Preparation method of graphene oxide and preparation method of graphene

A technology of graphene and graphite, which is applied in the field of graphene, can solve the problems of complex process, cumbersome operation, and difficulty in preparing large particle size graphene oxide, and achieve the effects of simple process, expanded application, and sufficient oxidation peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a kind of preparation method of graphene oxide, comprises the following steps:

[0030] Mix graphite, concentrated acid and strong oxidant evenly, and react in a closed environment at 80°C to 130°C to obtain graphene oxide.

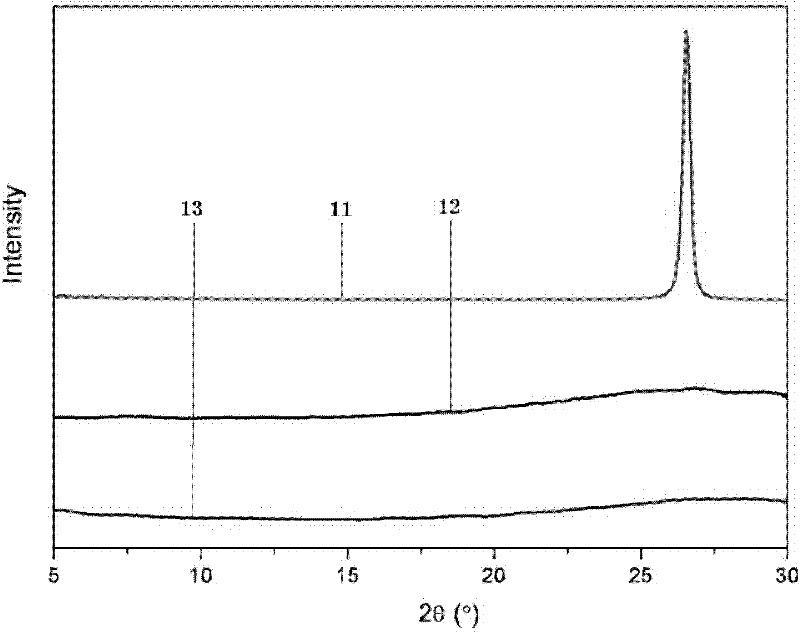

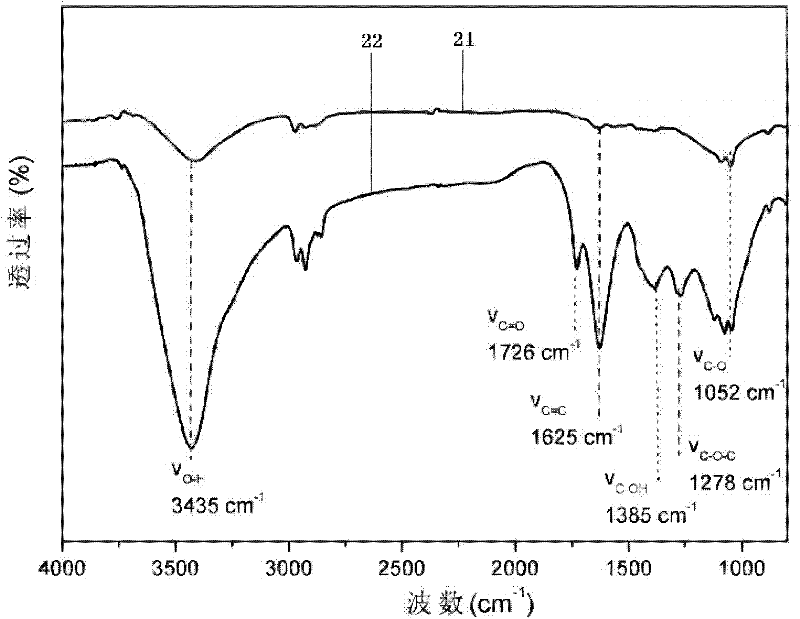

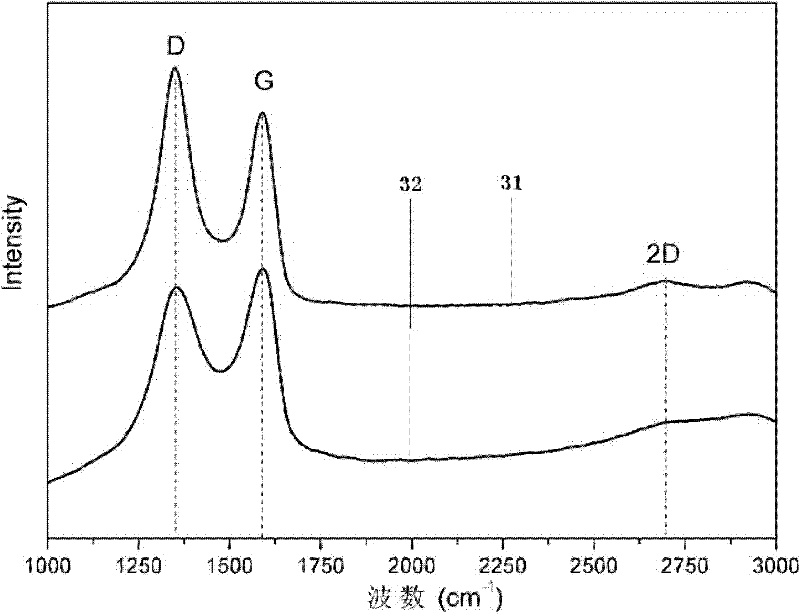

[0031] The invention uses graphite as a raw material, oxidizes it with a strong oxidant under the conditions of concentrated acid, high temperature and airtightness, and exfoliates the graphite into a single-sheet structure to obtain graphene oxide.

[0032] The present invention has no special restrictions on the graphite, which can be natural flake graphite or pure graphite powder; when the graphite is natural flake graphite, the present invention has no special restrictions on the particle size of the natural flake graphite, preferably 20 mesh- 800 mesh, more preferably 30-200 mesh; when the graphite is pure graphite powder, it is preferably analytically pure graphite powder or spectrally pure graphite powder.

[0033] Ac...

Embodiment 1

