Method for preparing reduced graphene oxide/ferroferric oxide nano-grade wave-absorbing materials

A nano wave-absorbing material, the technology of ferroferric oxide, which is applied in the direction of chemical instruments and methods, and other chemical processes, can solve the problems of harsh preparation conditions, difficult large-scale production, and poor performance of composite materials, and achieve large-scale The effect of production, wide absorption frequency and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Prepare a GO aqueous solution with a concentration of 0.5mg / ml, and a 1mol / L NaOH aqueous solution for later use;

[0029] 2. According to the mass ratio of GO:FeCl 2 4H 2 O:FeCl 3 ·6H 2 O=1:0.65:0.88 Weigh 65mg FeCl 2 4H 2 O and 88mg FeCl 3 ·6H 2 O, added to 200ml GO aqueous solution, heated in a water bath to 50°C for 10min, added NaOH solution dropwise to adjust the pH of the mixture to 11, and heated the mixture at 70°C for 3h;

[0030] 3. According to the mass ratio of GO: NaBH 4 =1:6 weigh 600mg NaBH 4 Dissolve in 50ml of water, drop into the mixture, and heat at 80°C for 1 hour;

[0031] 4. Alternately wash with deionized water and absolute ethanol until pH = 7, centrifuge or filter, and then vacuum-dry at 60°C to obtain a black powder that is RGO-Fe 3 o 4 composite material.

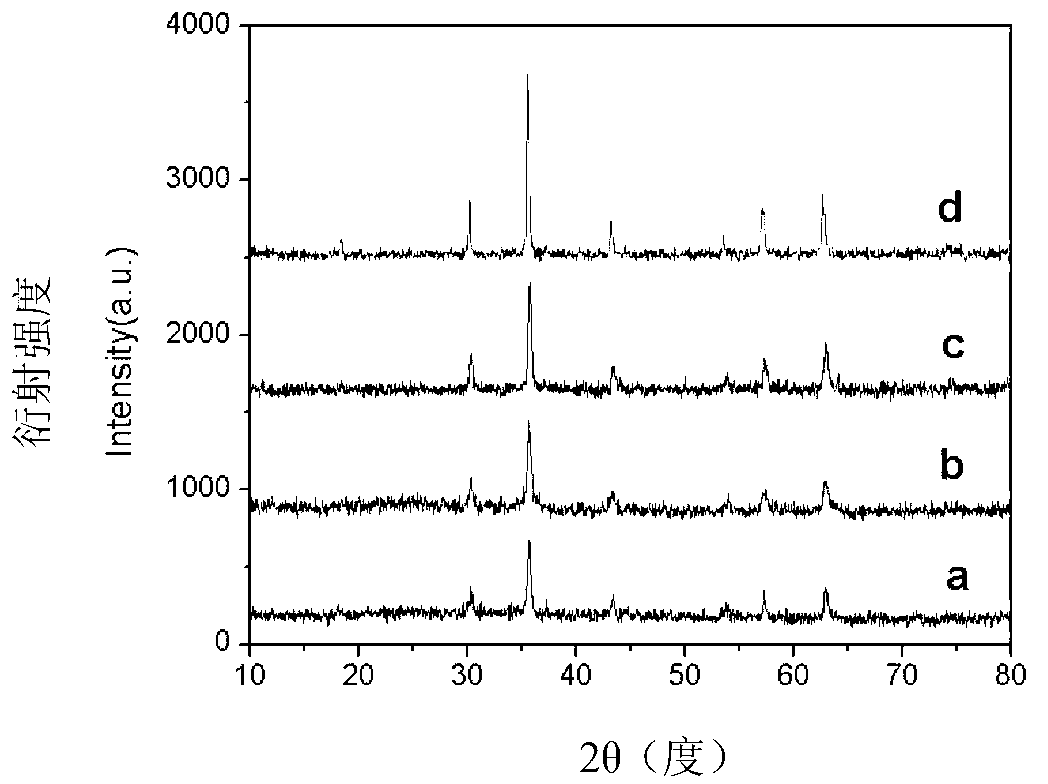

[0032] The XRD spectrogram of embodiment 1 product sees figure 1 (a). Mix the powder product in Example 1 and solid paraffin evenly according to the mass ratio of 1:1, pre...

Embodiment 2

[0034] 1. Prepare a GO aqueous solution with a concentration of 0.5mg / ml, and a 1mol / L NaOH aqueous solution for later use;

[0035] 2. According to the mass ratio of GO:FeCl 2 4H 2 O:FeCl 3 ·6H 2 O=1:1.29:1.76 Weigh 129mg FeCl 2 4H2 O and 176 mg FeCl 3 ·6H 2 O, added to 200ml GO aqueous solution, heated in a water bath to 50°C for 10min, added NaOH solution dropwise to adjust the pH of the mixture to 11, and heated the mixture at 70°C for 3h;

[0036] 3. According to the mass ratio of GO: NaBH 4 =1:6 weigh 600mg NaBH 4 Dissolve in 50ml of water, drop into the mixture, and heat at 80°C for 1 hour;

[0037] 4. Alternately wash with deionized water and absolute ethanol until pH = 7, centrifuge or filter, and then vacuum-dry at 60°C to obtain a black powder that is RGO-Fe 3 o 4 composite material.

[0038] The XRD spectrum pattern of embodiment 2 product sees figure 1 (b). The powder product in Example 2 was uniformly mixed with solid paraffin at a mass ratio of 1:1 ...

Embodiment 3

[0040] 1. Prepare a GO aqueous solution with a concentration of 0.5mg / ml, and a 1mol / L NaOH aqueous solution for later use;

[0041] 2. According to the mass ratio of GO:FeCl 2 4H 2 O:FeCl 3 ·6H 2 O=1:2.58:3.52 weigh 258mg FeCl 2 4H 2 O and 352 mg FeCl 3 ·6H 2 O, added to 200ml GO aqueous solution, heated in a water bath to 50°C for 10min, added NaOH solution dropwise to adjust the pH of the mixture to 11, and heated the mixture at 70°C for 3h;

[0042] 3. According to the mass ratio of GO: NaBH 4 =1:6 weigh 600mg NaBH 4 Dissolve in 50ml of water, drop into the mixture, and heat at 80°C for 1 hour;

[0043] 4. Alternately wash with deionized water and absolute ethanol until pH = 7, centrifuge or filter, and then vacuum-dry at 60°C to obtain a black powder that is RGO-Fe 3 o 4 composite material.

[0044] The XRD spectrum pattern of embodiment 3 product sees figure 1 (c). The powder product in Example 3 was uniformly mixed with solid paraffin at a mass ratio of 1:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com