A chain dipping equipment

一种浸漆、设备的技术,应用在对表面涂布液体的装置、涂层等方向,能够解决浸漆不充分、易产生次品等问题,达到浸漆充分、设备结构简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the solutions of the present invention, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention.

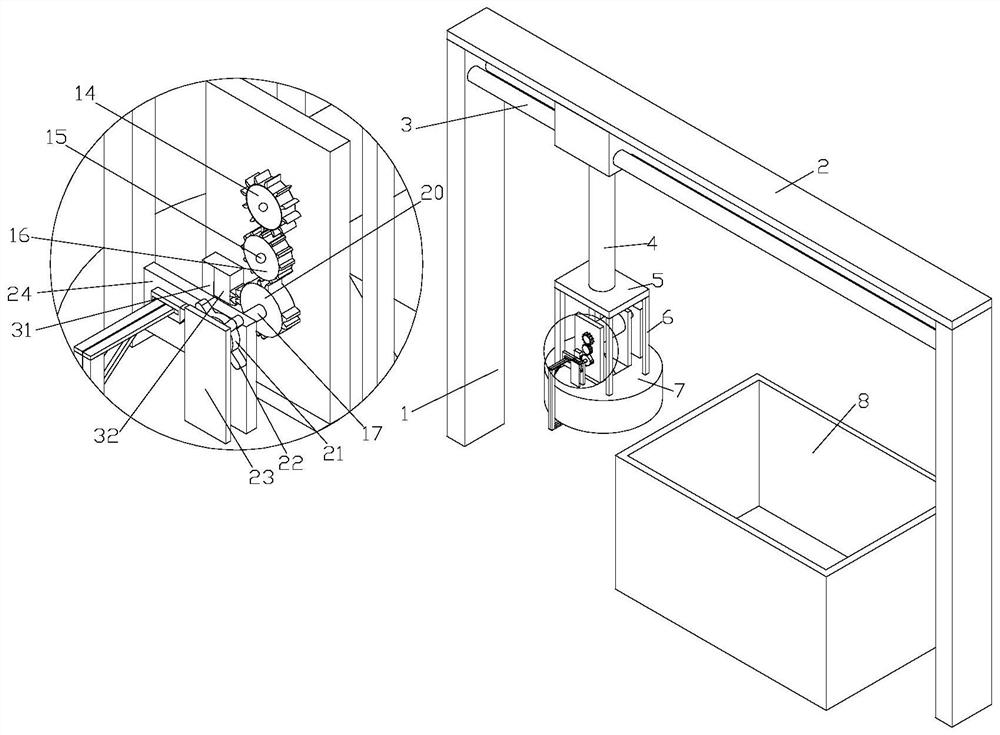

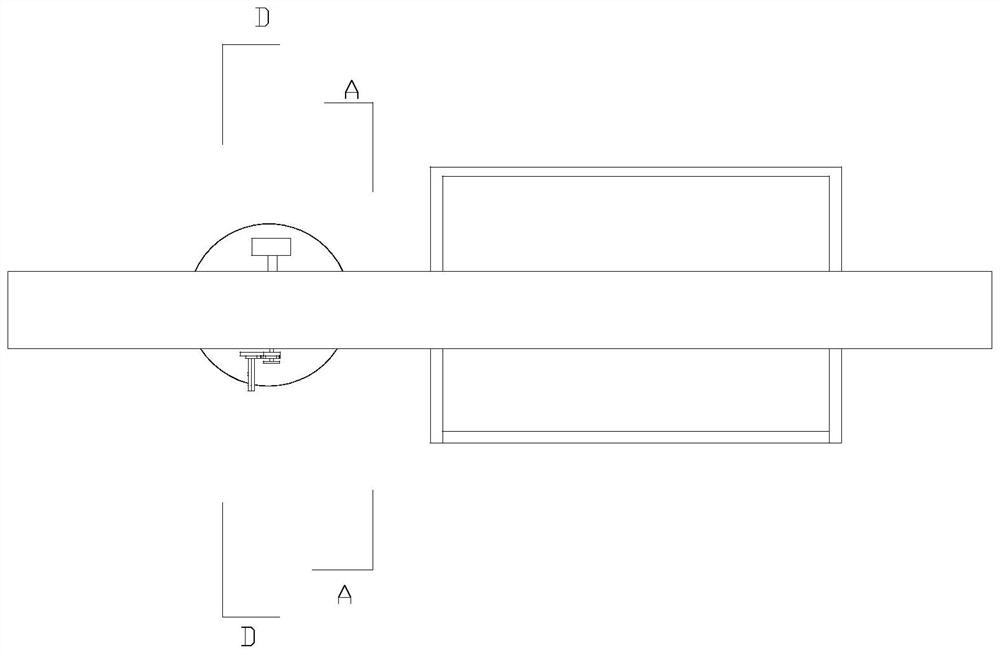

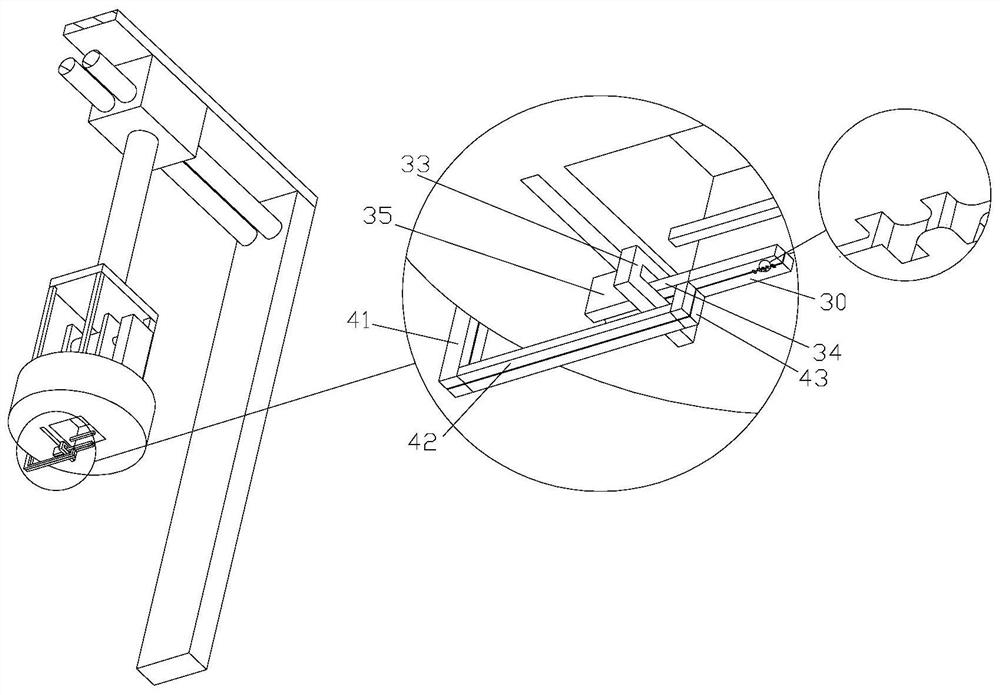

[0022] Such as Figure 1-8 As shown, in order to achieve the above object, the present invention adopts the following technical solutions: a chain paint dipping equipment, including two vertical boards 1, a top plate 2 fixedly arranged on the upper end faces of the two vertical boards 1, fixedly arranged between the two vertical boards 1 The rodless cylinder 3, the cylinder 4 fixedly arranged on the output end of the rodless cylinder 3, the support plate 5 fixedly arranged on the output end of the cylinder 4, the four vertical rods 6 fixedly arranged on the lower end surface of the support plate 5 respectively, fixedly arranged on four The disk 7 on the lower end surface of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com