Nano-silver conductive ink and conductive film prepared by employing same

A technology of conductive ink and conductive film, applied to the conductive layer on the insulating carrier, cable/conductor manufacturing, ink, etc., can solve the problems of increasing the difficulty and complexity of the manufacturing process, the detachment of the nanowire substrate, and the impact of product yield. Effective control of flatness, avoiding protection problems, and simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

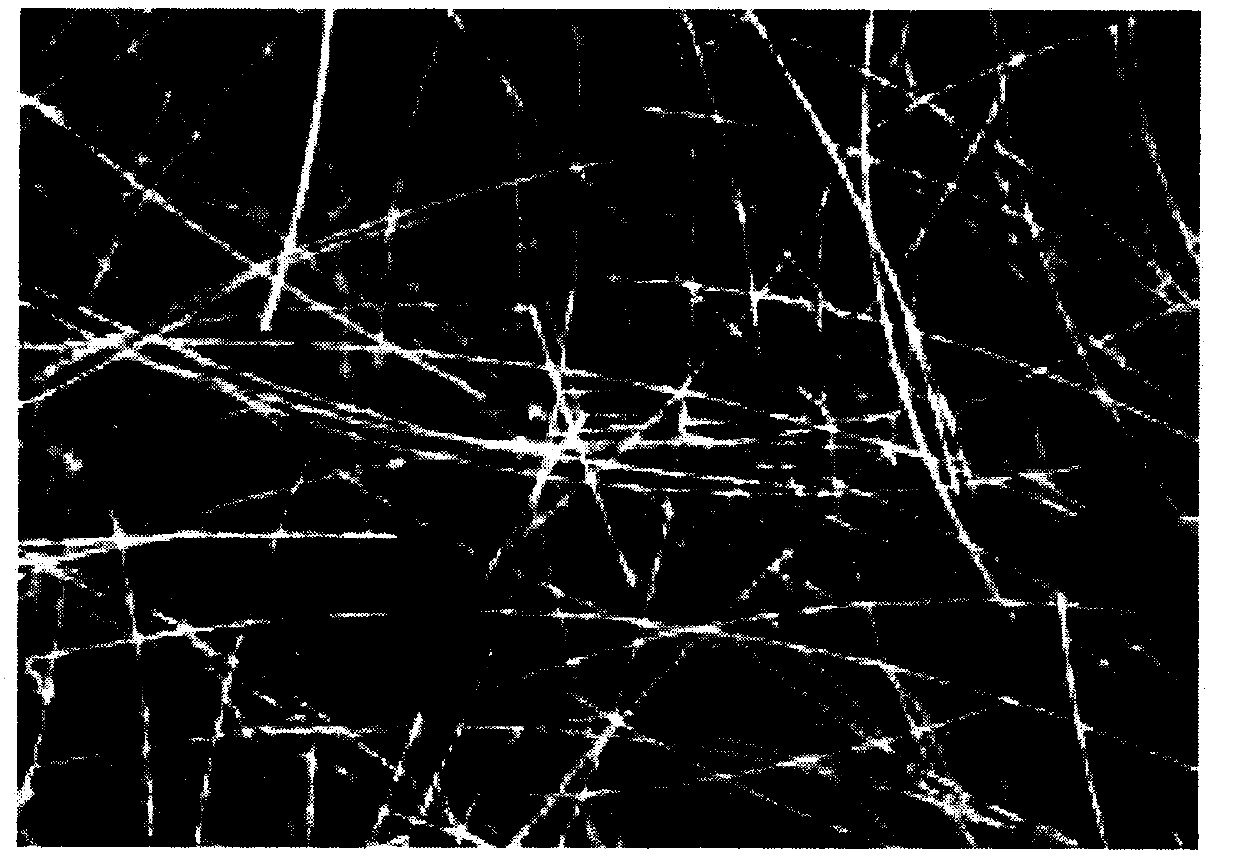

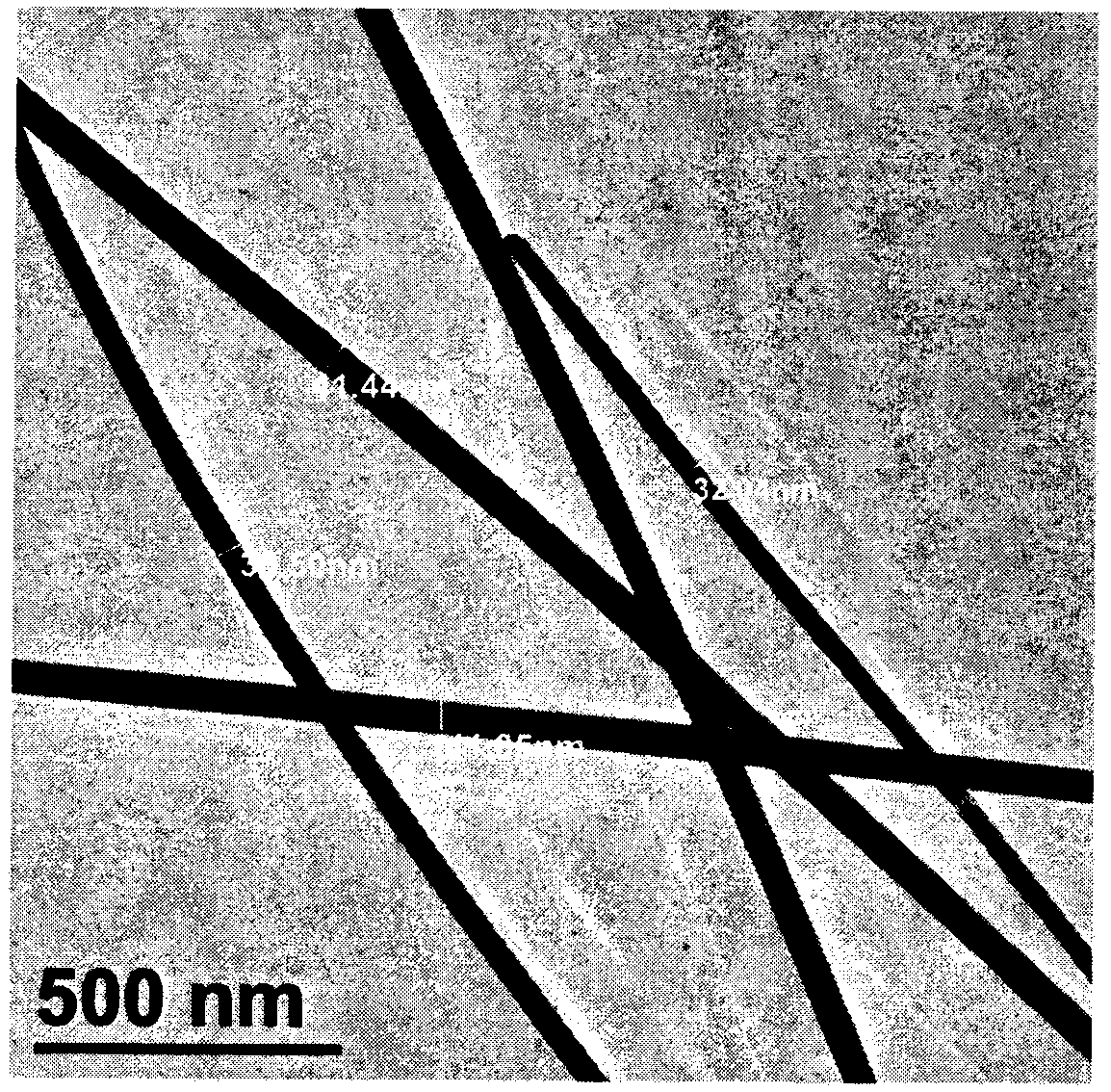

[0045] First, take 2.0g of SK polyester resin, dissolve 1g of cellulose acetate butyrate in 310g of ethyl lactate, add 0.01g of non-ionic fluorocarbon surfactant after complete dissolution, stir and mix until completely dissolved, then add 0.2g of leveling agent in turn (TEGO Glid 130), 0.1g rheology modifier (BYK-431), and then add 660g of ethanol solution containing 5g of nano-silver wires, wherein the average diameter of nano-silver wires is 40nm, the length is 30-50μm, and the aspect ratio exceeds 600, add 2g of anti-sedimentation agent (dibutyl phthalate), grind in a ball mill for 4 hours, and then mix it evenly with a disperser for 10 minutes to obtain a nano-silver wire conductive ink. The concentration of the nano-silver wire is 5mg / ml .

