Glass fiber reinforced modified polypropylene material and preparation method thereof

A polypropylene material and polypropylene technology, applied in the field of glass fiber reinforced modified polypropylene material and its preparation, can solve the problems of low warpage and heat preservation, high thermal conductivity, easy warpage and deformation, etc., and achieve low warpage Deformation, low density, effect of reduced density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

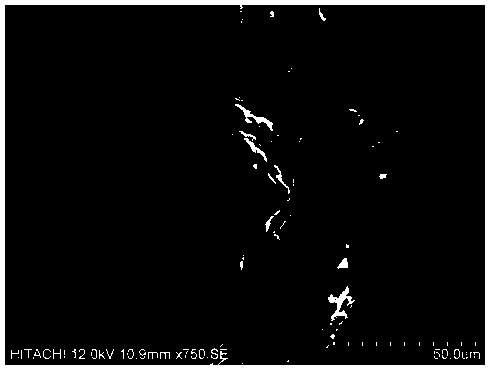

Image

Examples

preparation example Construction

[0035] Preparation of long glass fiber reinforced polypropylene masterbatch: mix polypropylene resin with processing aids such as antioxidants and extrude it into a high-temperature die through an extruder. The temperature of the die is controlled at 260-280°C; continuous glass Under the stretching effect of the traction equipment, the fiber is impregnated with the molten polymer in the extrusion die, then drawn, cooled, and then pelletized to obtain long glass fiber reinforced polypropylene masterbatch. The mass percentage of glass fiber in the masterbatch is 30% ~60%.

[0036] Preparation of chopped glass fiber reinforced polypropylene masterbatch: mix polypropylene resin, graft compatibilizer and additives uniformly at room temperature and pour them into the main feeding port of the twin-screw extruder, pour glass fiber chopped strands into into the side feeding port at the back end of the twin-screw extruder, the temperature of the extruder is controlled at 200~230°C, the ...

Embodiment 1

[0038] Mix 54 parts of polypropylene resin, 5 parts of PP-g-MAH graft compatibilizer, 0.4 part of antioxidant 1010, 0.4 part of antioxidant 168, and 0.2 part of erucamide lubricant at room temperature with a high mixer , the obtained mixture was poured into the main feeding port of the twin-screw extruder, and 40 parts of hollow glass microspheres (density 0.4g / cm 3 , with an average particle size of 15um) poured into the side feeding port at the rear end of the twin-screw extruder, controlling the temperature of the extruder at 200~230°C, and extruding the mixture through the twin-screw extruder to obtain glass micropearl grain. At room temperature, the long glass fiber reinforced polypropylene masterbatch with a glass fiber content of 50% and the hollow glass microbead masterbatch prepared above are evenly mixed in a ratio of 50:50 parts by weight to obtain a glass fiber reinforced modified polypropylene masterbatch. Acrylic material.

[0039] In this embodiment, hollow gl...

Embodiment 2

[0041] Mix 54 parts of polypropylene resin, 5 parts of PP-g-MAH graft compatibilizer, 0.4 part of antioxidant 1010, 0.4 part of antioxidant 168, and 0.2 part of erucamide lubricant at room temperature with a high mixer , the obtained mixture is poured into the main feeding port of the twin-screw extruder, and 40 parts of hollow glass microspheres (density 0.3g / cm 3 , with an average particle size of 10um) poured into the side feeding port at the rear end of the twin-screw extruder, control the temperature of the extruder at 200~230°C, and extrude the mixture through the twin-screw extruder to obtain glass micropearl grain. At room temperature, the long glass fiber reinforced polypropylene masterbatch with a glass fiber content of 50% and the hollow glass microbead masterbatch prepared above are evenly mixed in a ratio of 40:60 parts by weight to obtain a glass fiber reinforced modified polypropylene masterbatch. Acrylic material.

[0042] In this embodiment, hollow glass micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com