Preparation method and application of conductive ink based on metal nanowire and graphene oxide

A technology of metal nanowires and conductive inks, applied in the direction of metal pattern materials, inks, applications, etc., can solve problems such as unsatisfactory conductivity, conductive layer fracture, and high sintering temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) Weigh 0.16g of graphene oxide prepared by a chemical method and place it in a beaker, add 80ml of deionized water, and ultrasonically obtain a 2mg / ml graphene oxide dispersion for 30 minutes, and use 1mol / L NaHCO 3 The solution adjusts the pH value of the graphene oxide dispersion to 6.5.

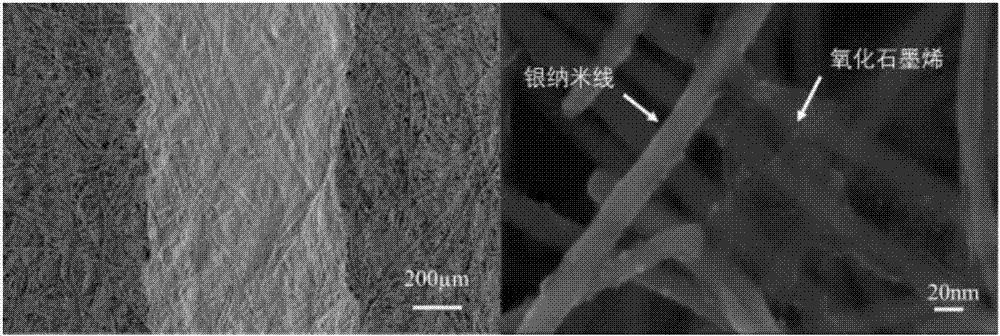

[0052] (2) Weigh 6ml of silver nanowire dispersion (10mg / ml) in a reagent bottle, add 10mg of the graphene oxide dispersion obtained in step (1), after the two are mixed, coagulation occurs, and suction filtration with a microporous membrane , washed several times with deionized water to obtain a composite of silver nanowires and graphene oxide.

[0053] (3) Weigh 0.1g of auxiliary dispersant PVP and 0.02g of defoamer BYK-028 into a beaker, add 9.88g of deionized water, and ultrasonically disperse to obtain an additive solution.

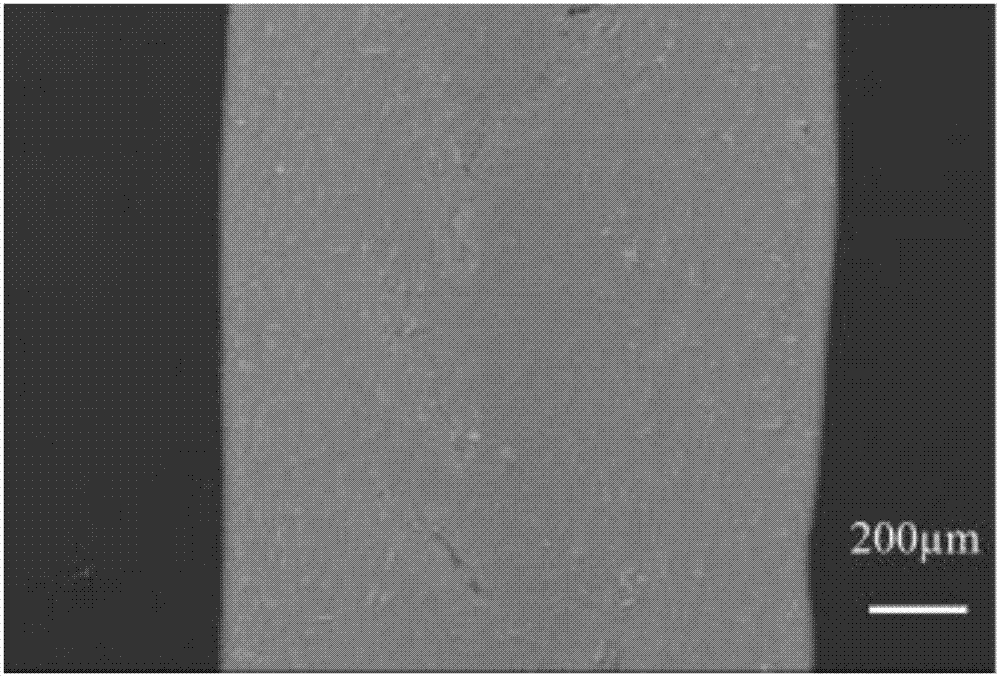

[0054] (4) Disperse the composite of silver nanowires and graphene oxide in 1.5 ml of the additive prepared in step (3), ultrasonicate and vibrate to ...

