Preparation method of graphene oxide/bacterial cellulose antibacterial compound material

A technology of bacterial cellulose and composite materials, applied in the field of composite materials, can solve problems such as affecting application and development, no antibacterial properties, etc., and achieve the effects of superior antibacterial properties, easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

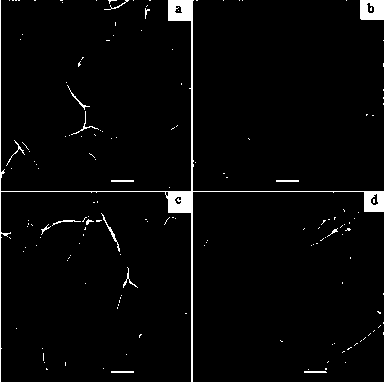

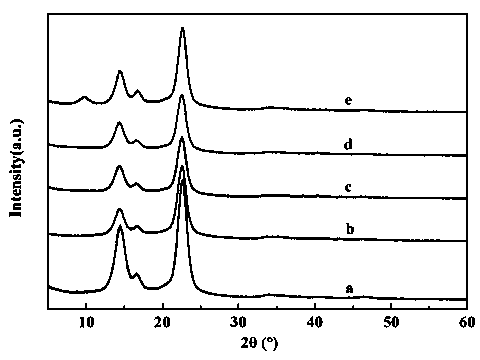

Image

Examples

Embodiment 1

[0027] Yeast extract (5 g / L), glucose (5 g / L), potassium dihydrogen phosphate (1 g / L), magnesium sulfate heptahydrate (15 g / L) and peptone (5 g / L) were prepared into 100 mL of seed culture base and 200mL of fermentation medium without adjusting the pH. Put the seed medium and fermentation medium into a sterilizing pot at a temperature of 121° C. and a pressure of 0.1 MPa, and sterilize for 20 minutes. After cooling the culture medium, add ethanol (20 mL / L). The activated Acetobacter xylinum was inoculated into the seed medium, and cultured in a shaker at 30° C. and 160 rpm / min for 24 h. According to the inoculum amount of 6% (volume ratio, all can be in the range of 5-10%), the seed culture liquid is inoculated into the fermentation medium, fully shaken to make it mix evenly, and then cultured at 30±2°C for 1-2 weeks, A milky white bacterial cellulose film was obtained. Rinse the residues on the surface of bacterial cellulose with deionized water, soak in 0.1M NaOH solution,...

Embodiment 2

[0029] The method is the same as in Example 1, except that the bacterial cellulose homogeneous suspension and the graphene oxide solution are mixed at a volume ratio of 100:1, stirred evenly and ultrasonically treated to form a homogeneous mixture. The mixture was subjected to -0.1MPa negative pressure filtration, and finally vacuum freeze-dried at -80°C to obtain a graphene oxide / bacterial cellulose composite material.

Embodiment 3

[0031] The method is the same as in Example 1, except that the bacterial cellulose homogeneous suspension is mixed with the graphene oxide solution at a volume ratio of 200:3, stirred evenly, and ultrasonically treated to form a homogeneous mixture. The mixture was subjected to -0.1MPa negative pressure filtration, and finally vacuum freeze-dried at -80°C to obtain a graphene oxide / bacterial cellulose composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| percent by volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com