Synthesis method of water dispersible polyaniline/graphene composite material

A technology of composite materials and graphene, which is applied in the field of preparation of polyaniline/graphene composite materials, can solve problems such as poor processing performance, easy accumulation and agglomeration, and difficult application, so as to achieve good processing performance, avoid agglomeration, good application prospects and The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

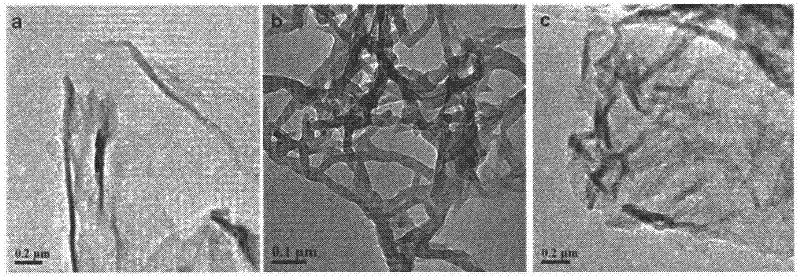

Image

Examples

Embodiment 1

[0017] 1. Preparation of graphene by heating reduction with hydrazine

[0018] Put 1.0g of graphite oxide into a 500mL round-bottomed flask, add 250mL of distilled water, at this time an inhomogeneous brown dispersed phase appears, ultrasonically vibrate for 30min in an ultrasonic disperser; add hydrazine hydrate (10mL), and release the solution Heat the reaction at 100°C in an oil bath for 24 h; then alternately wash with distilled water and absolute ethanol and centrifuge for more than 10 times.

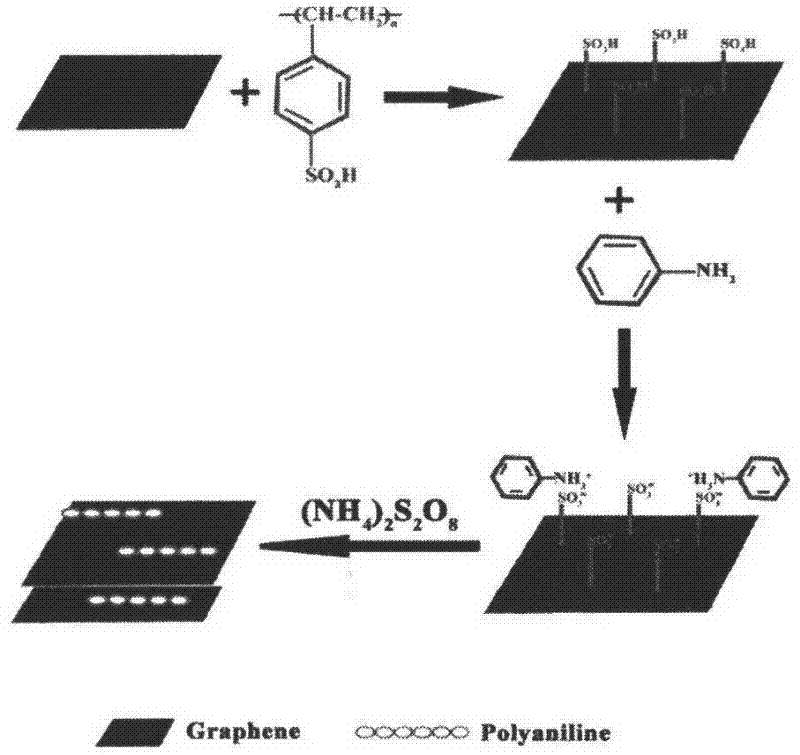

[0019] 2. Preparation of water-dispersed polyaniline / graphene composites containing 30wt% graphene

[0020] Put 100 mg of graphene in a beaker, add 1 g of polystyrenesulfonic acid, 5 mL of DMF and 20 mL of water, and stir to obtain a graphene dispersion. Add 0.23 g of aniline monomer to the graphene dispersion, pass nitrogen gas for about 30 minutes, and stir in an ice bath. Then add 0.57g of ammonium persulfate to the mixture, and react in ice bath for 6h. After centrifuging, w...

Embodiment 2

[0022] 2. prepare graphene (GR) by hydrazine heating reduction: same as embodiment 1 step 2

[0023] 3. Preparation of water-dispersed polyaniline / graphene composite material containing 50wt% graphene

[0024] Put 100 mg of graphene in a beaker, add 1 g of polyvinylpyrrolidone, 3 mL of DMSO and 20 mL of water, and stir to obtain a graphene dispersion. Add 0.10 g of aniline monomer to the graphene dispersion, pass nitrogen gas for about 30 minutes, and stir in an ice bath. Then add 0.25g of ammonium persulfate to the mixture, and react in ice bath for 6h. After centrifuging, washing, and dissolving in water, a water-dispersed polyaniline / graphene composite material can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com