Process for recovering carbon materials of battery cathode

A technology of battery negative electrode and recycling method, applied in battery recycling, recycling technology, waste collector recycling, etc., can solve problems such as poor battery performance, and achieve the effects of high production efficiency, excellent cycle performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

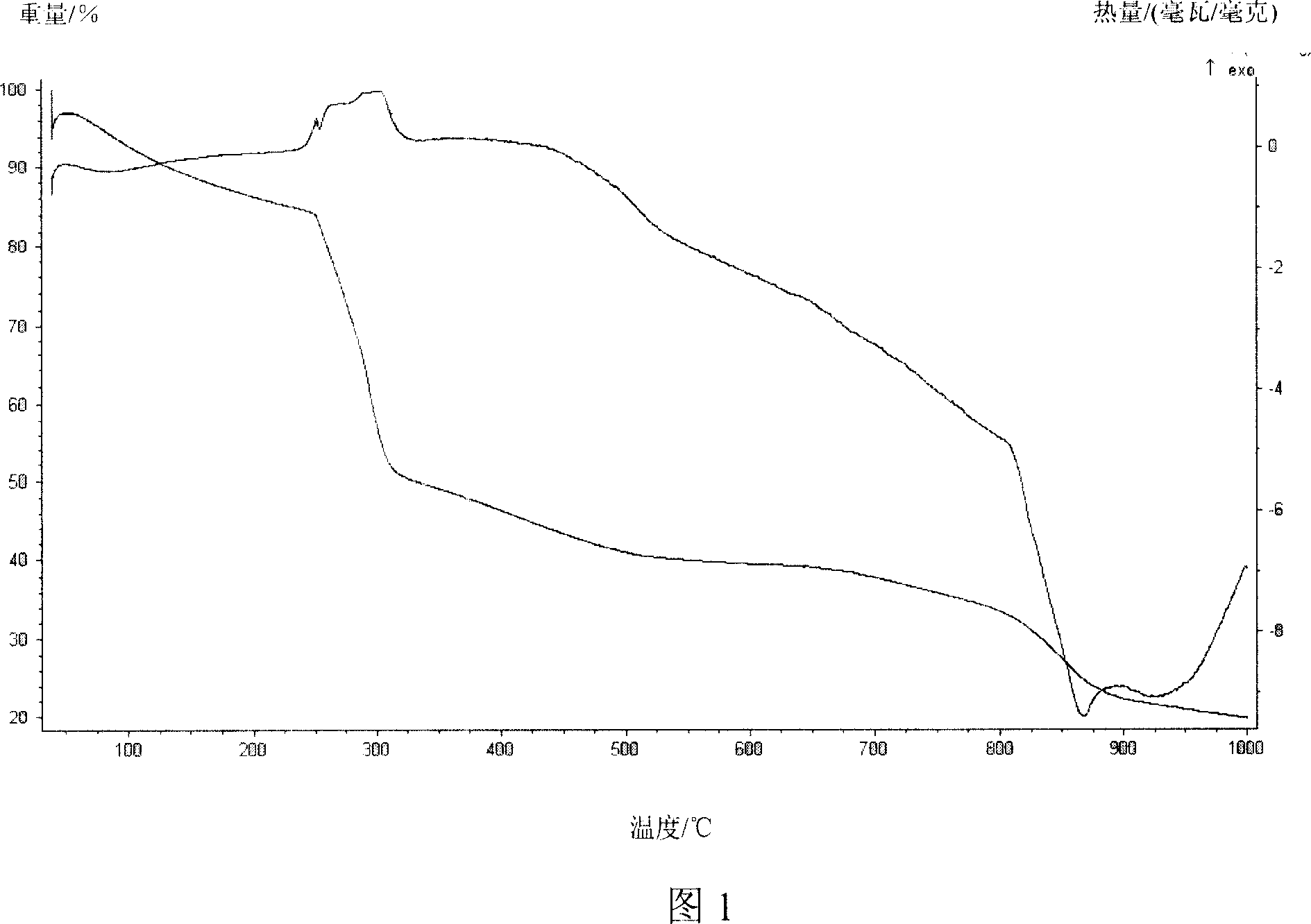

Image

Examples

Embodiment 1

[0029] This example is used to illustrate the recovery method of the battery negative electrode carbon material of the present invention.

[0030] Soak 1 kg of the lithium-ion secondary battery negative plate to be recovered in deionized water, the amount of deionized water is 5 liters, and the temperature is 90°C. After soaking for 24 hours, remove the current collector in the mixture with a mesh of 2 mm, then filter, then place the obtained solid matter in a high-temperature furnace, and heat it at 600°C for 6 hours under the protection of nitrogen, and then in Cool to room temperature under the protection of nitrogen to obtain graphite A1.

Embodiment 2

[0035] This example is used to illustrate the recovery method of the battery negative electrode carbon material of the present invention.

[0036] Soak 1 kg of the lithium-ion secondary battery negative plate to be recovered in an aqueous solution containing 1% AEO-9, the amount of the aqueous solution is 9 liters, and the temperature is 60° C. Stir for 10 minutes per hour at a speed of 300 rpm. Soak for 8 hours. The current collector in the mixture was removed with a mesh sieve having a mesh size of 2 mm, followed by filtration. On the filter device, the filtered solid matter was rinsed twice with deionized water, and the amount of each deionized water was 3 liters. Then bake the obtained solid substance in an oven at 100°C for 5 hours, cool it to room temperature in the oven, pulverize it in a pulverizer, and pass through a 120-mesh sieve; place the solid substance obtained above in a high-temperature furnace, Under protection, heat at 750°C for 3 hours, and then cool to ...

Embodiment 3

[0038] In addition to changing the soaking agent to an aqueous solution containing 3% AEO-6, and after obtaining the carbon material, soak it in 2 liters of deionized water for 20 minutes to remove the floating matter on the water surface, then filter it, and dry it in an oven at 200 ° C for 2 hours Except, all the other are identical with embodiment 2. Graphite A3 is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com