Method for preparing photonic crystals through 3D (Three-Dimensional) printing

A photonic crystal and 3D printing technology, applied in the field of photonic crystal preparation, can solve the problems of high three-dimensional photonic crystal, difficult to prepare dielectric ratio, complicated process, etc., and achieve the effect of broad market prospect, short time consumption and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

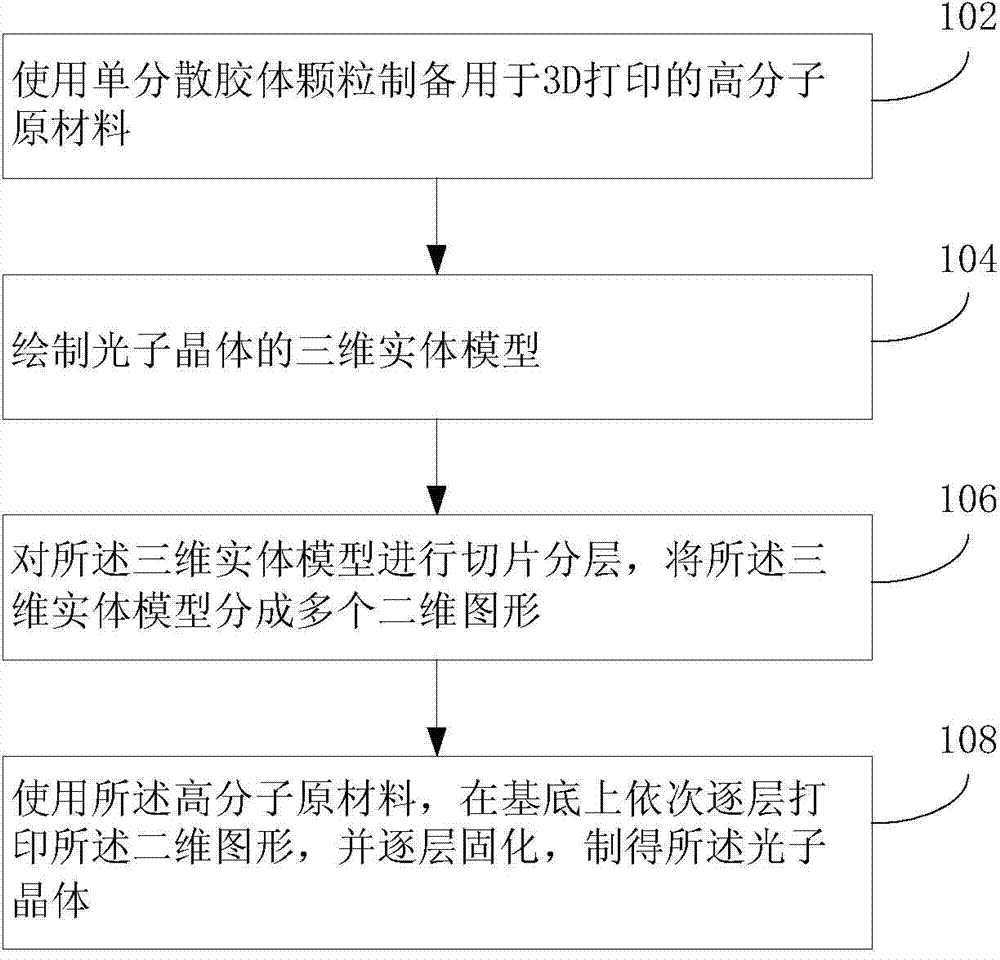

[0027] Such as figure 1 As shown, the method for preparing a photonic crystal by 3D printing of the present application, an implementation thereof, comprises the following steps:

[0028] Step 102: using monodisperse colloidal particles to produce polymer raw materials for 3D printing;

[0029] Step 104: drawing a three-dimensional solid model of the photonic crystal;

[0030] Step 106: slice and layer the 3D solid model, and divide the 3D solid model into multiple 2D graphics; the sequence of steps in this application is not unique, and step 102 can also be placed after this step.

[0031] Step 108: using polymer raw materials, printing two-dimensional graphics on the substrate layer by layer, and curing layer by layer to obtain photonic crystals.

[0032] The method for preparing a photonic crystal by 3D printing of the present application, another embodiment thereof, comprises the following steps:

[0033] Step 202: Disperse the monodisperse colloidal particles in a solu...

