Bulk production process malfunction detection method based on multiple nucleus independent elements analyse

An independent meta-analysis, batch production technology, applied in the direction of analyzing materials, special data processing applications, comprehensive factory control, etc., can solve problems such as unsatisfactory performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

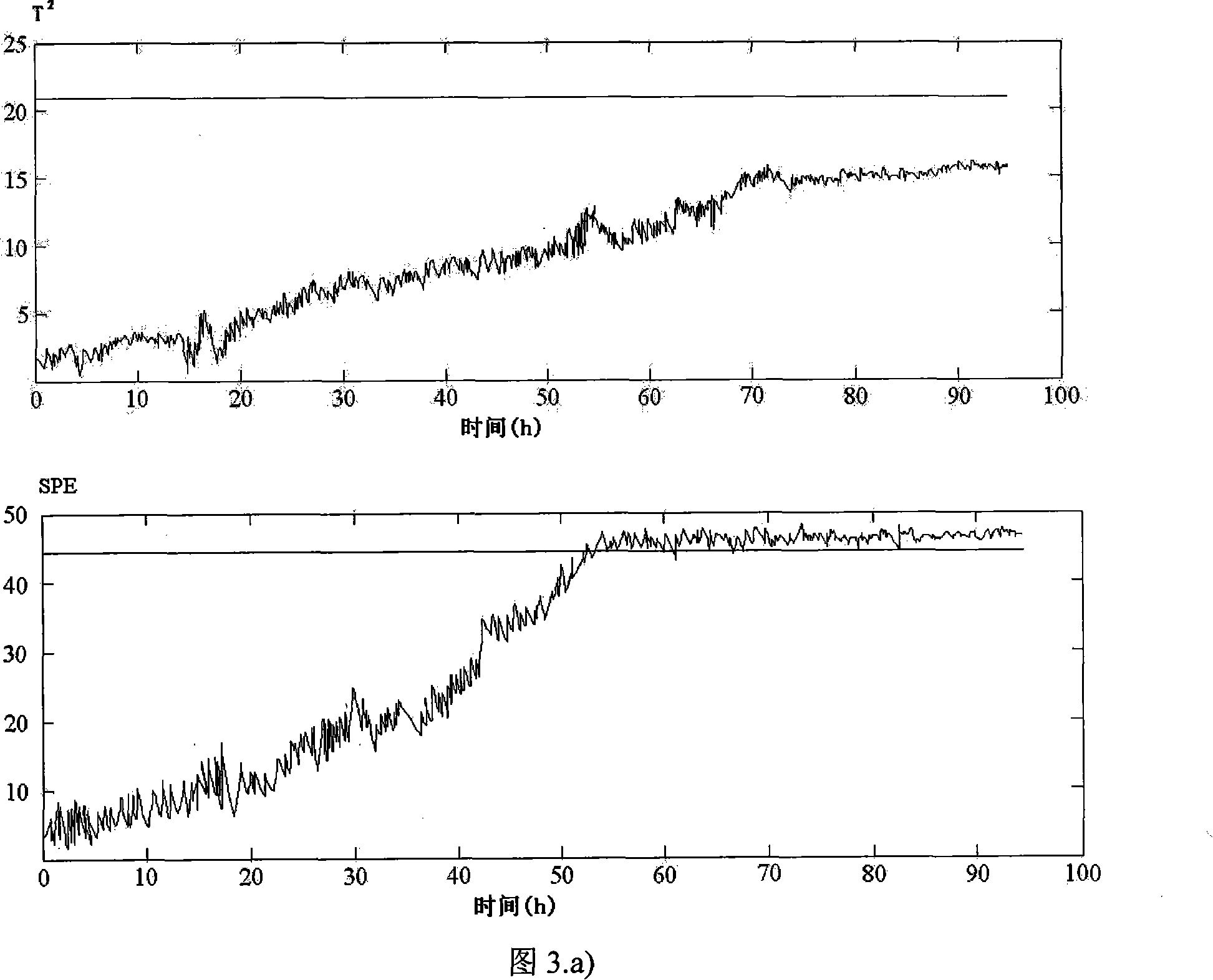

[0112] In this example, the MKICA method is applied to the monitoring of a well-known standard process—the fermentation of penicillin, as shown in Figure 2. The production process of penicillin has nonlinear characteristics. During the initial stages of penicillin fermentation, the necessary cellular material is placed in the fermenter. Add enzymes when the original enzymes are consumed by the microorganisms. Due to the influence of metabolic repressors, the low concentration of medium in the fermenter is an important guarantee for high fermentation rate. Glucose was continuously supplied at the start of fermentation. Introduce small changes to monitor how the penicillin fermentation process operates under fault conditions. The monitored variables are shown in Table 1. The duration of each batch was 400 hours, comprising a start phase of about 45 hours and a feedback phase of about 355 hours. Batches 1-14 are normal. There were faults in batches 15-30. In batch 15, a 10...

