A kind of dipping device and method

A dipping device and a dipping technology, applied in the direction of coating, etc., can solve the problems that the residence time of the glue solution cannot be used in time, cannot ensure sufficient dipping, and reduce the utilization rate of the glue solution, so as to improve the utilization rate of the glue solution , easy to control, and the effect of saving the amount of glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

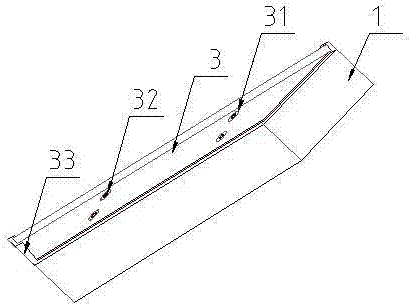

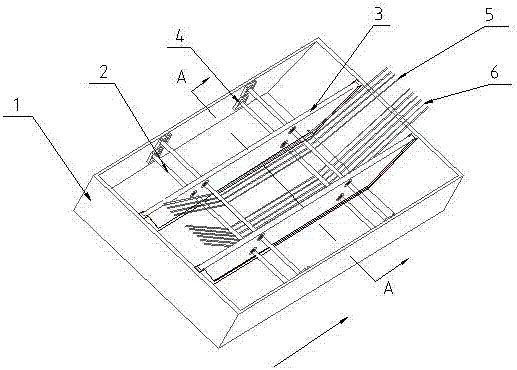

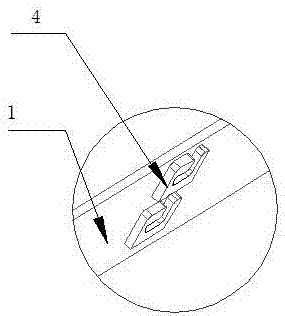

[0022] Embodiment: refer to attached Figure 1-4 A dipping device shown includes a dipping tank 1, and a pair of longitudinal and opposite limit baffles 3 are arranged in the dipping tank 1, and the bottom and two ends of each limit baffle 3 are Both are in sliding contact with the inner surface of the dipping tank 1, and there are two sets of yarn pressing rods 2 that pass through the limit baffle 3 and are arranged side by side in the dipping tank 1, respectively divided into There are 2 groups of front yarn pressing rods and 2 groups of rear yarn pressing rods, the yarn pressing rods 2 and the limit baffles 3 are perpendicular to each other.

[0023] In the present invention: each set of said yarn pressing rods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com