Modified copolyester slicer or fabric and method for making same

A copolyester and slicing technology, which is applied in the direction of single-component polyester rayon, can solve the problems of difficult polymerization reaction, low molecular weight, and decreased thermal stability of copolyester, and achieve low cost and super softness Feel, high shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

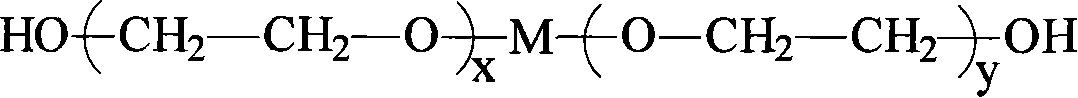

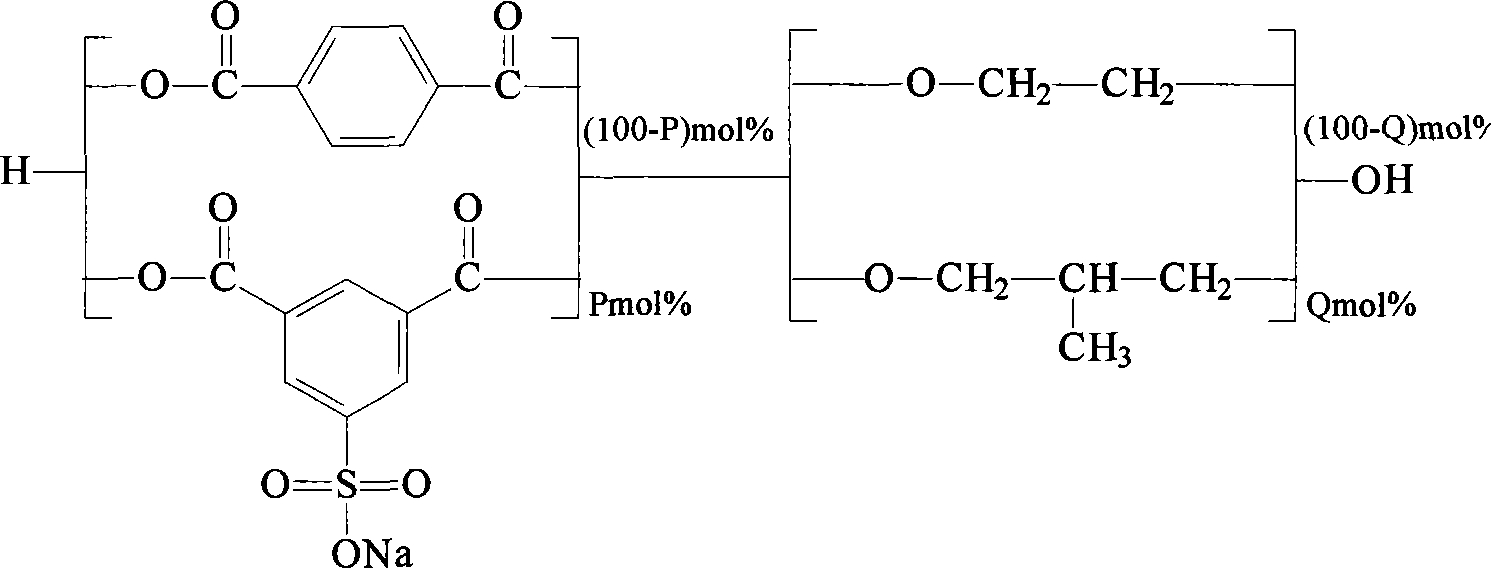

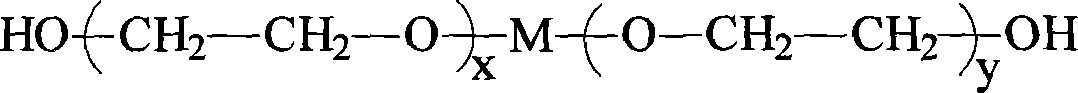

[0037] Using batch polymerization equipment, after mixing 2.117mol PTA, 3.403mol EG and 0.142mol MPD equivalent to 4mol% molar weight of EG and MPD mixed alcohol, they were added to the reaction system, and 0.01wt% antimony acetate catalyst and 0.02 Wt% triphenyl phosphate (relative to PTA), stirring at a temperature of 230~240°C and a pressure of 0.0~0.5Mpa for 1.5h, when the esterification reaction is completed, add SIPE equivalent to 3mol% of PTA to enter the polycondensation process stage, control the reaction temperature at 240~280°C, gradually reduce the pressure to vacuum degree <130pa, polycondensate for 2 hours, and finally obtain MCDP copolyester chips containing 4mol% of MPD units and 3mol% of SIPE units. The copolyester has an intrinsic viscosity of 0.512 and a melting point of 235°C.

Embodiment 2

[0039] Adopt batch-type polymerization equipment, add PTA 150kg, EG 70.6kg, and the MPD that is equivalent to EG and MPD mixed alcohol 10mol% molar weight, add the triphenyl phosphate of catalyst 0.01wt% antimony acetate catalyst and 0.02wt% (relative to PTA ), stirring for 3 hours at a temperature of 230~240°C and a pressure of 0.0~0.5Mpa. When the esterification reaction is over, add SIPE equivalent to 3mol% of PTA, control the reaction temperature at 240~280°C, and gradually reduce the pressure to vacuum <130pa, polycondensation for 4 hours, and MCDP copolyester chips containing 10 mol% of MPD units and 3 mol% of SIPE units were obtained. The copolyester has an intrinsic viscosity of 0.486 and a melting point of 214°C.

Embodiment 3

[0041] Adopt batch-type polymerization equipment, add PTA 150kg, EG 66.7kg, and the MPD that is equivalent to EG and MPD mixed alcohol 15mol% molar weight, add the triphenyl phosphate of catalyst 0.01wt% antimony acetate catalyst and 0.02wt% (relative to PTA ), stirring for 4 hours at a temperature of 230~240°C and a pressure of 0.0~0.5Mpa. When the esterification reaction is over, add 3mol% SIPE equivalent to PTA under a system of 0.1~0.01Mpa, and control the reaction temperature at 240~280°C , gradually decompressed to a vacuum degree <130pa, polycondensed for 4 hours, and prepared MCDP copolyester chips containing 15 mol% of MPD units and 3 mol% of SIPE units. The copolyester has an intrinsic viscosity of 0.476 and a melting point of 209°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com