A glass fiber reinforced plastic winding pipe processing equipment

A technology for processing equipment and winding pipes, applied in the field of glass fiber reinforced plastic winding pipe processing equipment and processing equipment, can solve the problems of small application range of molds, low applicability, small adjustable range, etc., and achieves strong applicability and practicability. Internal structure The effect of tightness and improved processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

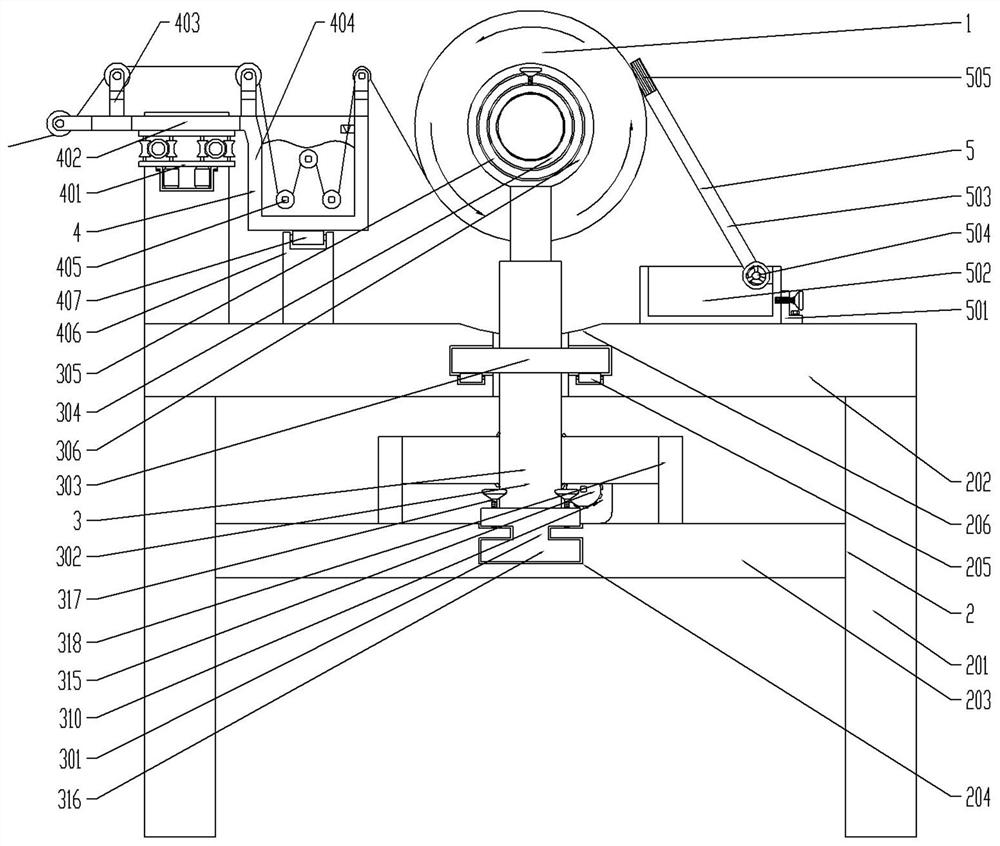

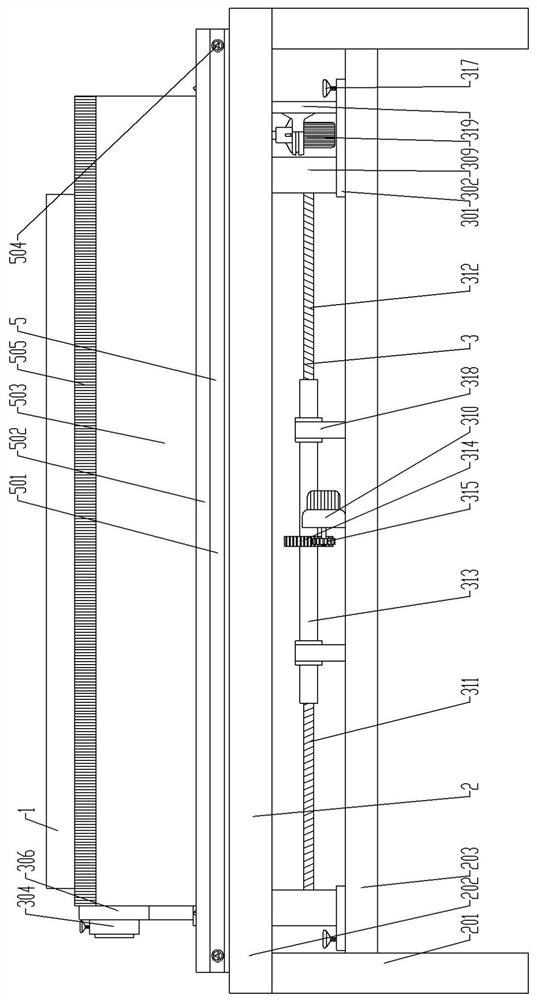

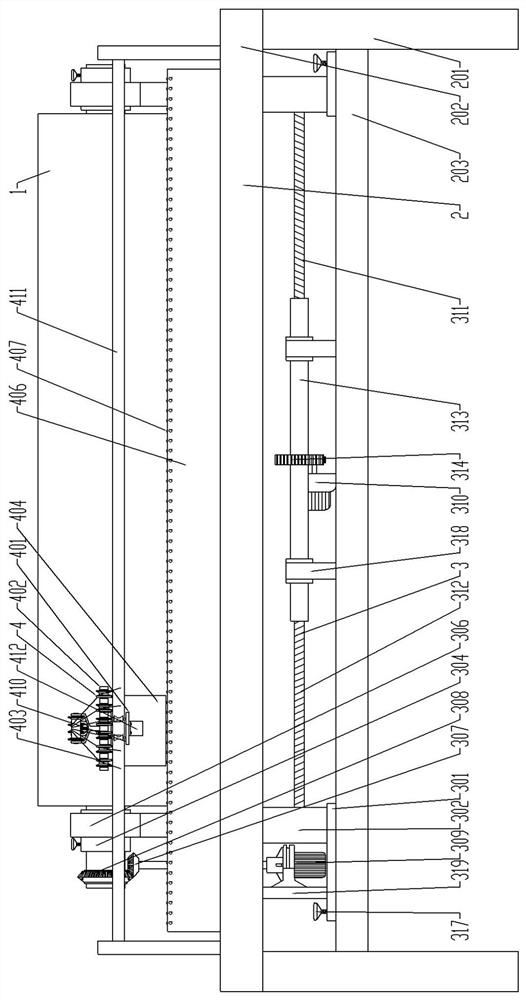

[0032] see figure 1 , figure 2 , image 3 , Figure 5 , a fiberglass winding pipe processing equipment, including a winding pipe mold 1, and also includes a support assembly 2, a retention assembly 3 and a wire feeding dipping assembly 4, and the retention assembly 3 is slidably arranged on the support assembly 2 In the middle, the wire feeding dipping assembly 4 is arranged on the supporting assembly 2, and the supporting assembly is used to support the retention assembly and the wire feeding dipping assembly. The supporting assembly 2 includes legs 201, upper support plate 202 and a lower support plate 203, the legs 201 are arranged at the corners of the upper support plate 202, the lower support plate 203 is fixedly arranged on the legs 201, the upper support plate 202 and the middle part of the lower support plate 203 Both are provided with chute 204, the chute of the upper support plate and the lower support plate are used for limiting the retention assembly, and the ...

Embodiment 2

[0044] The same as embodiment 1 will not be repeated, the difference is:

[0045] The upper support plate 202 is also provided with a scraping mechanism 5, the scraping mechanism 5 includes a retaining angle plate 501, a glue collecting groove 502 and a squeegee plate 503, and the retaining angle plate 501 is fixed to the upper supporting plate by bolts 202, easy to disassemble and install, the retaining angle plate 501 is connected to the glue collecting tank 502 through the retaining hand wheel 504, and connected through the retaining hand wheel, it is convenient to remove it to collect the glue recovered inside the glue collecting tank. The squeegee 503 is arranged inside the rubber collecting tank 502. The squeegee 503 and the rubber collecting tank 502 are hingedly connected. The hinged connection can adjust the angle of hanging overtime. It is suitable for winding pipes of various specifications. Connected by adjusting the hand wheel 317, the end of the scraper 503 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com