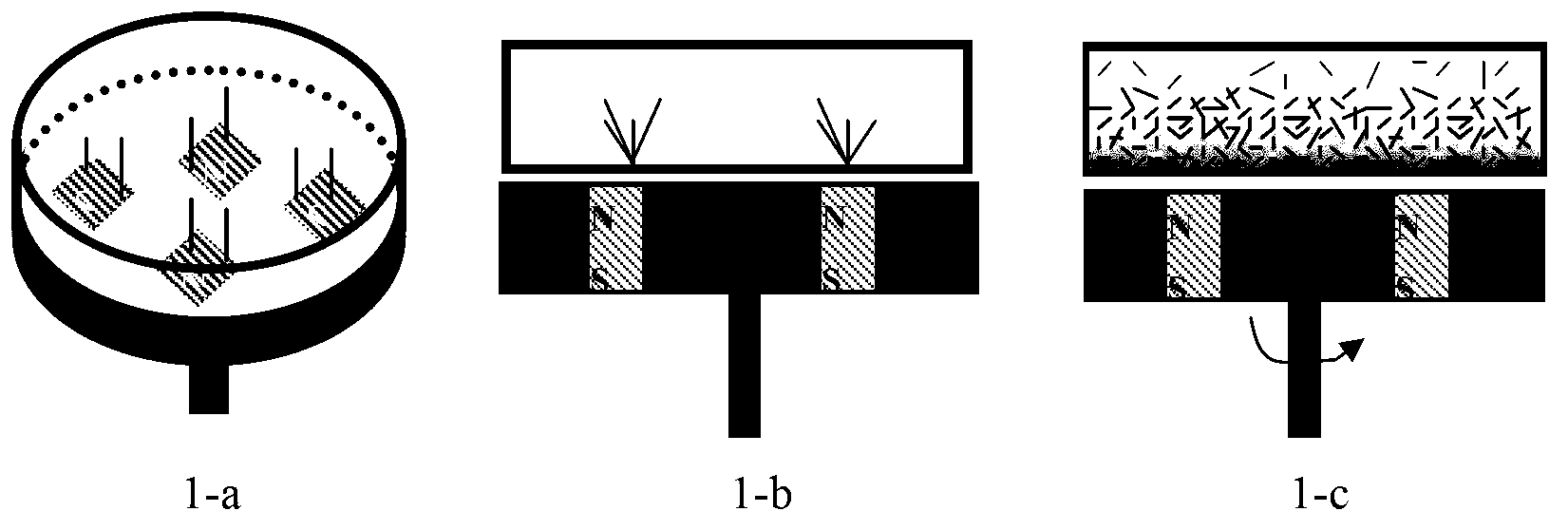

[0064] The schematic diagram of the device is as figure 1 As shown, the present embodiment adopts 4 permanent magnets to form the magnetic field transformation space above the plane, figure 1 -a is a schematic diagram of the three-dimensional state of the magnetic stainless steel needle being attracted by the magnet when it is at rest, figure 1 -b is a schematic diagram of a magnetic stainless steel needle being attracted by a magnet at rest, figure 1 -c is a schematic diagram of t...

Embodiment 2

[0066] Use 200g of 0.5×5mm magnetic stainless steel needle, 10g of 300 mesh graphite powder, 0.5g of aluminate coupling agent, put them into a 500ml ceramic grinding container, turn on the rotating magnetic field, the magnetic field switching frequency is 1500r / min, and the magnetic induction at the bottom of the grinding container The strength is 0.1T, stop after 8h, take out the graphite and steel needle from the container, and obtain the graphite nano-flake-graphene mixture through magnetic separation, mix it with graphite nano-flake-graphene with 2000ml ethanol, and after ultrasonication for 4h, After settling for 24 hours, take the upper layer suspension and centrifuge at 3000r / min for 1 hour. What settles is the nanographite microflakes, and the upper layer is the suspension of graphene.