Embodiment 2

[0057] (1) Weigh 0.16g of graphene oxide prepared by a chemical method and place it in a beaker, add 80ml of deionized water, and ultrasonically obtain a 2mg / ml graphene oxide dispersion for 30 minutes, and use 1mol / L NaHCO 3 The solution adjusts the pH value of the graphene oxide dispersion to 6.5.

[0058] (2) Weigh 6ml of silver nanowire dispersion (10mg / ml) in a reagent bottle, add 10mg of the graphene oxide dispersion obtained in step (1), after the two are mixed, coagulation occurs, and suction filtration with a microporous membrane , washed several times with deionized water to obtain a composite of silver nanowires and graphene oxide.

[0059] (3) Weigh 0.1g auxiliary dispersant PVP, 0.02g defoamer BASF FoamstarMO2170, 0.05g surfactant Add 9.83g of deionized water to FC-300 in a beaker, and ultrasonically disperse to obtain an additive solution.

[0060] (4) Disperse the composite of silver nanowires and graphene oxide in 1.5 ml of the additive prepared in step (3),...

Embodiment 3

[0065] (1) Weigh 0.16g of graphene oxide prepared by a chemical method and place it in a beaker, add 80ml of deionized water, and ultrasonically obtain a 2mg / ml graphene oxide dispersion for 30 minutes, and use 1mol / L NaHCO 3 The solution adjusts the pH value of the graphene oxide dispersion to 6.5.

[0066] (2) Weigh 6ml of silver nanowire dispersion (10mg / ml) in a reagent bottle, add 5mg of the graphene oxide dispersion obtained in step (1), after the two are mixed, coagulation occurs, and suction filtration with a microporous membrane , washed several times with deionized water to obtain a composite of silver nanowires and graphene oxide.

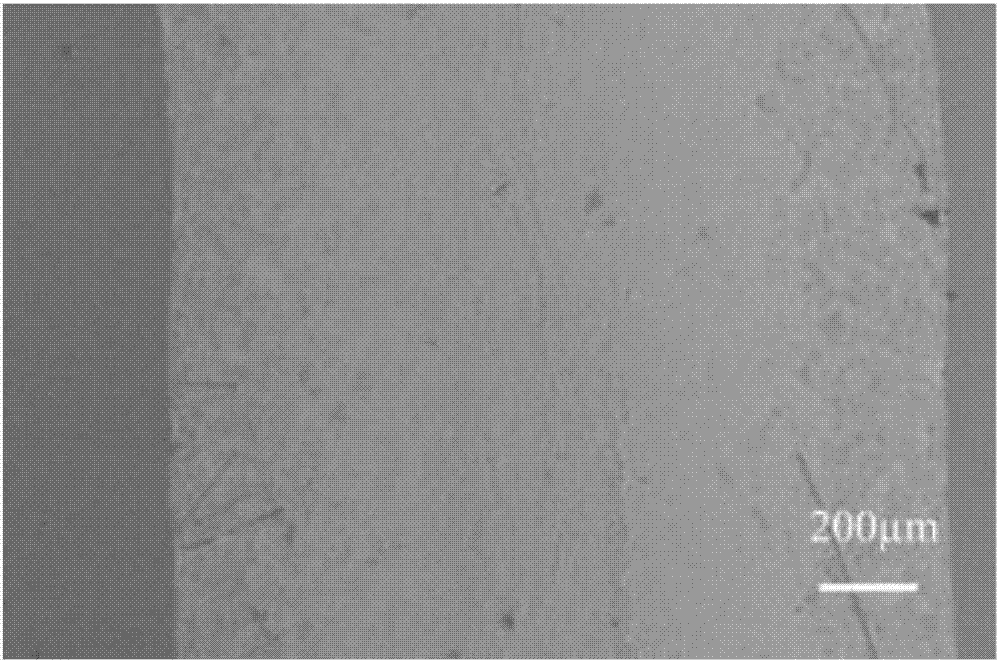

[0067] (3) Weigh 0.2g thickener Gel 0435, 0.1g auxiliary dispersant Gen 0451, 0.01g defoamer BYK-028, 0.05g surfactant Add 9.83g of deionized water to N321 in a beaker, and ultrasonically disperse to obtain an additive solution.

[0068] (4) Disperse the composite of silver nanowires and graphene oxide in 1.5 ml of the additive pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com