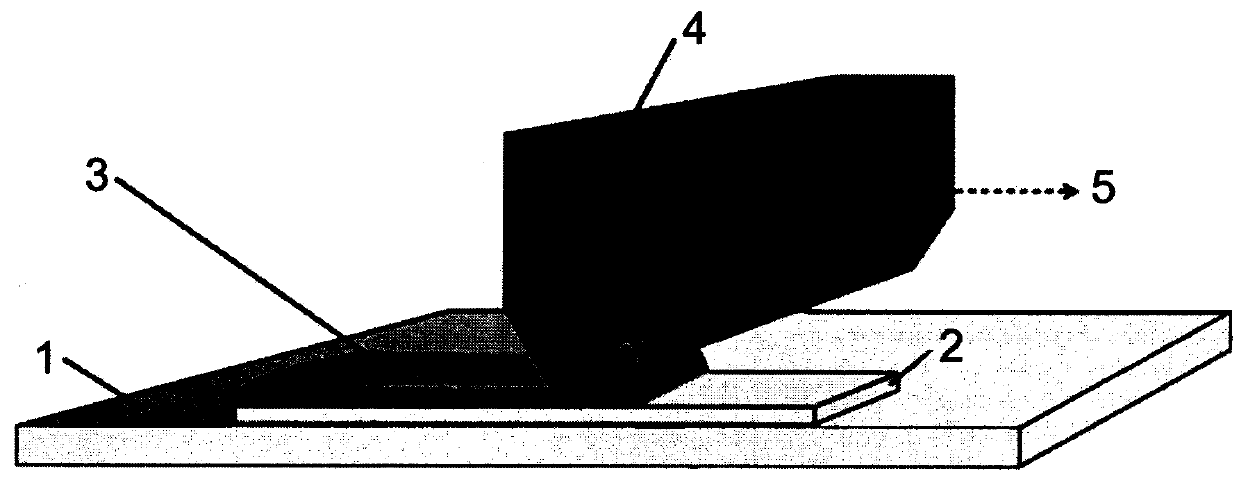

[0046] Polyethylene terephthalate (PET) is used as a transparent flexible substrate, its own light transmittance is 92%, and its thickness is 188 μm. The nano-silver wire conductive ink prepared above was evenly coated on the surfac...

Embodiment 2

[0052] Take 200g hydroxypropyl methylcellulose (HPMC) solution (3%, water and ethanol is 72:25), 0.75g Bayer curing agent W-8035 (40%), 10g Digao dispersant disperse760W (1%), 10g TEGO Wet 500 (1%), add mixed solvent (72:25 of water and ethanol) to 500g and stir evenly, add 0.5g rheology modifier BYK-425, 0.2g TEGO Wet270, 0.2g TEGO Glid110, Then take 262g of silver nanowire ethanol solution (average diameter 40nm, 5mg / ml), grind it in a ball mill for 4 hours, disperse it in a disperser for 10 minutes and stir evenly, and finally add ethanol to 1000g.

[0053] Using polycarbonate (PC) as a transparent flexible substrate, its own light transmittance is 92%, and its thickness is 125 μm. Apply the nano-silver wire conductive ink prepared above evenly on the surface of the PC substrate to form a uniform 15-30μm liquid film, dry it in a tunnel oven at 60°C, and heat it while pressing In the treatment, the heating temperature is 140° C., the heating pressure is 5 MPa, the pressure ...

Embodiment 3

[0055] Preparation of nano-silver wire conductive ink:

[0056] Get 20g mixed resin solution (solid content 2.73%, hydroxypropyl methylcellulose and aqueous polyester resin 830 solid content ratio 1: 1, solvent is water and ethanol 72: 25), the Bayer curing agent 2805 of 0.75g (40 %), 10g Digao dispersant TEGO Disperse760W (1%), 3g TTMAP, 10g Digao leveling agent TEGO Glid 100 (1%), add mixed solvent (water and ethanol is 72: 25) to 500g and stir evenly, then take 262g silver nanowire ethanol solution (average diameter 40nm, 5mg / ml) was stirred evenly, and ethanol was added to 1000g.

[0057] Using PET as a transparent flexible substrate, its own light transmittance is 92%, and its thickness is 100 μm. Apply the nano-silver wire conductive ink prepared above evenly on the surface of the PET substrate to form a uniform liquid film, and dry it in a tunnel oven at 120°C to obtain an overall conductive flexible transparent conductive ink without electrode patterns. membrane. Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com