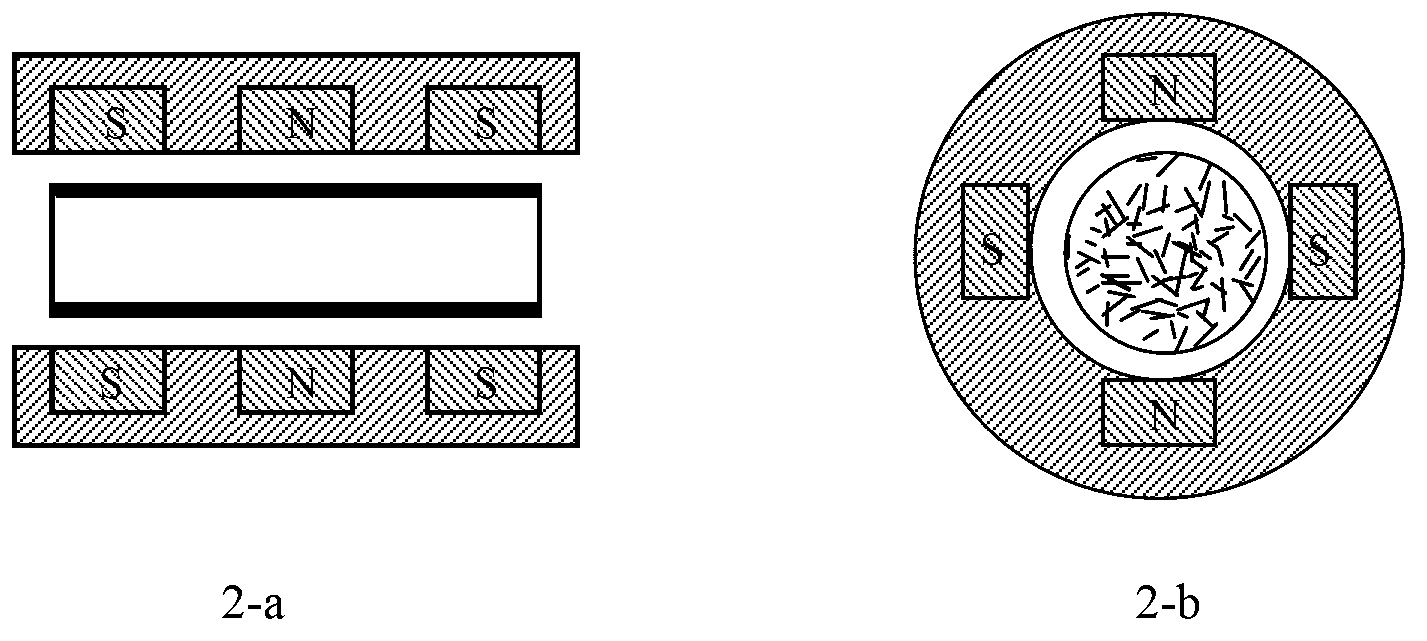

[0067] The schematic diagram of the device is as figure 2 As shown, the present embodiment adopts four permanent magnets to form a cylindrical transformed magnetic field space, figu...