[0058] Cool 20g of 50-mesh natural flake graphite, 50g of sodium nitrate, 100g of potassium permanganate and 800g of concentrated sulfuric acid with a mass concentration of 98% at 2°C to 4°C for 1 hour, and then add them to the polytetrafluoroethylene In the ethylene reaction kettle, stir slowly for 1min, cover the lid tightly, let it stand at 2°C to 4°C for 1h, then react in an oven at 100°C for 1h; Take out, slowly pour the reaction mixture into 6L of deionized water, stir evenly, add 90mL of hydrogen peroxide aqueous solution with a mass concentration of 20%, stir until the suspension is bright yellow, suction filter and wash the suspension Graphene oxide is obtained after the pH value is 7;

[0059] The graphene oxide was added to 5L of deionized water, 25g of hydrazine hydrate with a mass concentration of 85% was added under stirring conditions, the temperature was raised to 95°C for 15h, and the obtained reaction mixture was cooled, settled, suction filtered, and used to...

Embodiment 2

[0067] Cool 2g of 200-mesh natural flake graphite, 16g of potassium chlorate and 40g of concentrated nitric acid at 1°C to 3°C for 1 hour respectively, then add them into a polytetrafluoroethylene reaction kettle placed in a stainless steel kettle shell, stir slowly for 0.5min, and cover the kettle tightly Cover, let stand at 1°C to 3°C for 0.5h, then react in an oven at 90°C for 1h; after fully cooling, take the polytetrafluoroethylene reactor out of the stainless steel shell, and slowly pour the reaction mixture into 3L In deionized water, stir evenly, suction filter, and wash until the pH value is 7 to obtain graphene oxide;

[0068] The graphene oxide was added to 0.4L deionized water, 2.4g of hydrazine hydrate with a mass concentration of 85% was added under stirring conditions, the temperature was raised to 95°C for 15h, and the obtained reaction mixture was cooled, settled, suction filtered, Graphene was obtained after washing with deionized water until the pH value was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com