Embodiment

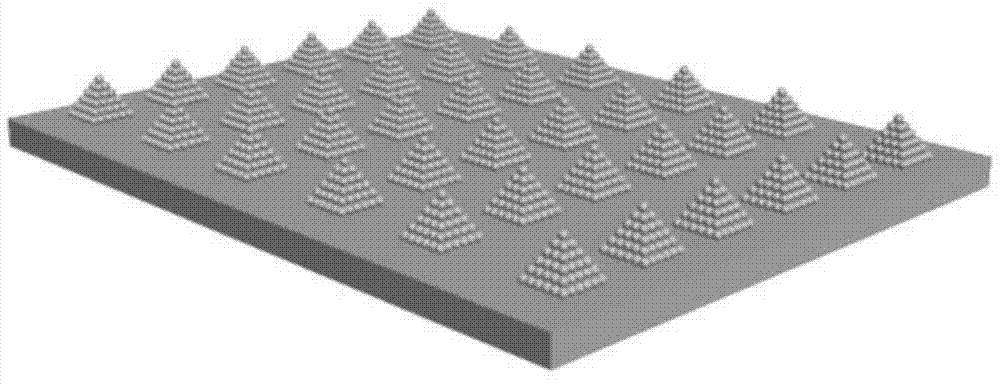

[0049] Production of polymer raw materials for 3D printing: Disperse silica colloidal particles with a concentration of 50% (w / v) in ethanol to obtain an ethanol suspension containing colloidal particles, take a certain amount of the suspension and ethoxylate Hydroxylated trimethylolpropane triacrylate (ETPTA) monomer and 2-hydroxy-2-methyl-1-phenyl-1-propanone (HMPP) UV curing agent are mixed so that the silica colloid in the mixture The concentration of particles is 30% (v / v), the concentration of ethoxylated trimethylolpropane triacrylate is 10% (v / v), 2-hydroxy-2-methyl-1-phenyl-1- The concentration of acetone was 1.5wt%, and then the mixed system was sonicated until structural color was produced.

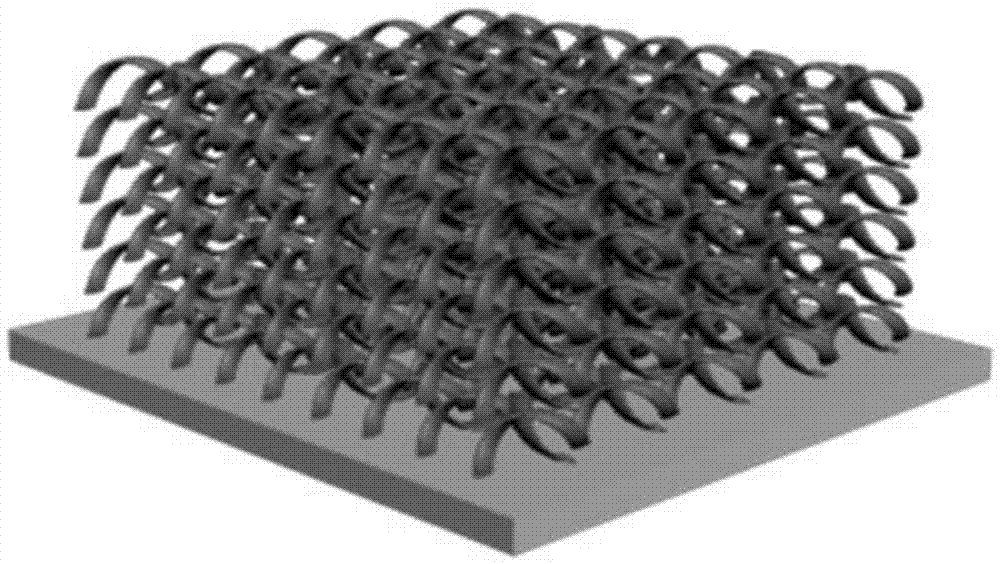

[0050] 3D printing: use the 3D Max drawing software to draw the three-dimensional solid model of the photonic crystal, and then layer the three-dimensional solid model into a series of two-dimensional graphics with equal thickness slices, with a thickness of 20 μm. Scan all tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com