example 2

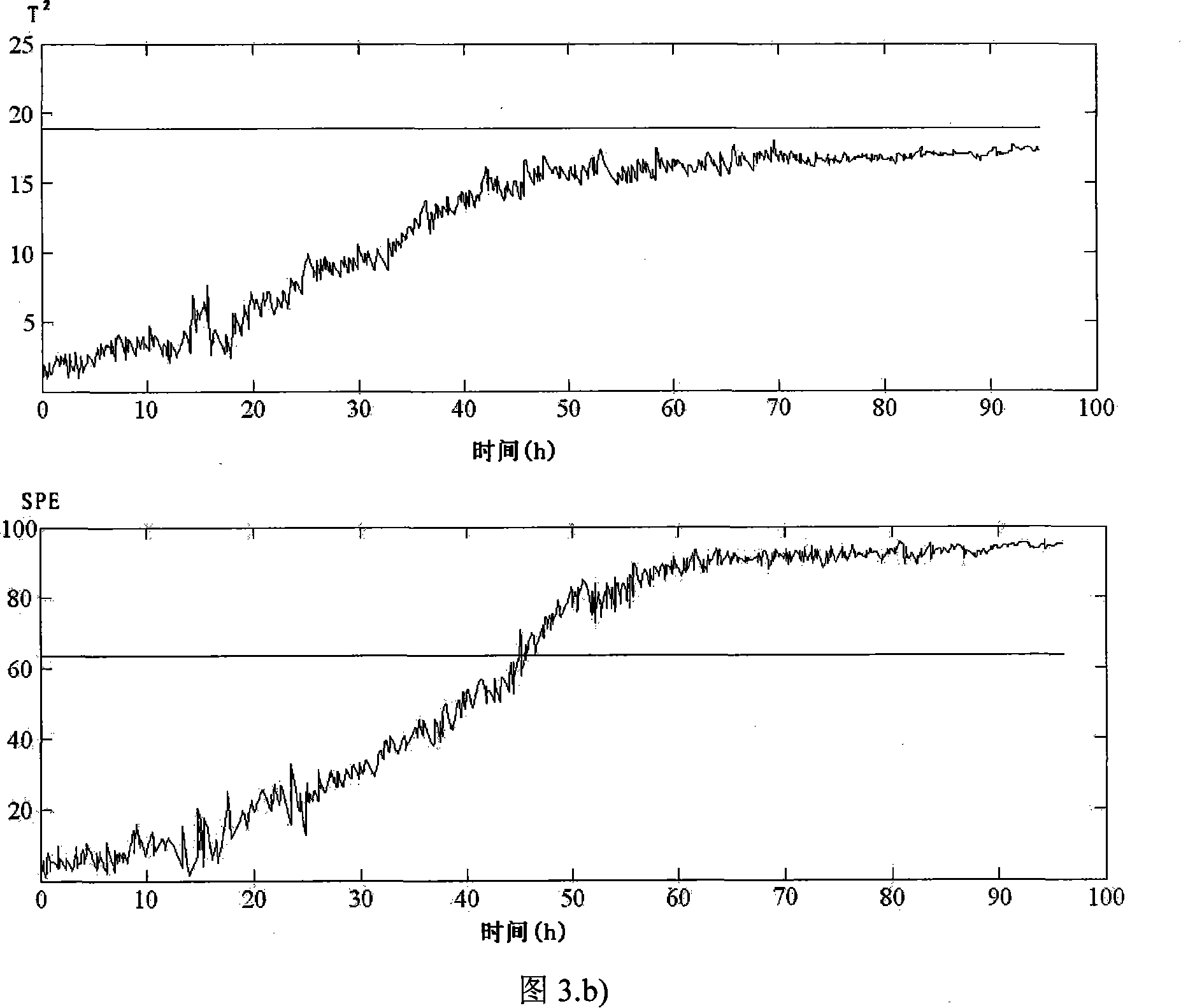

[0134] The method proposed by the present invention was applied to the data of the nosipeptide process. Nosiceptide is a bicyclic peptide antibiotic produced by Streptomyces. Its molecular formula is C 51 h 43 N 13 Q 12 S 6. Since Nosicapide can promote the growth of livestock and has no residue in livestock, it is mainly used as a feed additive. Some plants produce nosipeptide, which can be used as an additive. The production process of Nosicapide is a batch aerobic fermentation process which takes 96 hours. The process of cultivating the strains takes place in seed fermenters until the ferments reach the ripening stage. After reaching the ripening stage, the mature ferment is transferred to the final fermenter. The ferments in these fermenters are fermented in batch mode under normal conditions in order to optimize the synthesis of nosipeptide. During the fermentation process of nosipeptide, the online measurement variables include physical and chemical variables, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com