Manufacturing method for color micro-light-emitting diode array substrate

A technology for micro-light-emitting diodes and array substrates, which is applied to electrical components, electrical solid-state devices, circuits, etc., can solve the problems of limiting the number of MicroLEDs, inability to realize multi-color MicroLED arrangement, and difficult to colorize LED display arrays, and achieves a manufacturing method. Simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0036] The present invention provides a method for manufacturing a color micro-light emitting diode array substrate. The color micro-light emitting diode array substrate includes a receiving substrate 20 and a color micro-light emitting diode array arranged on the receiving substrate 20; the receiving substrate 20 includes A plurality of monochrome pixel areas respectively corresponding to different colors, the color micro-light emitting diode array includes a plurality of monochrome micro-light-emitting diode arrays of different colors, and the monochrome micro-light-emitting diode array of each color is set on the pixel area.

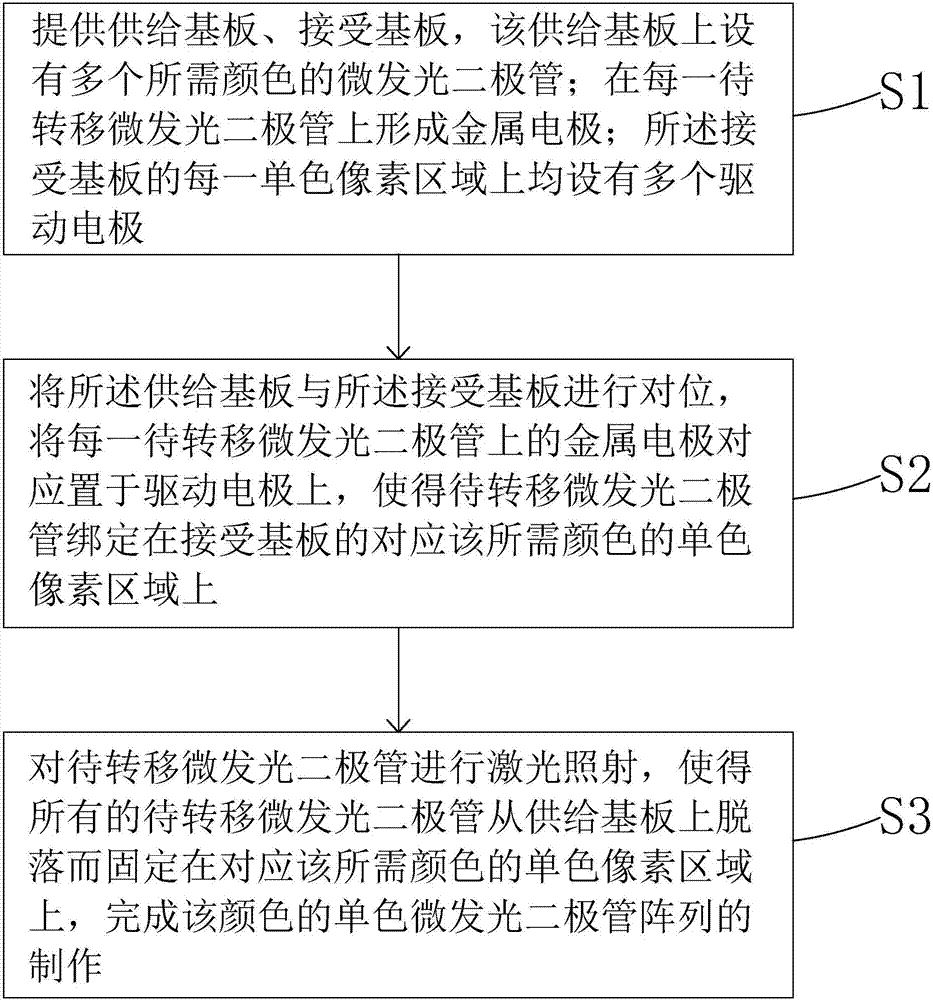

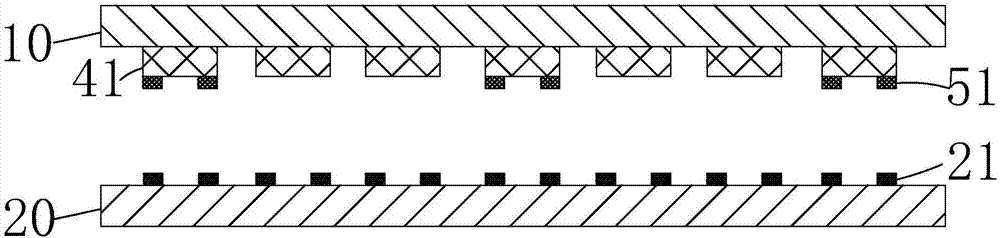

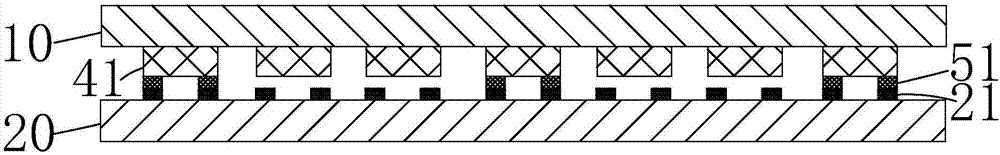

[0037] see figure 1 , wherein, the manufacturing method of the single-color micro-light-emitting diode array of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com