Fermentation temperature management

a technology of fermentation temperature and management, applied in indirect heat exchangers, laminated elements, lighting and heating apparatuses, etc., can solve the problems of yeast dormant, difficult to consistently produce high-quality products, and negatively affecting the fermentation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

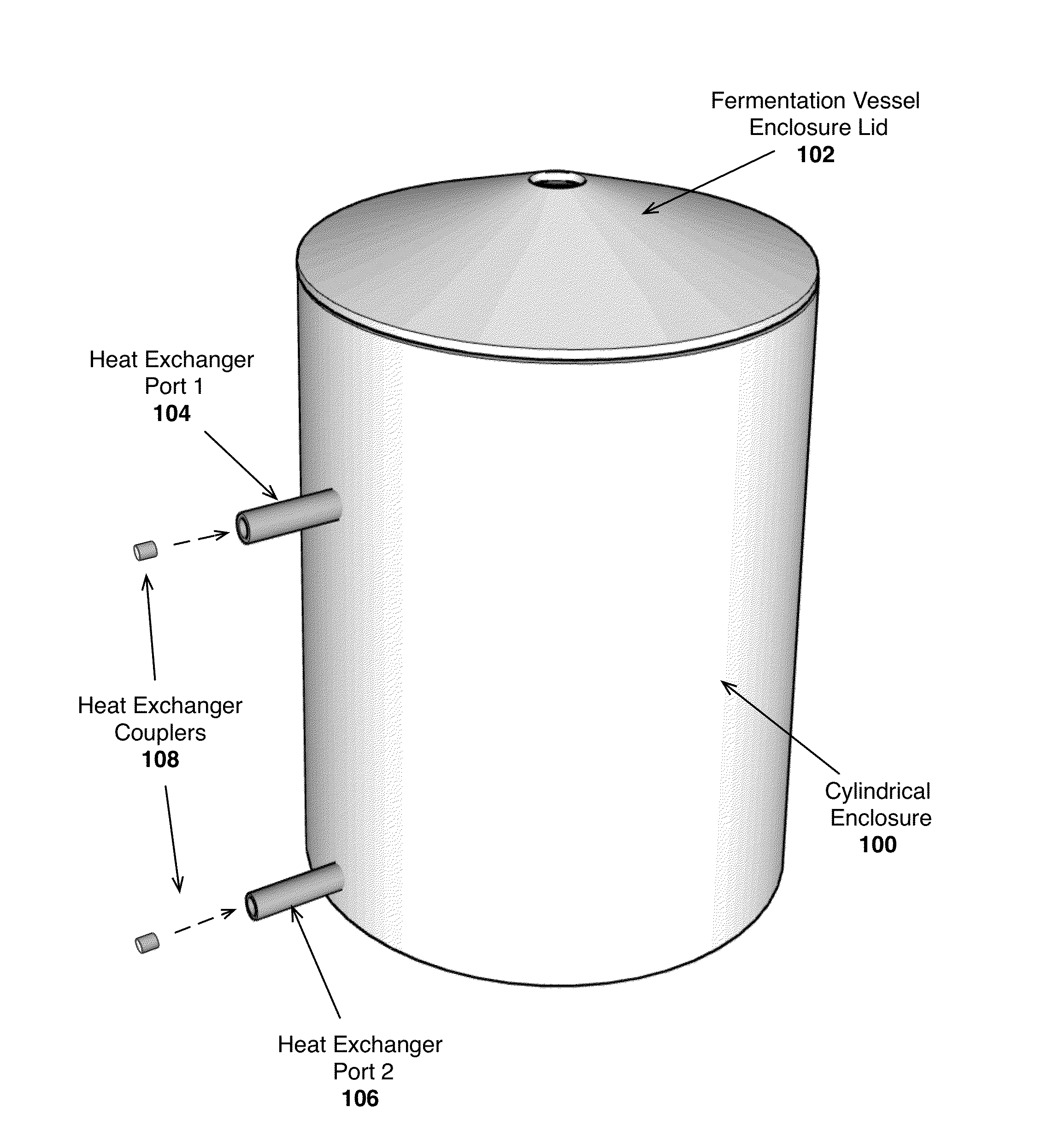

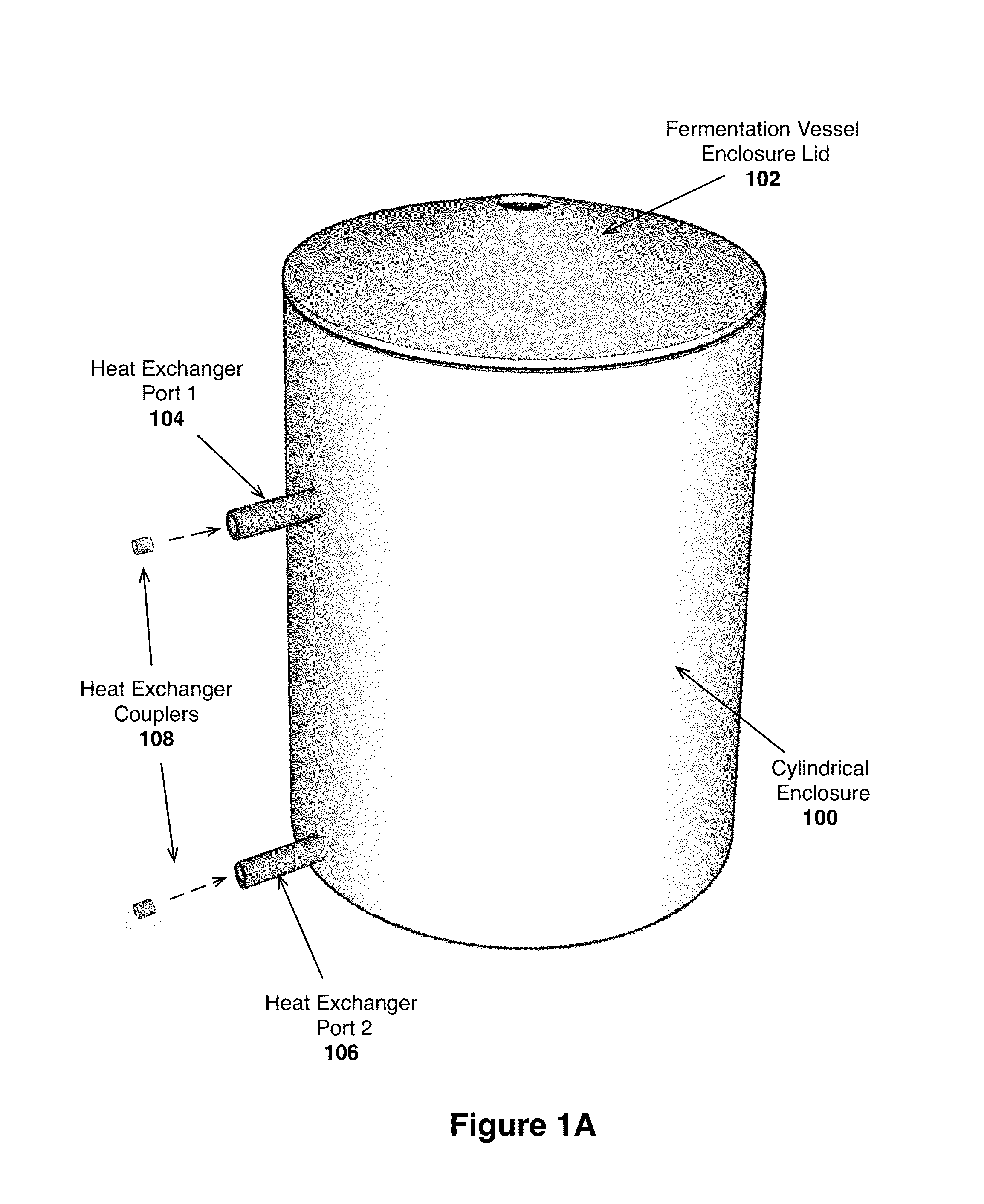

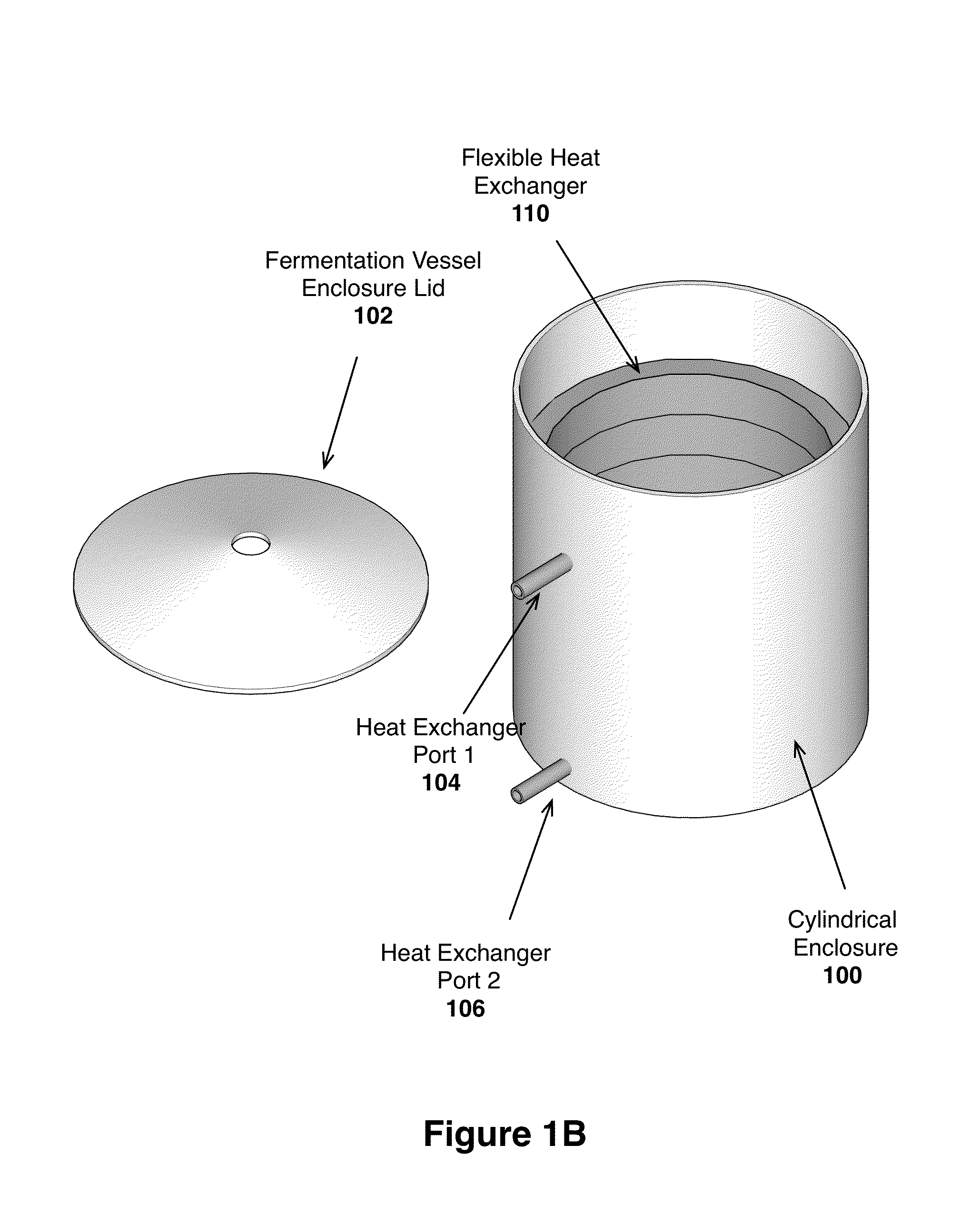

[0021]Various embodiments of a system and apparatus for temperature management in small scale brewing and fermentation operations are described. The various embodiments can be used to thermally manage (e.g., heat or cool) a human portable fermentation vessel to a temperature based on a pre-determined temperature profile, and maintain specific temperatures up to, or in excess of a 40° C. differential from ambient conditions. The ability to consistently control fermentation temperatures allows a beer brewer or wine maker to craft a particular product, and then repeatedly produce a consistent product by replicating the same temperature profile for subsequent batches, without requiring the use of expensive, high volume fermentation equipment.

[0022]In one embodiment, a portable assembly is provided that facilitates the thermal management of the contents of a 15-liter to 25-liter fermentation vessel during the process of beer and wine fermentation. The assembly includes an enclosure appar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com