Composite intensified heat dissipation coating containing graphene or graphene oxide and preparation method of coating

A heat-dissipating coating and graphene technology, applied in polyester coatings, coatings, etc., can solve the problem of high thermal conductivity, and achieve the effects of large specific surface area, good film formation and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

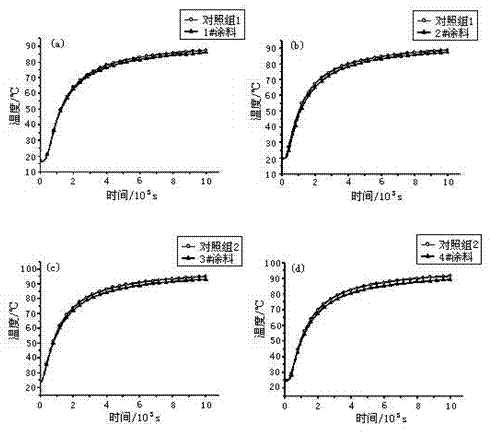

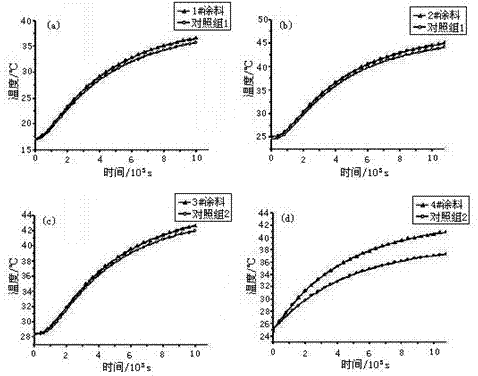

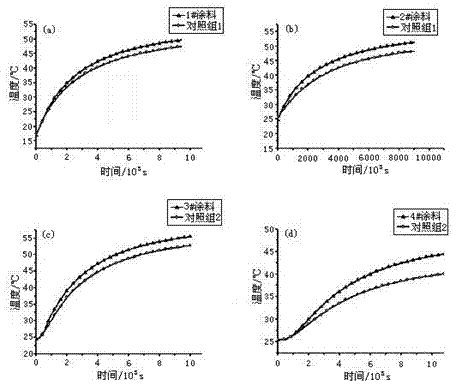

Examples

Embodiment 1

[0049] 1. Weigh 20g of tourmaline and 64g of iron oxide (Fe 2 o 3 ), 12g of manganese oxide (MnO 2 ), 4g of cobalt oxide (Co 2 o 3 ), according to the mass ratio of material: ball: water = 1:3:1, put it into a ball mill tank (1 liter ball mill tank, the ball is zirconia with a diameter of 1 cm), and ball mill at a speed of 1100r / min for 1 hour;

[0050] 2. Put the ball-milled slurry into a Buchner funnel for suction filtration, dry and grind the obtained filter cake; put the ground mixture into a muffle furnace, heat-treat at 800°C for 3 hours, and then Cool the furnace to room temperature;

[0051] 3. Put the heat-treated mixture into a ball mill for 3 hours, dry and grind to obtain tourmaline-transition metal oxide composite powder (DF powder for short);

[0052] 4. Weigh 30g of DF powder and 2g of titanate coupling agent (NDZ-201, the same as other embodiments of the present invention) into a 1000ml round bottom flask, add toluene until the flask is submerged in DF pow...

Embodiment 2

[0057] 1. Weigh 20g of tourmaline and 64g of iron oxide (Fe 2 o 3 ), 12g of manganese oxide (MnO 2 ), 4g of cobalt oxide (Co 2 o 3 ), according to the mass ratio of material: ball: water = 1:3:1, put it into the ball mill tank, and ball mill at a speed of 1100r / min for 1 hour;

[0058] 2. Put the ball-milled slurry into a Buchner funnel for suction filtration, dry and grind the obtained filter cake; put the ground mixture into a muffle furnace, heat-treat at 800°C for 3 hours, and then Cool the furnace to room temperature;

[0059] 3. Put the heat-treated mixture into a ball mill for 3 hours, dry and grind to obtain tourmaline-transition metal oxide composite powder (DF powder for short);

[0060] 4. Weigh 30g of DF powder and 2g of titanate coupling agent into a 1000ml round bottom flask, add toluene until the flask is submerged in DF powder, put the flask into an electric heating mantle for reflux modification for 4 hours;

[0061] 5. Recover the toluene in the reactio...

Embodiment 3

[0065] Steps 1 to 3 are the same as in Embodiment 1, and then continue with the following steps:

[0066] 4. Weigh 3g of graphene oxide, add 30ml of deionized water to ultrasonically disperse to obtain graphite oxide suspension, add it into a round bottom flask, weigh 30g of DF powder into the round bottom flask, add ethanol until 1 / 3 of the flask is immersed in DF Put the flask into the electric heating mantle to reflux for 3 hours, so that the graphene oxide is wrapped on the DF powder, filter, dry, and grind to obtain the DF powder (referred to as GODF powder) coated with graphene oxide on the surface;

[0067] 5. Weigh 30g of GODF powder and 2g of titanate coupling agent into a 1000ml round bottom flask, add toluene until the flask is submerged in GODF powder, put the flask into an electric heating mantle for reflux modification for 4 hours;

[0068] 6. Recover the toluene in the reaction solution with a rotary evaporator;

[0069] 7. Take out the modified filler, dry, di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com