Fracturing pump power driving system

A power-driven and fracturing pump technology, which is applied to drilling driving devices, pumps, and engine components in the wellbore, can solve the problems of high procurement costs, high maintenance costs for engines and gearboxes, and high fuel consumption costs, and achieves The effect of reducing size and weight, ensuring efficient transmission, and reducing fuel costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

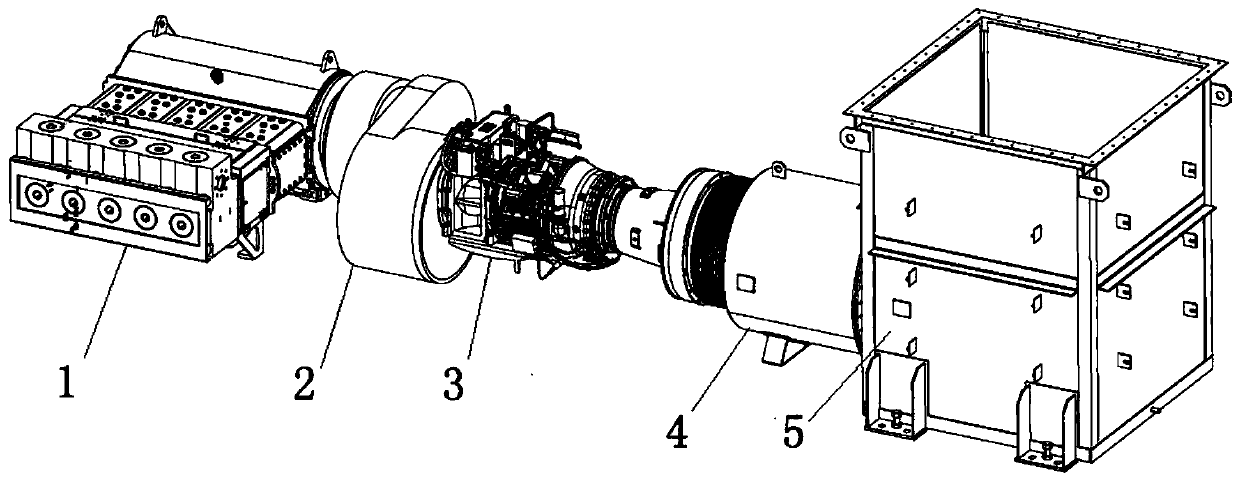

[0021] Such as figure 1 As shown, a fracturing pump power drive system includes a turbine engine 1, an exhaust system and a fracturing pump 3, one end of the turbine engine 1 is connected to the exhaust system, the other end of the turbine engine 1 is connected to the fracturing pump 3, and the fracturing pump 3 is connected to the other end of the turbine engine 1. The pump 3 is a fracturing pump 3 with its own reduction box 2 , and the turbine engine 1 is directly connected to the input end of the reduction box 2 on the fracturing pump 3 . The fracturing pump power drive system is driven by a turbine engine 1, and the turbine engine 1 can use 100% natural gas as fuel to replace diesel consumption in diesel engine driving, reducing fuel costs for customers. The turbine engine 1 itself has small size and light weight Advantages, greatly reducing the size and weight of the fracturing pump power drive system.

[0022] The turbine engine 1 is directly connected to the input end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com