Production process of fiberglass threads used for rubber reinforcement

A technology of glass fiber and production process, which is applied in the field of production process of glass fiber cord for rubber reinforcement, which can solve problems such as broken wires, glass fiber bundle damage, and reduced physical properties, and achieve quality improvement, quality improvement, and improved operation environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1: the manufacture method of RFL treating agent

[0063]Get 100 parts of vinylpyridine latex (trade name Nipol2518FS ZEON, 40% by weight, ZEON CORPORATION), 11.1 parts of chlorosulfonated polyethylene (commodity is [CSM450], 40% by weight, manufactured by Sumitomo Seika Chemicals), 6.7 parts RF polymer (INDSPEC company, 7% by weight), deionized water, and the above were mixed and reacted together to prepare an RFL treatment agent with a concentration of about 30%. (Note: the above components are parts by weight of solids)

Embodiment 2

[0064] Embodiment 2: the manufacture method of OVC treatment agent

[0065] 10 parts of chlorosulfonated polyethylene are used as halogenated compounds, 5 parts of polyisocyanate, 2 parts of p-, p'-bibenzoylbenzoquinone dioxime are used as vulcanizing agents, 5 parts of carbon black are used as inorganic filler materials, and toluene is used as Solvent, the OVC treatment agent with a concentration of 10% is prepared by mixing the above together. (Note: the above components are parts by weight of solids)

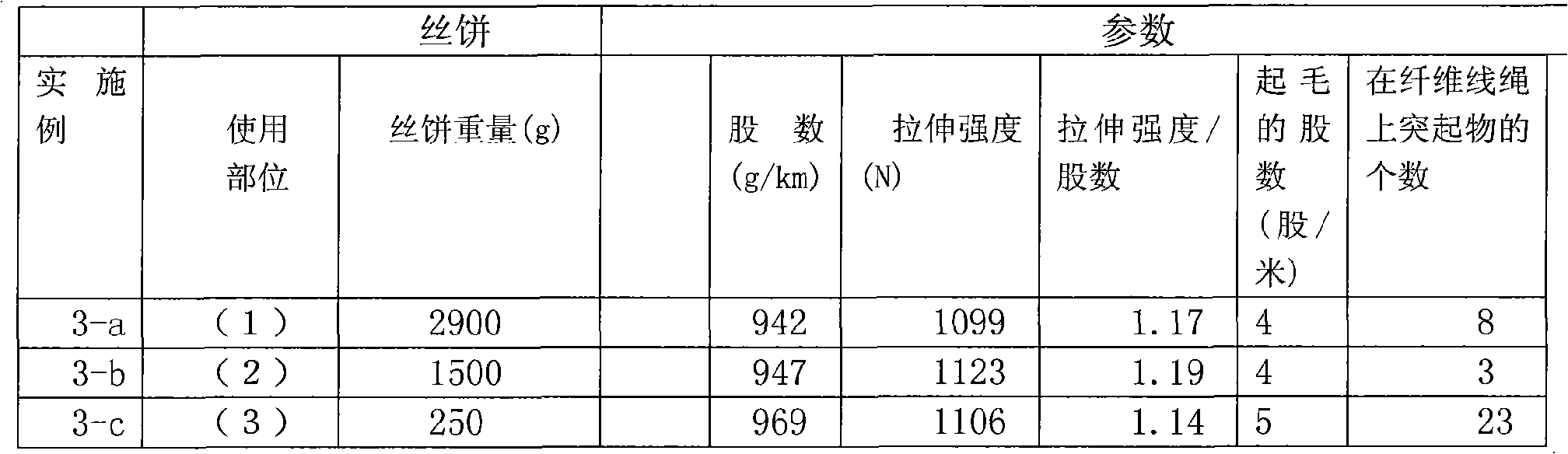

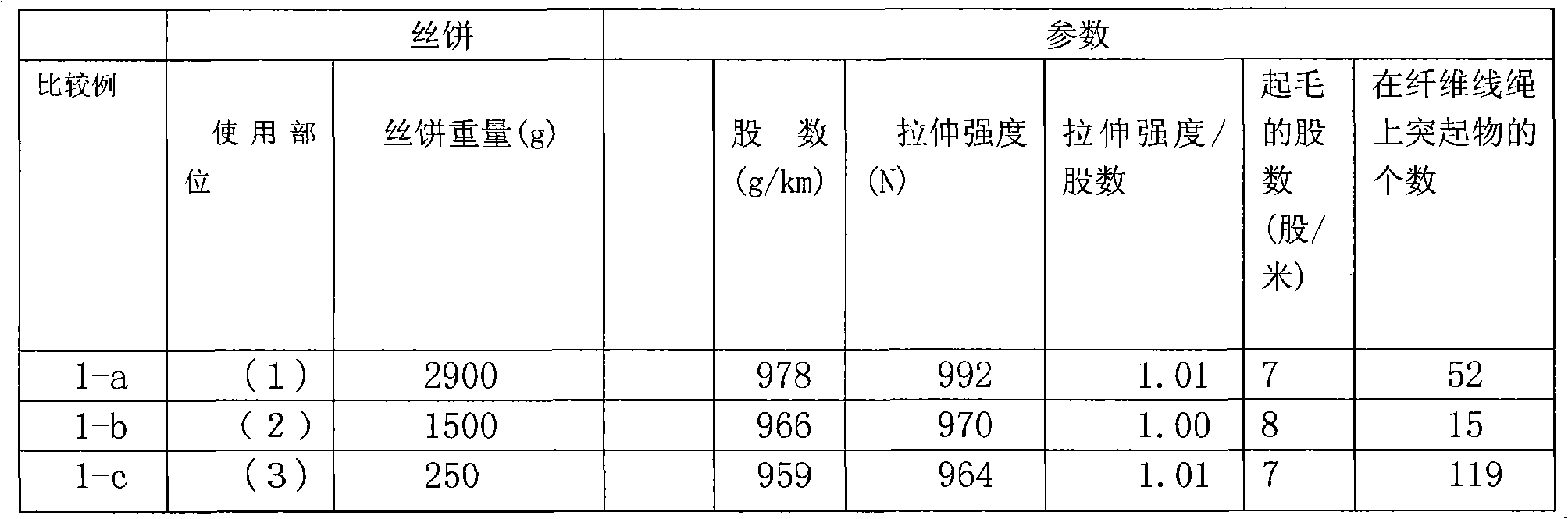

Embodiment 3-a

[0067] Take 600 strands of high-strength (S-grade glass fiber) glass fiber monofilaments with an average diameter of 7 microns, use the slurry mainly containing aminosilane coupling agent for sizing and assembly, and control the tension of the glass fiber bundles to 74g / strand. Through the wire winding device, after winding the wire, make it dry to obtain a fiber bundle silk cake with a mass of 3000g, then pull out the fiber bundle from the innermost side of the silk cake, remove about 100g of the part, and pull it from the remaining 2900g part 500M, through the impregnation tank filled with the RFL treatment agent prepared in Example 1, the drawn glass fiber bundles are continuously impregnated one by one. Make the RFL treatment agent adhere to the fiber bundle and penetrate into it. At this time, the tension of the glass fiber bundle was 70 g / strand.

[0068] Then pass the fiber bundle through an oven at 200-300° C. and continue heating for 1 minute to dry and solidify the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com