Embodiment 3

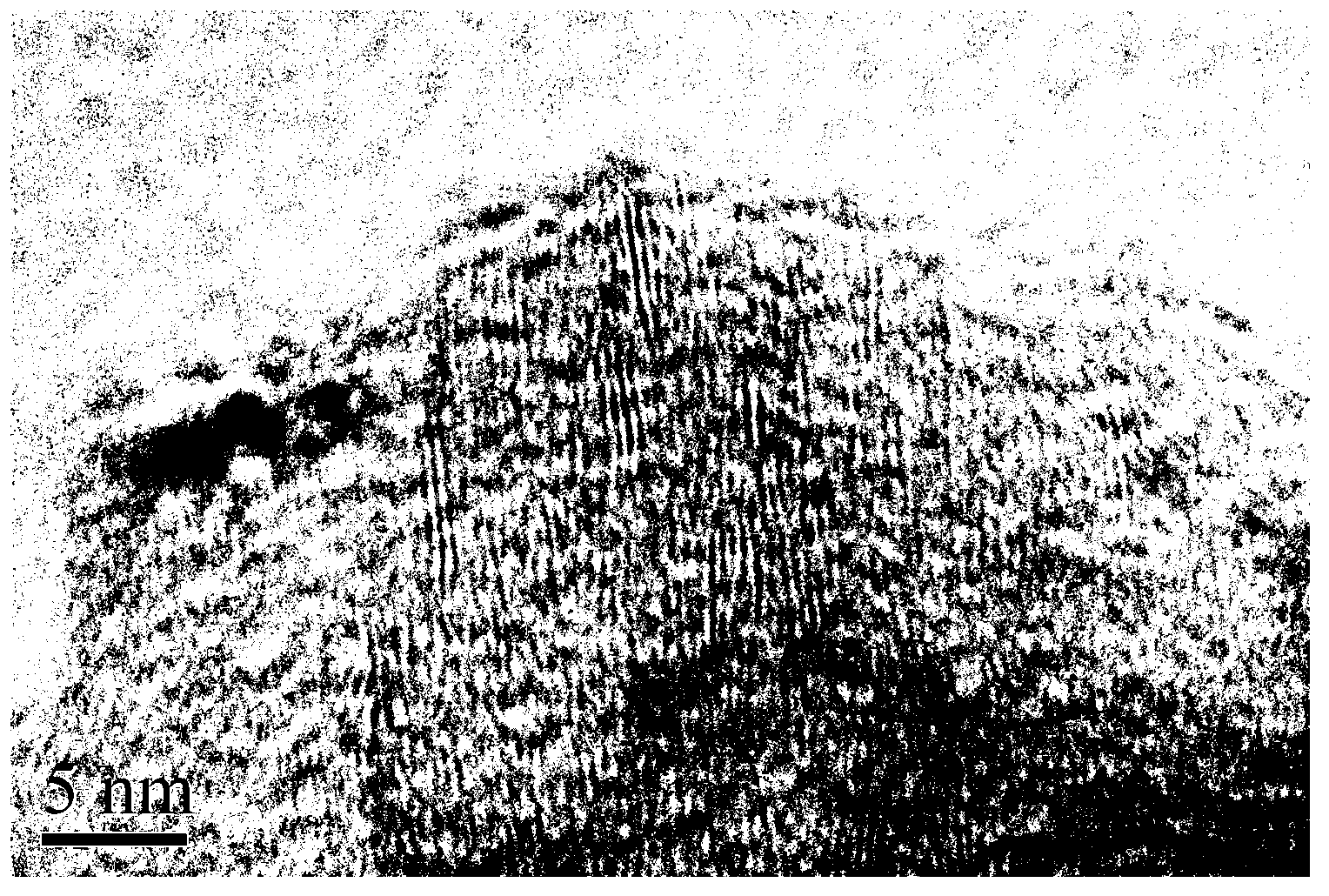

[0069] Use 0.3×5mm magnetic stainless steel needle 300g, 300-mesh graphite powder 10g, put it into a 500ml quartz glass container, turn on the rotating magnetic field, the magnetic field conversion frequency is 1800r / min, the magnetic induction intensity at the bottom of the grinding container is 0.15T, stop after 16h, from Take out the graphite and steel needles from the container, and magnetically separate them to obtain a graphite nanoflake-graphene mixture, mix them with 2000ml N-methylpyrrolidone and graphite nanoflakes-graphene, settle for 48 hours, take the upper liquid, and pass through 3000r / min Centrifuge for 0.5 h, take the supernatant, and freeze-dry to obtain loose single-layer or multi-layer graphene dry powder. The high-resolution transmission electron microscopy (HRTEM) image of the obtained graphene powder is as follows: image 3 , the Raman spectrum (RAMAN) of the obtained graphene is as Figure 4 , X-ray diffraction (XRD) patterns of graphite raw material a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com